Water-boiled peanut and preparation method thereof

A technology of boiled peanuts and peanuts, which is applied in the field of food processing, can solve problems such as easy breeding of spoilage bacteria or even pathogenic bacteria, easy destruction of peanut nutrients, and adverse effects on product quality, and achieves various flavors, long shelf life, and guaranteed The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

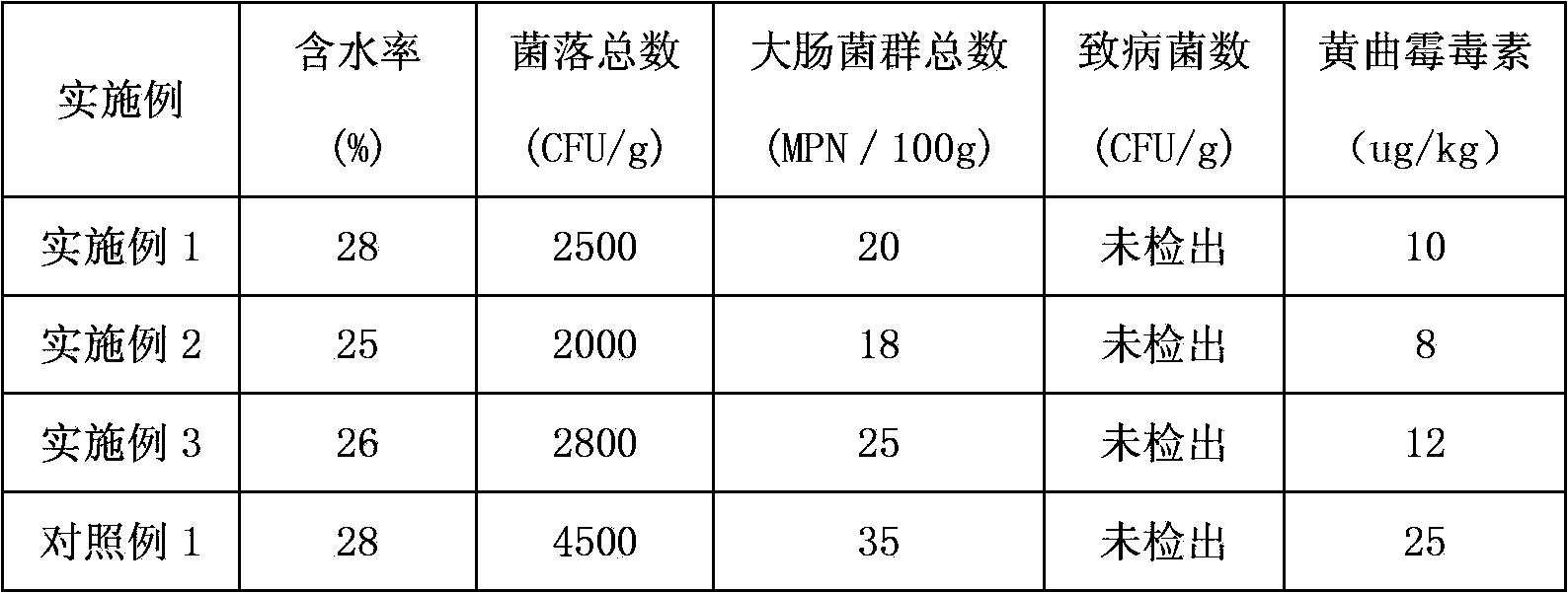

Examples

Embodiment 1

[0030] 1. Preparation of biological preservatives and seasonings:

[0031] Prepare the biological preservative according to the following proportions by weight:

[0032] 30 parts of ε-polylysine, 10 parts of nisin, 30 parts of natamycin, 7 parts of lysozyme, 10 parts of subtilisin, 0.5 parts of ascorbic acid, 5 parts of ginkgo biloba extract, 2.5 parts of tea polyphenols part, 5 parts of chitosan;

[0033] Prepare the seasoning according to the following proportions by weight:

[0034] 10 parts of table salt, 3 parts of star anise, 2 parts of Chinese pepper;

[0035] Except preparing biological preservative by above-mentioned proportioning by weight, the biological preservative of following proportioning by weight is also applicable to the present invention:

[0036] ε-polylysine 30-40 parts, nisin 10-14 parts, natamycin 20-30 parts, lysozyme 4-8 parts, subtilisin 10-13 parts, ascorbic acid 0.3-0.6 parts , 3-6 parts of Ginkgo biloba extract, 2-4 parts of tea polyphenols, 4...

Embodiment 2

[0056] 1. Preparation of biological preservatives and seasonings:

[0057] Prepare the biological preservative according to the following proportions by weight:

[0058] 50 parts of ε-polylysine, 15 parts of nisin, 5 parts of natamycin, 1 part of lysozyme, 20 parts of subtilisin, 1 part of ascorbic acid, 2 parts of ginkgo biloba extract, 5 parts of tea polyphenols part, 1 part of chitosan;

[0059] Prepare the seasoning according to the following proportions by weight:

[0060] 5 parts of table salt, 1 part of fennel, 1.5 parts of cinnamon, 1 part of bay leaves, 2 parts of peppercorns;

[0061] Except preparing biological preservative by above-mentioned proportioning by weight, the biological preservative of following proportioning by weight is also applicable to the present invention:

[0062] ε-polylysine 40-50 parts, nisin 14-17 parts, natamycin 5-10 parts, lysozyme 1-4 parts, subtilisin 16-20 parts, ascorbic acid 0.6-1 parts , Ginkgo biloba extract 1-3 parts, tea polyp...

Embodiment 3

[0076] 1. Preparation of biological preservatives and seasonings:

[0077] Prepare the biological preservative according to the following proportions by weight:

[0078] ε-polylysine 26.4 parts, nisin 20 parts, natamycin 15 parts, lysozyme 10 parts, subtilisin 15 parts, ascorbic acid 0.1 part, ginkgo biloba extract 10 parts, tea polyphenol 1 part, 2.5 parts of chitosan;

[0079] Prepare the seasoning according to the following proportions by weight:

[0080] 8 parts of salt, 1 part of licorice, 1.5 parts of star anise, 2 parts of white sugar;

[0081] Except preparing biological preservative by above-mentioned proportioning by weight, the biological preservative of following proportioning by weight is also applicable to the present invention:

[0082] ε-polylysine 25-30 parts, nisin 17-20 parts, natamycin 10-20 parts, lysozyme 9-10 parts, subtilisin 13-16 parts, ascorbic acid 0.1-0.3 parts , Ginkgo biloba extract 6-10 parts, tea polyphenols 1-2 parts, chitosan 2-4 parts; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com