A double-sided coated drug-eluting stent containing a magnetic bottom layer and its manufacturing method

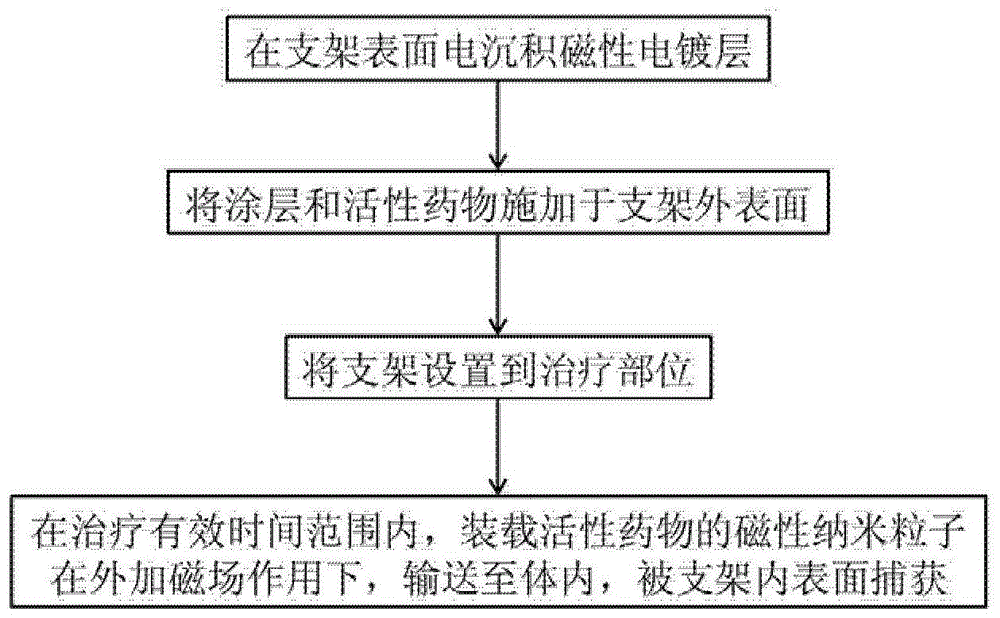

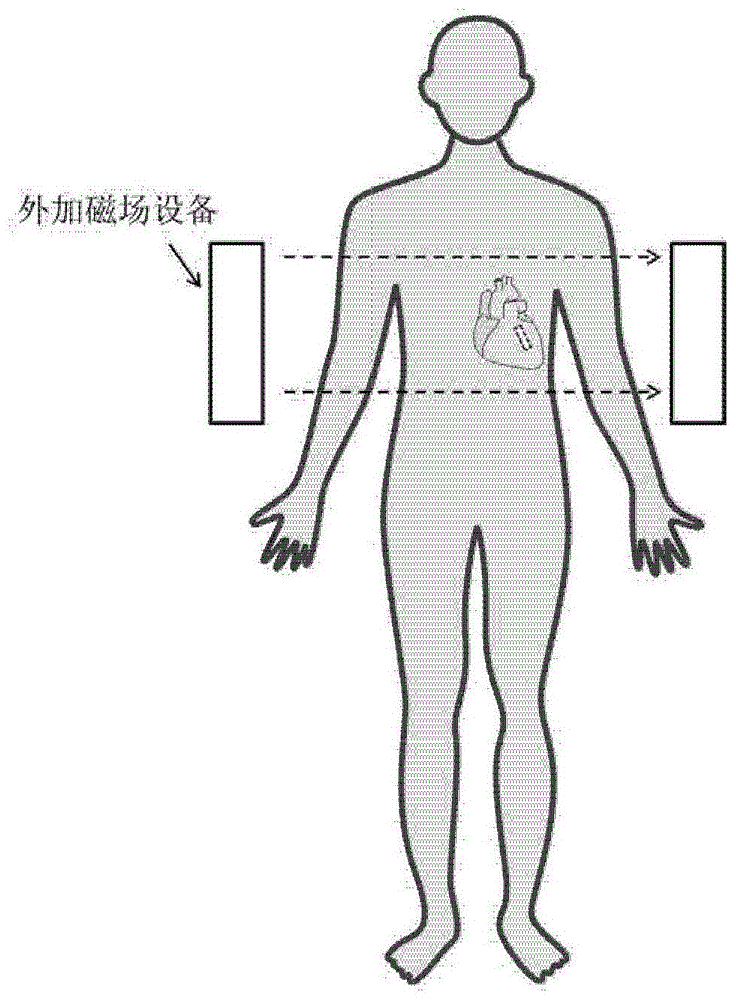

A technology for eluting stents and active drugs, applied in the field of medical devices, can solve the problems of limited adsorption capacity of magnetic nanoparticles, no practical application of magnetic nanoparticles, limited magnetic response ability, etc., and achieve the effect of dual-target release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) The material of the bracket is stainless steel, and the metal bracket is prepared by laser cutting technology for use.

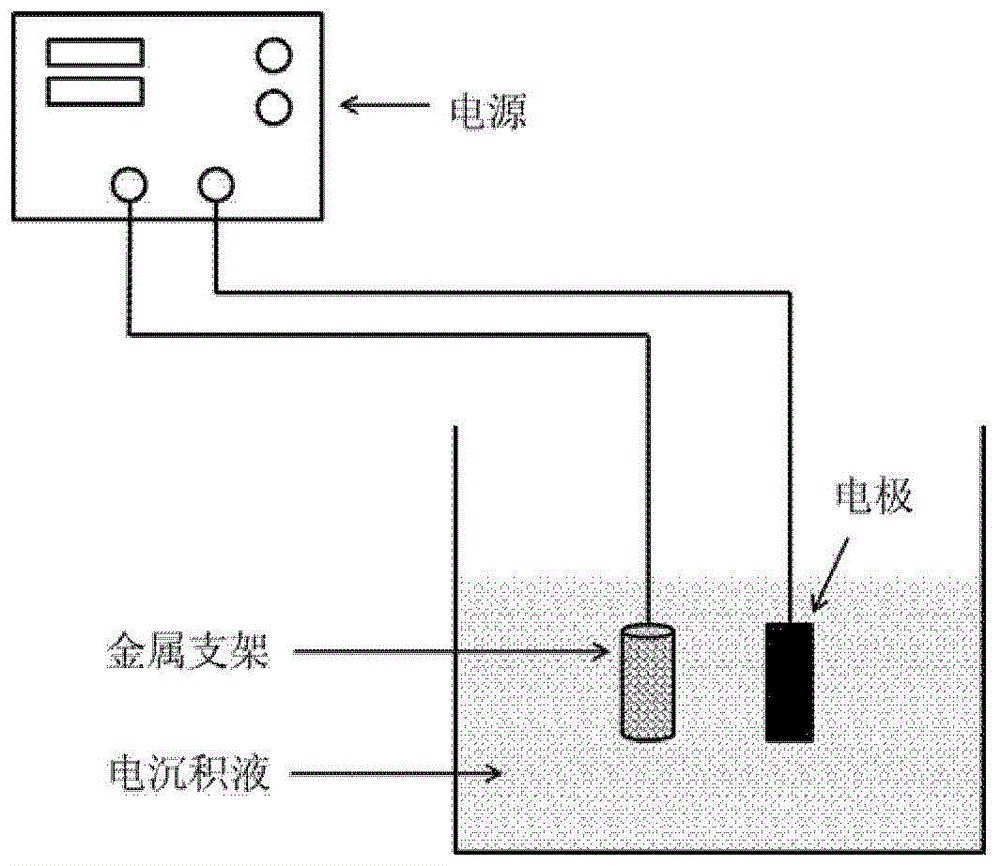

[0048] (2) Electrodeposition is used to deposit a layer of Co / Ni hard magnetic bottom layer on the inner and outer surfaces of the above-mentioned metal support. The process includes: preparing 0.2M NiCl 2 , (0.1-0.206) M CoCl 2 , 0.4M H 3 BO 3 , 0.7M NaCl, and (0.0097-0.0485) M saccharin (Sigma, MO) 100 ml electrodeposition solution, pH 3-4, press figure 2 The electrodeposition process was carried out as shown to obtain a metal stent with a magnetic underlayer.

[0049] (3) Take 0.1g poly D,L-lactic acid (PDLLA, weight average molecular weight range is 30,000-140,000), dissolve it in 10ml n-propyl acetate at room temperature, prepare a uniform solution, and then add 0.1g rapamycin Mix the ingredients evenly, accurately spray the prepared solution onto the outer surface of the stent containing the magnetic bottom layer, dry the stent in a vac...

Embodiment 2

[0056] (1) The stent is made of stainless steel, and the bare metal stent is prepared by laser cutting technology for use.

[0057] (2) Deposit a layer of Co / Ni / P hard magnetic bottom layer on the inner and outer surfaces of the above-mentioned metal bracket by electrodeposition method, and the process includes: preparing a 0.2M NiCl 2 , (0.1-0.206) M CoCl 2 , (0.047-0.566) M NaH 2 PO 2 , 0.4M H 3 BO 3 , 0.7M NaCl, and (0.0097-0.0485) M saccharin (Sigma, MO) 100 ml electrodeposition solution, pH 3-4, press figure 2 The electrodeposition process was carried out as shown to obtain a metal stent with a magnetic underlayer.

[0058] (3) Take 0.1g poly D,L-lactic acid (PDLLA, weight average molecular weight range is 30,000-140,000), dissolve it in 10ml n-propyl acetate at room temperature, prepare a uniform solution, and then add 0.1g rapamycin The ingredients were mixed evenly, and the prepared solution was accurately sprayed onto the outer surface of the stent, and the ste...

Embodiment 3

[0066] (1) The stent is made of stainless steel, and the bare metal stent is prepared by laser cutting technology for use.

[0067] (2) Deposit a layer of Co / Ni soft magnetic bottom layer on the inner and outer surfaces of the above-mentioned metal bracket by electrodeposition method, and the process includes: preparing 0.45M NiCl 2 , 0.65M CoCl 2 、30g / dm -3 h 3 BO 3 and trace saccharin (Sigma, MO) of 100 ml electrodeposition solution, press figure 2 The electrodeposition process was carried out as shown to obtain a metal stent with a magnetic underlayer.

[0068] (3) Take 0.1g poly D,L-lactic acid (PDLLA, weight average molecular weight range is 30,000-140,000), dissolve it in 10ml n-propyl acetate at room temperature, prepare a uniform solution, and then add 0.1g rapamycin The ingredients were mixed evenly, and the prepared solution was accurately sprayed onto the outer surface of the stent, and the stent was dried in a vacuum oven, and sterilized by ethylene oxide for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com