Extra-coarse grain tungsten carbide powder with narrow particle size distribution and preparation method thereof

A narrow particle size distribution, tungsten carbide technology, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problems of difficult to obtain high performance, poor use effect and life, wide particle size distribution, etc., to achieve high toughness, The effect of good thermal fatigue resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

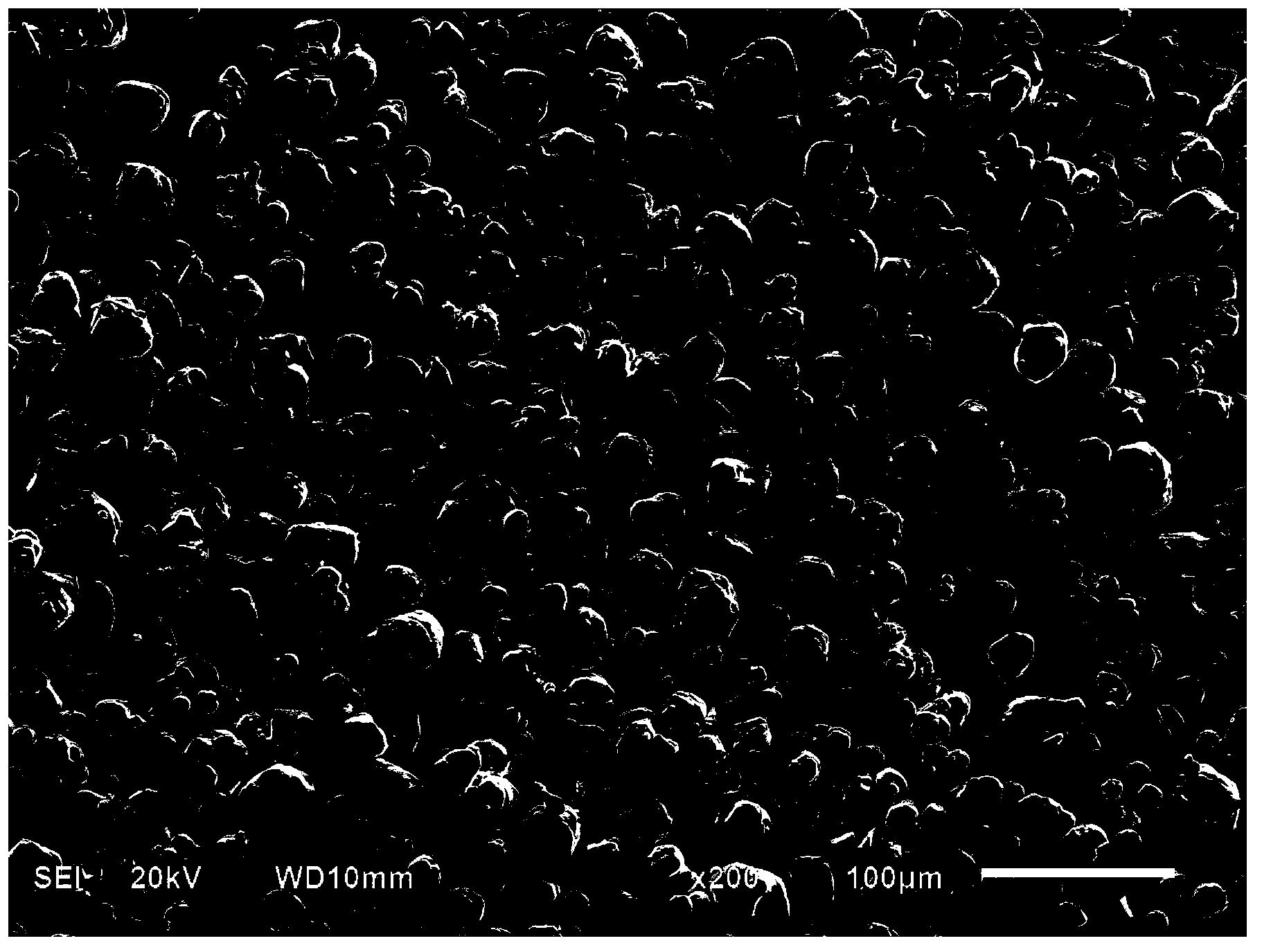

[0025] The preparation method of the ultra-coarse tungsten carbide powder with narrow particle size distribution of the present invention comprises the following steps:

[0026] (1) High-temperature hydrogen reduction of tungsten oxide: Select tungsten oxide powder with a Fischer particle size (Fsss particle size) greater than 10 μm for high-temperature hydrogen reduction to make coarse W powder. The tungsten oxide mainly adopts WO 3 、WO 2.9 Or a mixture of the two, the high-temperature hydrogen reduction temperature ranges from 1000°C to 1300°C.

[0027] (2) Super-coarse tungsten powder hard aggregate crushing: the "hard aggregate" formed in the coarse tungsten powder is crushed, and the "hard aggregate" crushing mainly adopts at least one of stirring ball mill, rolling ball mill and jet mill.

[0028] (3) Grading of tungsten powder particle size: Classify the ultra-coarse tungsten powder after crushing by airflow or passing through a vibrating sieve to remove finer and par...

Embodiment 1

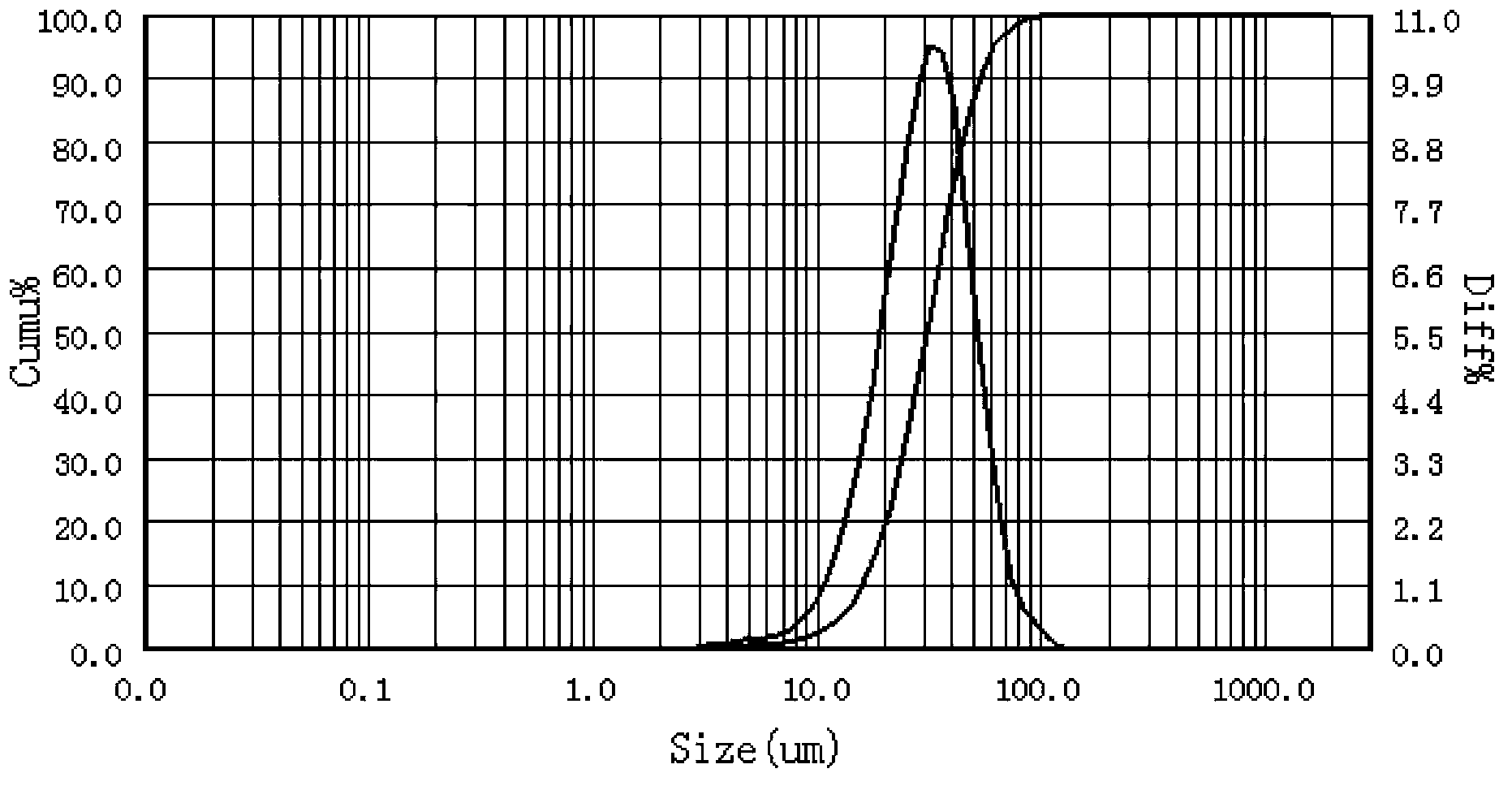

[0033] The narrow particle size distribution Fischer particle size (Fsss particle size) is 15μmWO 3 The powder was reduced at 1300°C for 3 hours to obtain coarse W powder. Put 50kg of high-purity coarse tungsten powder reduced by high temperature into the stainless steel stirring ball mill cylinder, the ball-to-material ratio is 2:1, and pass through the vibrating sieve after ball milling for 4 hours, and the Fischer particle size of 26 μm can be obtained between 200 mesh and 270 mesh sieves. Coarse tungsten powder. The resulting coarse tungsten powder was mixed with 6.17wt% carbon and ball milled for 2 hours. Then put it into a graphite boat and carbonize in a vacuum intermediate frequency induction carbonization furnace. The carbonization process parameters are 1700 ° C for 4 hours, then heat up to 2400 ° C for 3 hours, and then discharge the material after cooling to the temperature that can be released from the furnace. The obtained tungsten carbide agglomerate was crush...

Embodiment 2

[0035]The narrow particle size distribution Fischer particle size (Fsss particle size) is 10μmWO 2.9 Powder, reduced at 1000°C for 5 hours to obtain coarse W powder. Put 50kg of high-purity coarse tungsten powder reduced by high temperature into the stainless steel ball mill cylinder of the rolling ball mill, the ball-to-material ratio is 2:1, mill for 3 hours, decompose and break the "hard aggregates" in the powder, and pass through a 200 mesh screen After cyclone airflow classification, fine tungsten powder is removed to obtain coarse tungsten powder with narrow particle size distribution. The particle size of 95wt% tungsten powder is between 12 μm and 56 μm. The obtained coarse tungsten powder is mixed with carbon black, the carbon content is 6.13wt%, and then 100 kg of materials per graphite boat is loaded into a vertical intermediate frequency induction high-temperature carbonization furnace, and carbonized in a hydrogen protective atmosphere at a carbonization temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com