Preparation method of pre-gelatinized starch-chitosan grafted copolymer flocculating agent for removing heavy metal ions in industrial wastewater

A technology of pregelatinized starch and graft copolymer, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc., can solve problems such as low solubility and poor flocculation performance, and achieve applicability The effect of strong and excellent environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

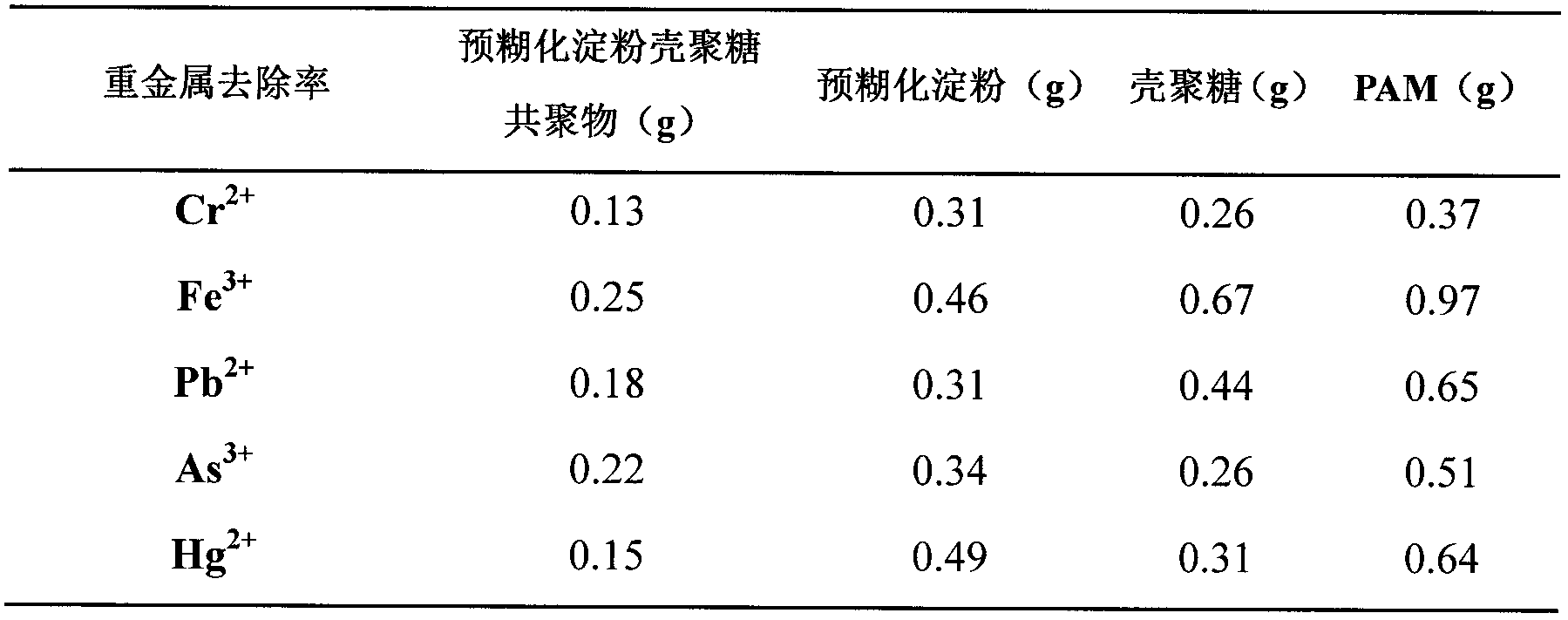

[0020] Example 1, pregelatinized starch: chitosan mass ratio is 2: 1, at 60°C, react for 8h when the initiator cerium ammonium nitrate amount accounts for 0.1% of the total mass, it is prepared, dried and crushed to 200 mesh spare. See Table 1 for the mass added to achieve a 50% heavy metal removal rate by decolorizing 1L of conventional textile printing and dyeing wastewater with a dye content of 1g / L.

[0021]

Embodiment 2

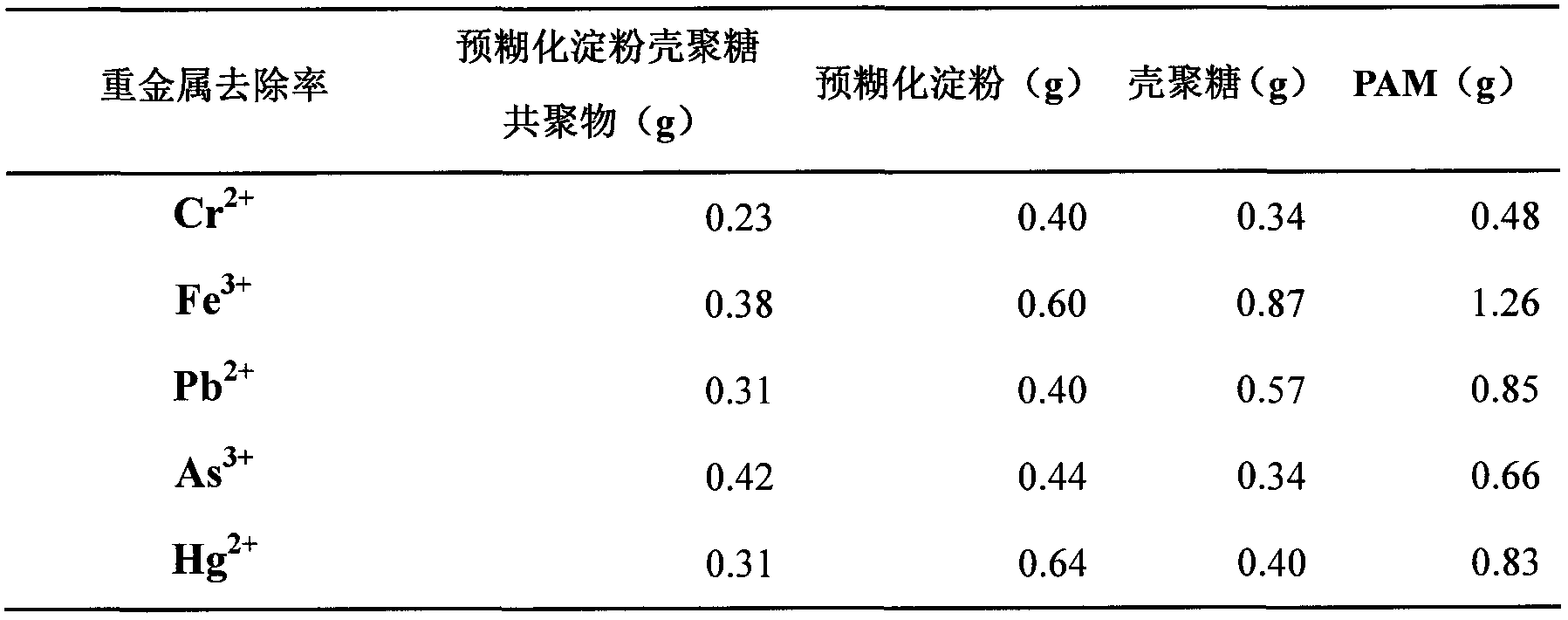

[0022] Embodiment two, pregelatinized starch: chitosan mass ratio is 3: 1, at 50 ℃, reaction 8h, when the amount of initiator initiator ammonium cerium nitrate accounted for 0.5% of the total mass, preparation generated, dried and crushed Up to 200 mesh for standby. See Table 2 for the mass added to 1L of industrial wastewater with a heavy metal ion content of 1g / L to achieve 75% removal of heavy metals.

[0023]

Embodiment 3

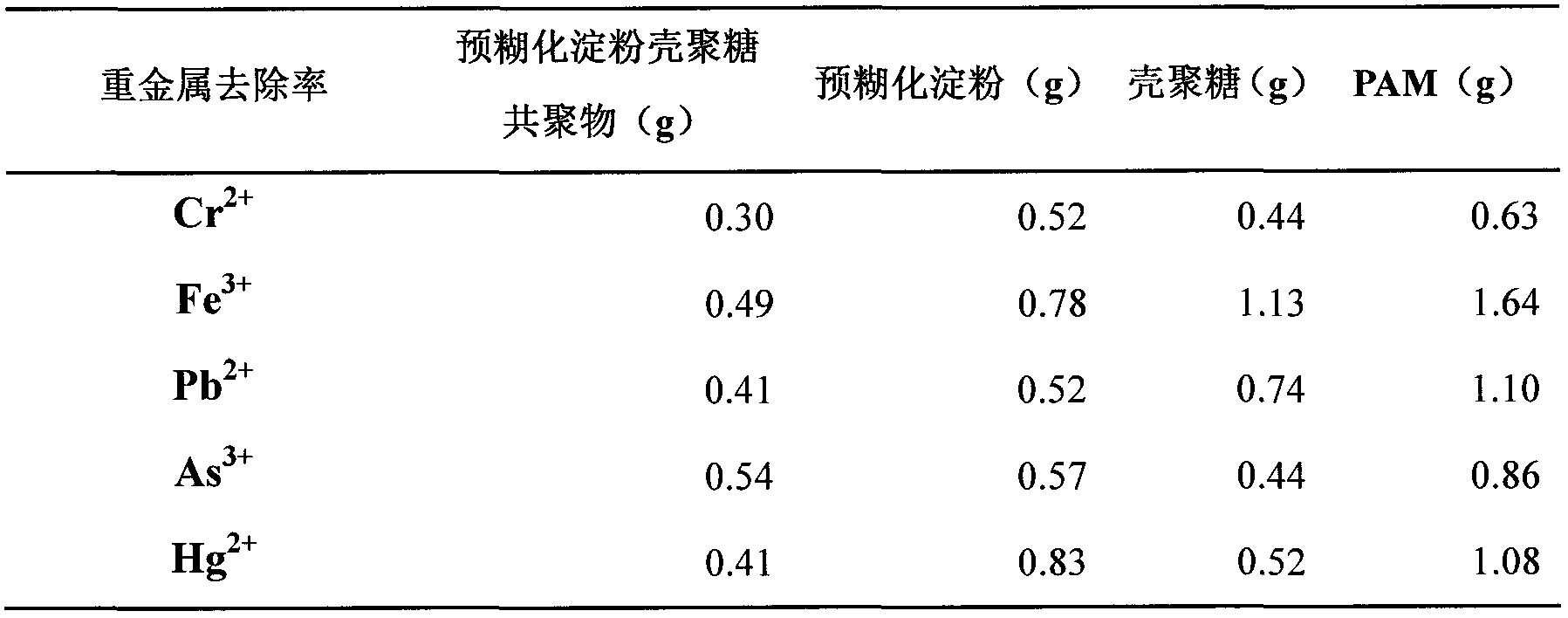

[0024] Embodiment three, pregelatinized starch: chitosan mass ratio is 4: 1, at 45 DEG C, react 8h, when initiator ceric ammonium nitrate consumption accounts for 1% of total mass, prepare generation, dry and grind to 200 Reserved. See Table 3 for the mass added to 1L of industrial wastewater with a heavy metal ion content of 1g / L to achieve 90% removal of heavy metals.

[0025]

[0026] Through above-mentioned embodiment, compared with conventional inorganic flocculant and organic flocculant, all have obvious advantages in the removal of heavy metal ion to sample waste water, the removal of suspended matter in water; Compared with pure pregelatinized starch, chitosan flocculant and Compared with PAM, the copolymer flocculant makes their respective functions better coordinated, and effectively removes common heavy metals in sample wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com