Method for preparing glycine betaine by using beet ethyl alcohol waste liquor

A technology of alcohol waste liquid and betaine, which is applied in chemical instruments and methods, preparation of cyanide reaction, preparation of organic compounds, etc. It can solve problems affecting high-value applications, unguaranteed output, unstable product quality, etc. , to achieve significant economic and social benefits, good environmental protection effects, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

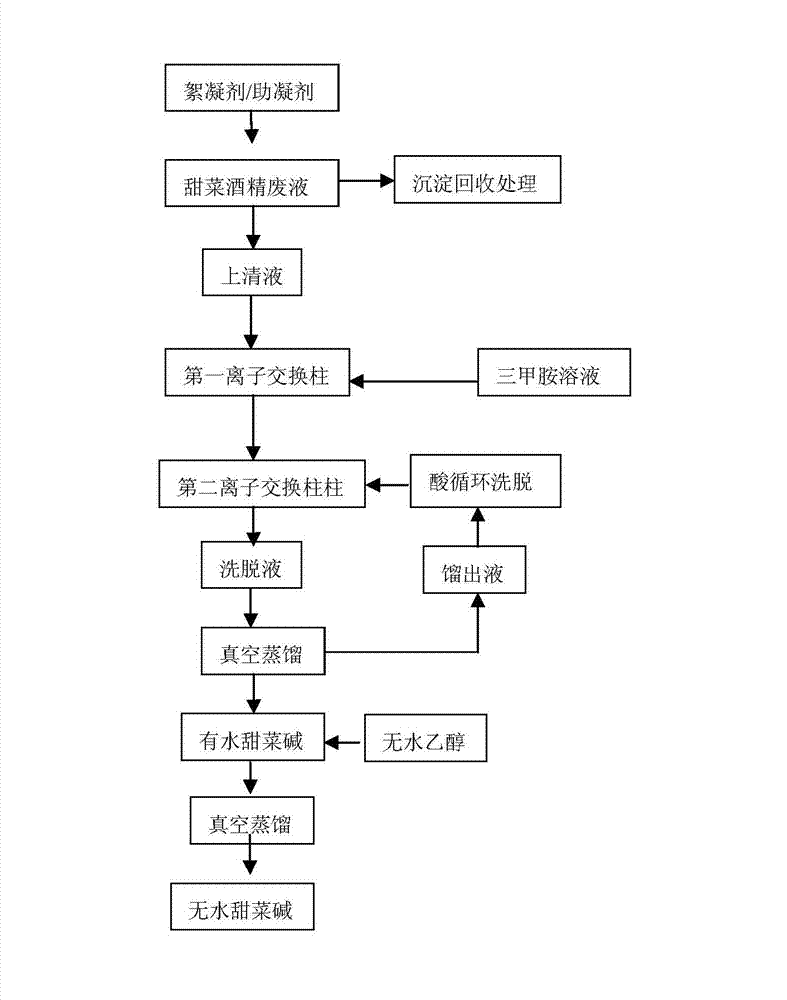

[0028] Such as figure 1 Shown, the method for preparing betaine with beet alcohol waste liquor of the present embodiment may further comprise the steps:

[0029] (1) Add the flocculant polyacrylamide and coagulant aid to the beet alcohol waste liquid to form a mixture. The beet alcohol waste liquid is left at a temperature of 30°C for 2 hours to flocculate and settle the suspended matter, and take the supernatant; The add-on of described flocculant is: every 100ml sugar beet alcohol waste liquor adds 1g flocculant; Described coagulant aid is made up of the calcium oxide that is 40% by volume percentage and the phosphoric acid of 60% by volume percentage; The addition of described coagulant aid The amount is: add 1g of coagulant for every 100ml of beet alcohol waste liquid;

[0030] (2) The supernatant obtained in step (1) is decolorized, desalted and impurity-removed through the first ion-exchange column equipped with a mixed resin; Mixed with a volume ratio of 1;

[0031] ...

Embodiment 2

[0037] The method for preparing betaine with beet alcohol waste liquor of the present embodiment may further comprise the steps:

[0038](1) Add flocculant polyacrylamide and coagulant aid to the beet alcohol waste liquid to form a mixture, put the beet alcohol waste liquid at a temperature of 100°C for 24 hours to flocculate and settle the suspended matter, and take the supernatant; The addition amount of described flocculant is: every 100ml sugar beet alcohol waste liquid adds 10g flocculant; Step (1) described coagulant is made up of the calcium oxide that volume percentage is 90% and the phosphoric acid that volume percentage is 10%; The amount of coagulant added is: add 10g of coagulant per 100ml beet alcohol waste liquid;

[0039] (2) The supernatant obtained in step (1) is decolorized, desalted and impurity-removed through the first ion-exchange column equipped with a mixed resin; Mixed with a volume ratio of 15;

[0040] (3) Adjust the pH value of the supernatant tre...

Embodiment 3

[0046] The method for preparing betaine with beet alcohol waste liquor of the present embodiment may further comprise the steps:

[0047] (1) Add the flocculant polyacrylamide and coagulant aid to the beet alcohol waste liquid to form a mixture. The beet alcohol waste liquid is allowed to stand at a temperature of 70°C for 10 hours, and the temperature is 70°C to flocculate and settle the suspended matter. clear liquid; the addition of the flocculant is: every 100ml beet alcohol waste liquid adds 5g flocculant; the coagulant aid in step (1) is composed of calcium oxide with a volume percentage of 70% and phosphoric acid with a volume percentage of 30% ; The addition of the coagulant aid is: every 100ml beet alcohol waste liquid adds 5g coagulant aid;

[0048] (2) The supernatant obtained in step (1) is decolorized, desalted and impurity-removed through the first ion exchange column equipped with mixed resin; Mixed with a volume ratio of 8;

[0049] (3) Use a trimethylamine s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com