Mesoporous molecular sieve SBA-15 composite nano surface imprinted polymer and preparation method thereof

A mesoporous molecular sieve and surface imprinting technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as deficiencies, and achieve the effects of large pore size, low preparation cost, and uniform pore diameter distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

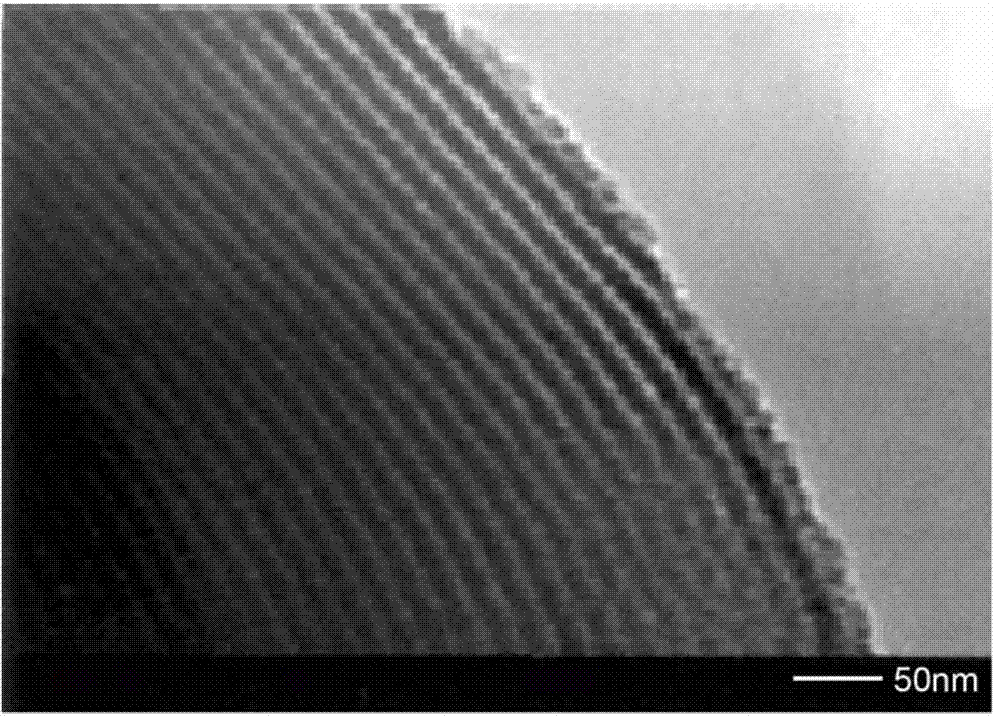

[0034](1).Add 2g (polyoxyethylene-polyoxypropylene-polyoxyethylene, PEO-PPO-PEO) triblock copolymer (referred to as P123) to 60g 2M hydrochloric acid and 15g deionized water at 40°C, stir and dissolve for 4 hours, The rotating speed is 500rpm; add 4.25g tetraethyl orthosilicate while stirring, continue to stir for 24h at 40°C, and the rotating speed is 1000rpm; let it stand in a polytetrafluoroethylene autoclave at 100°C for 24h; filter, dry at room temperature, and obtain the product in horse In the Furnace, the temperature was programmed to rise to 550°C at 5°C / min, and then fired at 550°C for 6 hours to obtain SBA-15 powder.

[0035] (2). Weigh 0.5g of the obtained SBA-15 powder and ultrasonically disperse it in 50mL of toluene solution, add 10mL of MPS, blow nitrogen gas for 10min, seal the mixed solution, rotate at 1000rpm, stir and reflux at 55°C for 24h to obtain the modified The finished SBA-15 was then ultrasonically washed with toluene and methanol, centrifuged to re...

Embodiment 2

[0040] (1).Add 2g (polyoxyethylene-polyoxypropylene-polyoxyethylene, PEO-PPO-PEO) triblock copolymer (referred to as P123) to 60g 2M hydrochloric acid and 15g deionized water at 40°C, stir and dissolve for 4 hours, The rotating speed is 500rpm; add 4.25g tetraethyl orthosilicate while stirring, continue to stir for 24h at 40°C, and the rotating speed is 1000rpm; let it stand in a polytetrafluoroethylene autoclave at 100°C for 24h; filter, dry at room temperature, and obtain the product in horse In the Furnace, the temperature was programmed to rise to 550°C at 5°C / min, and then fired at 550°C for 6 hours to obtain SBA-15 powder.

[0041] (2). Weigh 0.5g of the obtained SBA-15 powder and ultrasonically disperse it in 50mL of toluene solution, add 15mL of MPS, blow nitrogen gas for 10min, seal the mixed solution, rotate at 1000rpm, stir and reflux at 55°C for 24h to obtain the modified The finished SBA-15 was then ultrasonically washed with toluene and methanol, centrifuged to r...

Embodiment 3

[0046] (1).Add 2g (polyoxyethylene-polyoxypropylene-polyoxyethylene, PEO-PPO-PEO) triblock copolymer (referred to as P123) to 60g 2M hydrochloric acid and 15g deionized water at 40°C, stir and dissolve for 4 hours, The rotating speed is 500rpm; add 4.25g tetraethyl orthosilicate while stirring, continue to stir for 24h at 40°C, and the rotating speed is 1000rpm; let it stand in a polytetrafluoroethylene autoclave at 100°C for 24h; filter, dry at room temperature, and obtain the product in horse In the Furnace, the temperature was programmed to rise to 550°C at 5°C / min, and then fired at 550°C for 6 hours to obtain SBA-15 powder.

[0047] (2). Weigh 0.5g of the obtained SBA-15 powder and ultrasonically disperse it in 100mL of toluene solution, add 20mL of MPS, blow nitrogen gas for 10min, seal the mixture, rotate at 1000rpm, stir and reflux at 55°C for 24h to obtain the modified The finished SBA-15 was then ultrasonically washed with toluene and methanol, centrifuged to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com