Dual-component epoxy resin adhesive for splicing silicon block or silicon rod and preparation method of dual-component epoxy resin adhesive

A technology of epoxy resin glue and epoxy resin, which is applied in the directions of epoxy resin glue, novolak epoxy resin adhesive and adhesive, can solve the problems of long curing time at room temperature and obvious accumulation of objects to be treated, etc. To achieve the effect of shortening the initial curing time, meeting process requirements, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the two-component epoxy resin glue that is used for silicon block or silicon rod splicing comprises the steps:

[0025] The preparation process of component A is as follows: put epoxy resin, phenolic modified epoxy resin, thixotropic agent, and filler into the reaction kettle, and stir in vacuum for 1.5 to 3 hours;

[0026] The preparation process of component B is as follows: Put the modified amine curing agent, polymer mercaptan, accelerator, thixotropic agent, and filler into the reaction kettle, and stir in vacuum for 1.5 to 3 hours.

Embodiment 1

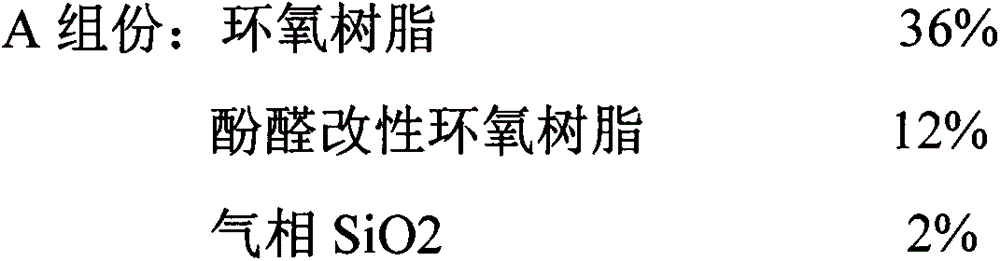

[0028]

[0029]

[0030] Preparation of component A: Put epoxy resin, phenolic modified epoxy resin, gas phase SiO2, and silicon micropowder into the reaction kettle according to mass percentage, and stir in vacuum for 1.5 hours.

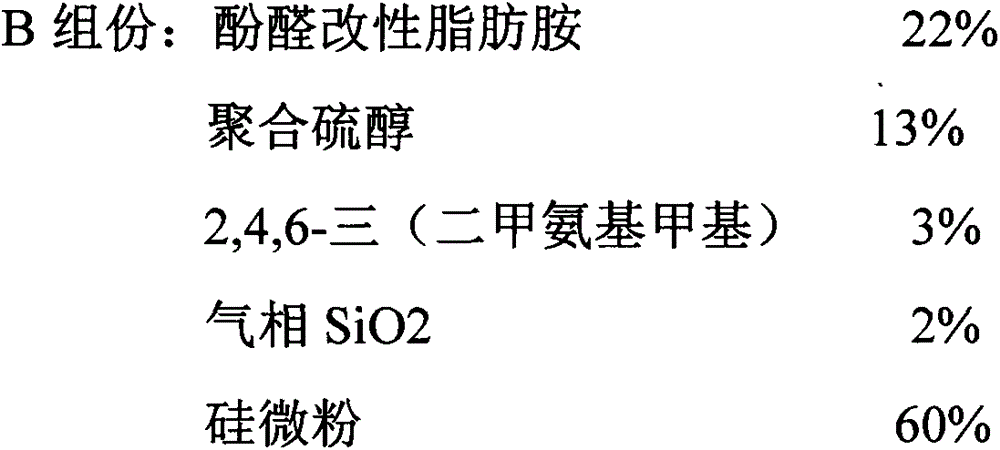

[0031]

[0032] Preparation of component B: Put phenolic modified fatty amine, polymeric mercaptan, 2,4,6-tris(dimethylaminomethyl), gas phase SiO2, and silicon micropowder into the reaction kettle according to mass percentage, and stir in vacuum for 1.5 hours.

Embodiment 2

[0034]

[0035] The preparation process of component A is as follows: Put epoxy resin, phenolic modified epoxy resin, bentonite, and silicon micropowder into the reaction kettle according to the mass percentage, and stir in vacuum for 3 hours.

[0036]

[0037] The preparation process of component B is as follows: put phenolic modified fatty amine, polymerized mercaptan, 2,4,6-tris(dimethylaminomethyl), gas phase SiO2, silicon micropowder into the reaction kettle according to the mass percentage, and vacuum stir for 3 Hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com