Cefotaxime sodium composition freeze-dried powder for injection

A technology of cefotaxime sodium and freeze-dried powder injection, which is applied in the field of medicine and medicine manufacturing, and can solve problems such as failure of clinical treatment plans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

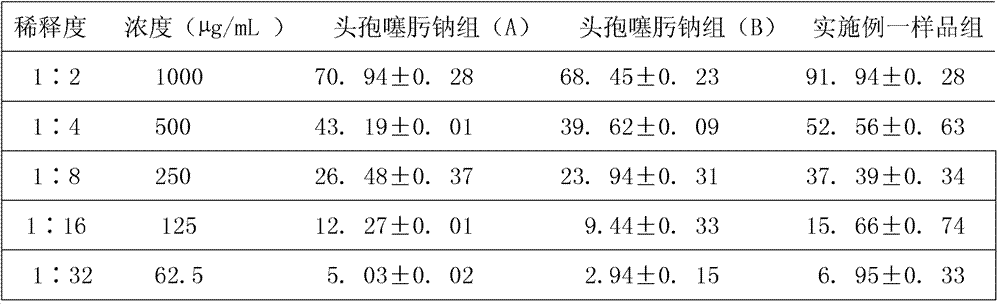

Examples

Embodiment 1

[0026] Embodiment 1, preparation of cefotaxime sodium composition freeze-dried powder for injection, in 1000 pieces.

[0027] Prescription:

[0028] Cefotaxime Sodium 1000g

[0029] Chitosan Nanoparticles 800g

[0030] Water for injection 2000ml

[0031] 2. Preparation process:

[0032] The chitosan nanoparticle that weighs 800g is slowly added in the water for injection of 2000ml, stirs while adding, until dissolving.

[0033] Add 1000 g of cefotaxime sodium and stir to dissolve until clear.

[0034] Adjust the pH to 5.1 with buffer salts of sodium dihydrogen phosphate and disodium hydrogen phosphate, add 0.1% activated carbon and stir for 30 minutes, filter out the activated carbon, filter the liquid through 0.45 μm and 0.22 μm microporous membranes, and detect the content of intermediates , according to 1.0g per bottle of cefotaxime sodium to calculate the filling volume.

[0035] Fill according to the test requirements, put it into a freeze dryer after half-tamping, ...

Embodiment 2

[0036] Embodiment 2, preparation of cefotaxime sodium composition freeze-dried powder for injection, in 1000 pieces.

[0037] 1. Prescription:

[0038] Cefotaxime Sodium 1000g

[0039] Chitosan Nanoparticles 865g

[0040] Water for injection 2000ml

[0041] 2. Preparation process:

[0042] The chitosan nanoparticle that weighs 865g is slowly added in the water for injection of 2000ml, stirs while adding to dissolve.

[0043] Add 1000 g of cefotaxime sodium and stir to dissolve until clear.

[0044] Adjust the pH to 5.1 with buffer salts of sodium dihydrogen phosphate and disodium hydrogen phosphate, add 0.1% activated carbon and stir for 30 minutes, filter out the activated carbon, filter the liquid through 0.45 μm and 0.22 μm microporous membranes, and detect the content of intermediates , according to 1.0g per bottle of cefotaxime sodium to calculate the filling volume.

[0045] Fill according to the test requirements, put it into a freeze dryer after half-tamping, coo...

Embodiment 3

[0046] Embodiment 3, preparation of cefotaxime sodium composition freeze-dried powder for injection, in 1000 pieces.

[0047] Prescription:

[0048] Cefotaxime Sodium 1000g

[0049] Chitosan Nanoparticles 757g

[0050] Water for injection 2000ml

[0051] 2. Preparation process:

[0052] The chitosan nanoparticle that takes by weighing 757g is slowly added in the water for injection of 2000ml, stirs while adding to dissolving.

[0053] Add 1000 g of cefotaxime sodium and stir to dissolve until clear.

[0054] Adjust the pH to 5.1 with buffer salts of sodium dihydrogen phosphate and disodium hydrogen phosphate, add 0.1% activated carbon and stir for 30 minutes, filter out the activated carbon, filter the liquid through 0.45 μm and 0.22 μm microporous membranes, and detect the content of intermediates , according to 1.0g per bottle of cefotaxime sodium to calculate the filling volume.

[0055] Fill according to the test requirements, put it into a freeze dryer after half-ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com