High-performance polycarboxylic acid water reducer and special compound admixture containing the water reducer for limestone powder concrete

A technology with limestone powder and high performance, which is applied in the field of special composite admixtures for limestone powder concrete, which can solve problems such as unfavorable engineering construction, bleeding, and increased dosage of concrete admixtures, so as to achieve good workability of concrete and improve water retention performance , the effect of excellent sustained release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

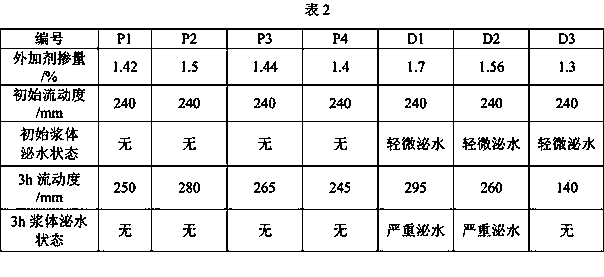

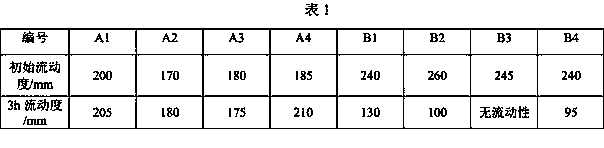

Examples

Embodiment 1

[0032] (1) Component c maleic anhydride glycol ester, the preparation method is: under inert atmosphere, put ethylene glycol into 1# reactor, heat up to 30°C, and then put maleic anhydride solid into 1# In the reaction kettle, stir for 3 hours to obtain the esterified maleic anhydride glycol ester, labeled as c1. Wherein, the molar ratio of maleic anhydride and ethylene glycol is 2.5:1.

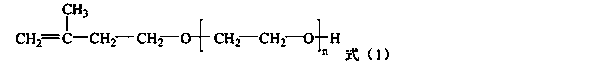

[0033] (2) Polycarboxylate high-performance water reducer I, the preparation method of which is:

[0034] According to the mass percentage of monomer a isopentenyl polyoxyethylene ether, monomer b methyl acrylate and maleic anhydride diol ester c1 is 71wt%, 10wt%, 29wt; the preparation of ammonium persulfate (initiator) Amount by weight is 0.2% of the total weight of reaction monomer a, b and c1; The amount of stock preparation of mercaptoacetic acid (chain transfer agent) is by weight 0.1% of the total weight of monomer a, b and component c1;

[0035] Maleic anhydride dihydric alcohol...

Embodiment 2

[0041] (1) Component c maleic anhydride glycol ester, its preparation method is: under inert atmosphere, put butanediol into 1# reactor, heat up to 45°C, and then put maleic anhydride solid into 1# In the reaction kettle, stir for 2 hours to obtain the esterified maleic anhydride glycol ester, labeled as c2. Wherein, the molar ratio of maleic anhydride and ethylene glycol is 2.5:1.

[0042] (2) Polycarboxylate high-performance water reducer I, the preparation method of which is:

[0043] According to the mass percent of monomer a isopentenyl polyoxyethylene ether, monomer b methyl acrylate and maleic anhydride glycol ester c2 is 80wt%, 1wt%, 19wt to prepare materials;

[0044] Maleic anhydride glycol ester c2 is made into an aqueous solution, and the mass concentration is 50%;

[0045] The stock quantity of ammonium persulfate (initiator) is by weight 0.5% of the total weight of reaction monomer a, b and c2;

[0046] The stock quantity of mercaptoacetic acid (chain transfer...

Embodiment 3

[0051] (1) Component c maleic anhydride diol ester, its preparation method is: under inert atmosphere, put octane glycol into 1# reaction kettle, heat up to 60°C, and then put maleic anhydride solid into 1# In the reaction kettle, stir for 1 h to obtain the esterified maleic anhydride glycol ester, labeled as c3. Wherein, the molar ratio of maleic anhydride and ethylene glycol is 2.5:1.

[0052] (2) Polycarboxylate high-performance water reducer I, the preparation method of which is:

[0053] According to the mass percent of monomer a isopentenyl polyoxyethylene ether, monomer b methyl acrylate and maleic anhydride glycol ester c3, it is 90wt%, 5wt%, 5wt% to prepare materials;

[0054] Maleic anhydride dihydric alcohol ester c1 is formulated into an aqueous solution with a mass concentration of 50%;

[0055] The stock quantity of ammonium persulfate (initiator) is by weight 0.3% of the gross weight of reaction monomer a, b and c3;

[0056] The stock quantity of mercaptoacet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com