Cuprous complex luminescence material and preparation method thereof

A technology of luminescent materials and complexes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

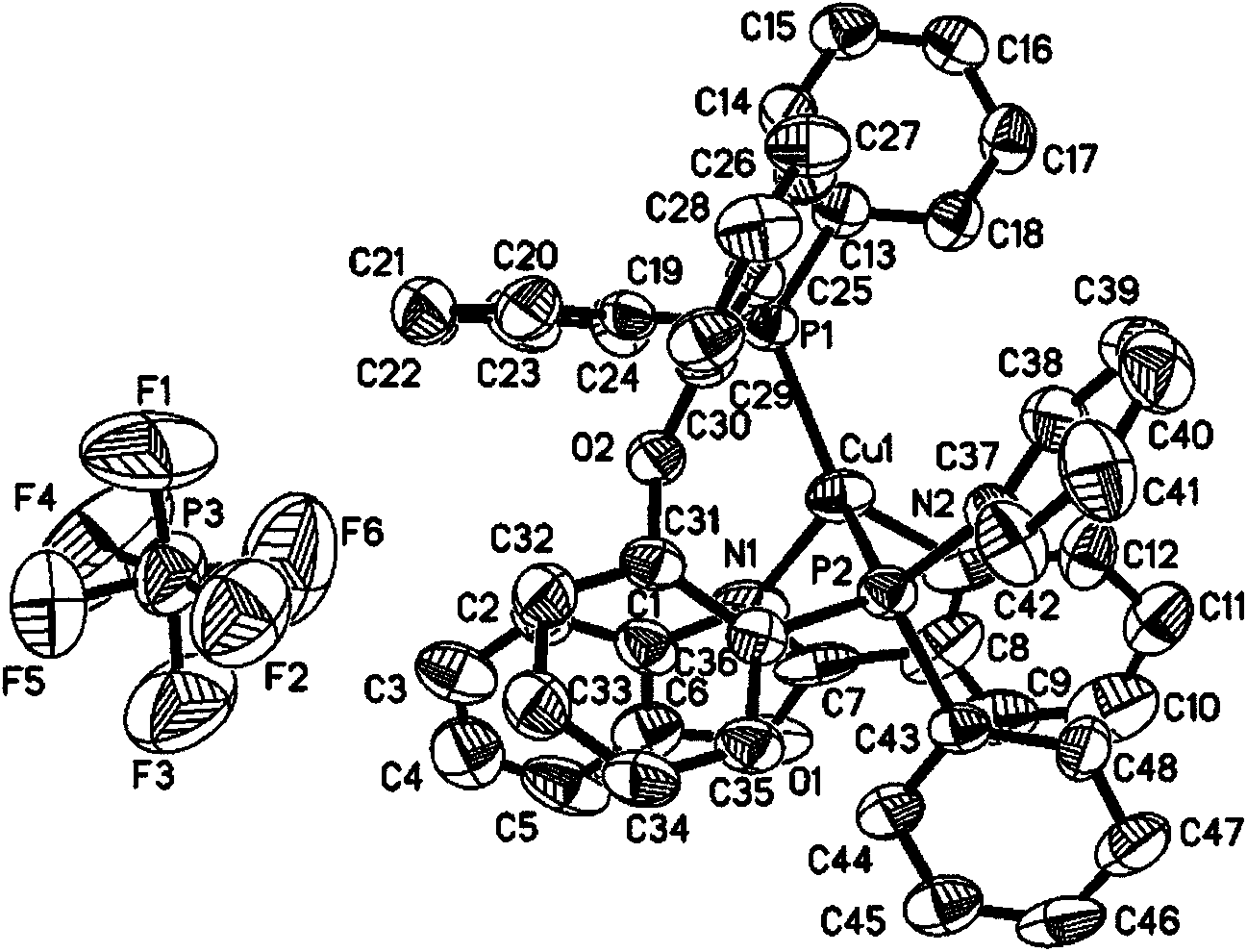

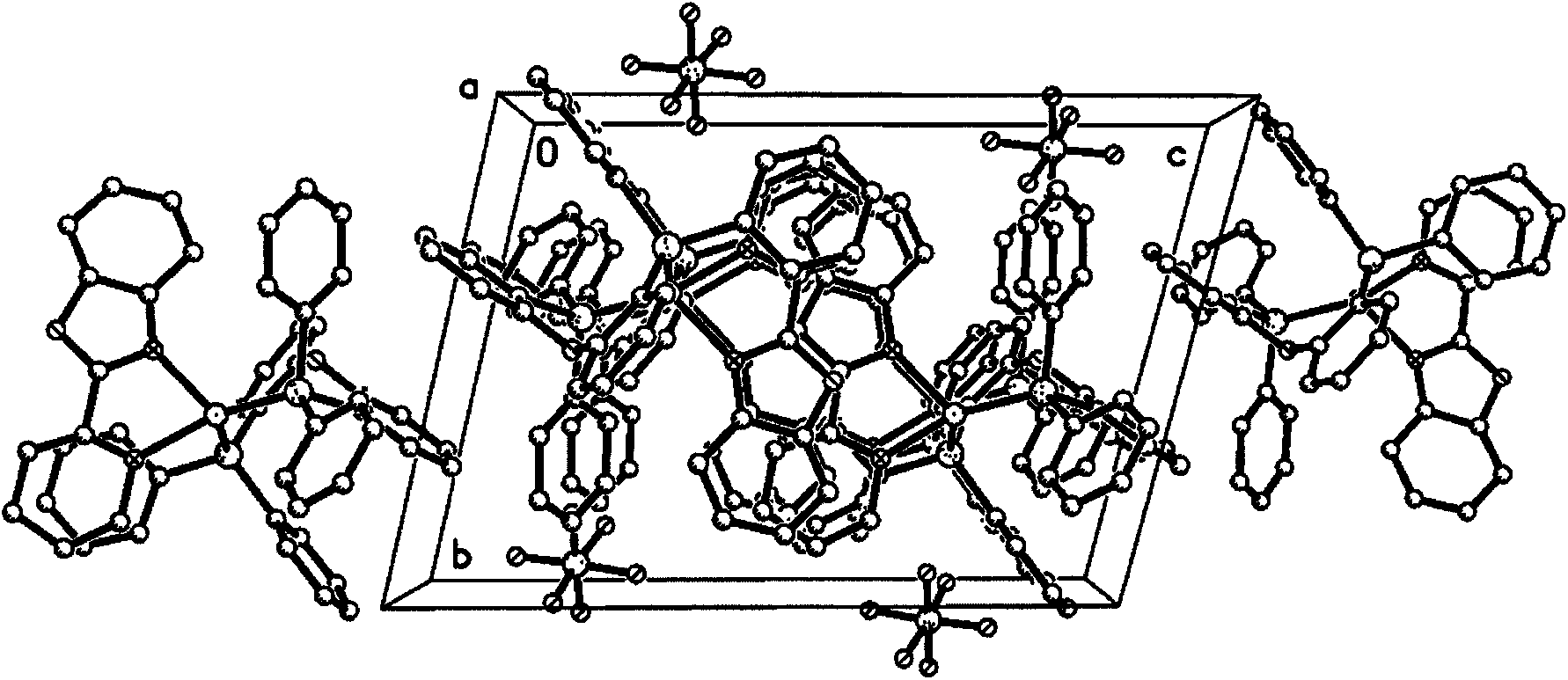

[0031] Synthesis of Cu(I) Complex Cu(2-PBO)(POP)(PF 6) single crystal: weigh 37mg Cu(CH 3 EN) 4 PF 6 and 54mg of POP ligand were dissolved in 5mL of dichloromethane, then 20mg of 2-PBO ligand was added to the above solution at one time, stirred to dissolve it completely and then filtered, and the filtrate was covered with isopropanol to promote crystallization of the product, and stood for several A large number of yellow flaky crystals were precipitated after days. A yellow crystal with a size of 0.29mm×0.18mm×0.01mm was selected for X-ray single crystal structure test. The molecular structure of the compound is shown in the attached figure 1 , and its unit cell packing structure is shown in the attached figure 2 .

Embodiment 2

[0033] Preparation of a large number of microcrystalline samples: weigh 112mg Cu(CH 3 EN) 4 PF 6 Dissolve in 20mL of acetonitrile, weigh 162mg of POP and 59mg of 2-PBO ligand and dissolve in 20mL of acetonitrile (the molar ratio of the three reactants is 1:1:1), these two acetonitrile solutions are mixed, and stirring to make the coordination reaction fully occur, and finally the resulting yellow solution was filtered, and all solvents were removed by rotary evaporation, and vacuum-dried to obtain a yellow crystal powder as the product with a yield of 98% (calculated as Cu).

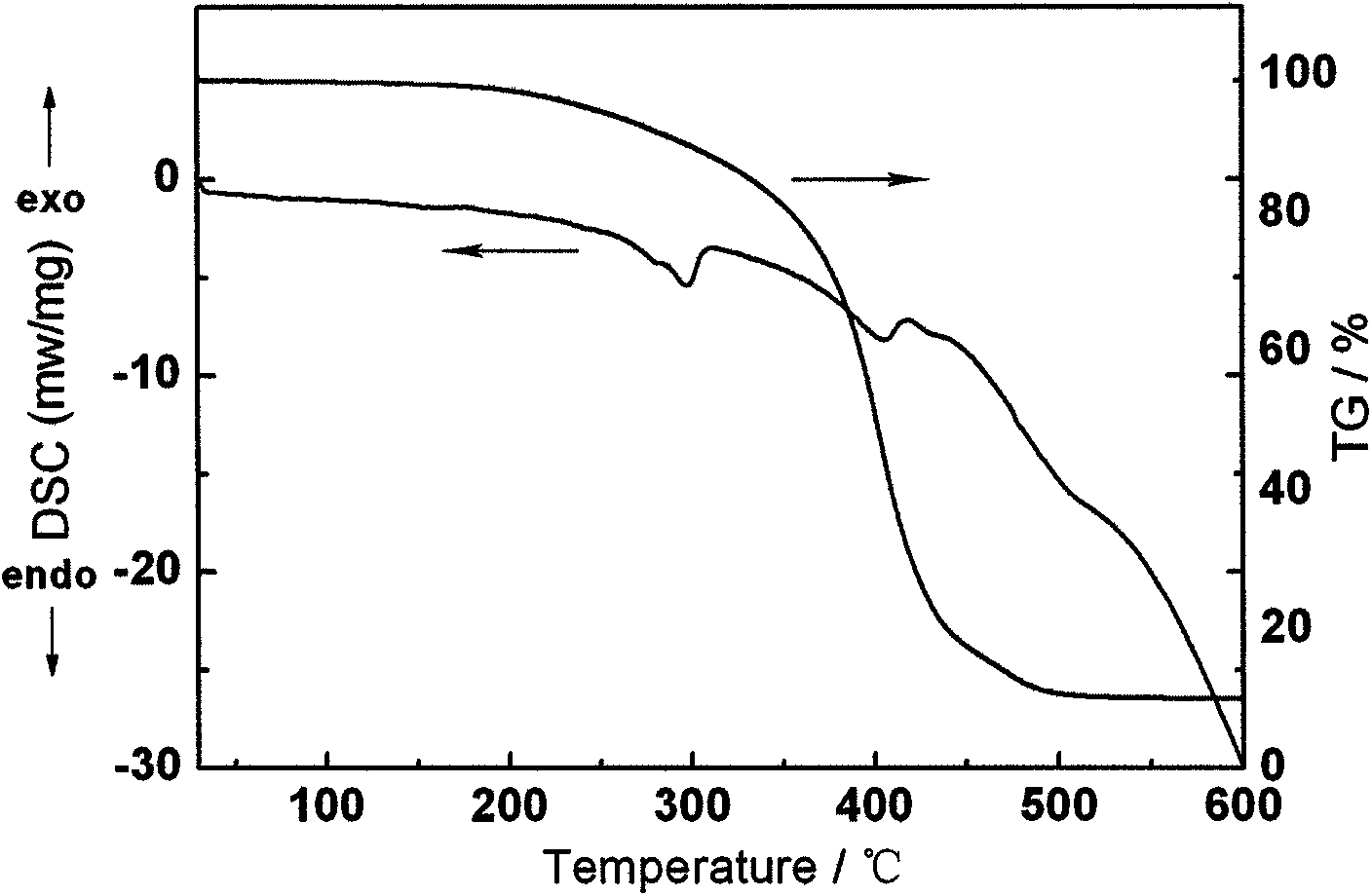

[0034] For the complex Cu(2-PBO)(POP)(PF 6 ) of pure-phase crystal samples were tested for a series of properties. Microscopic melting point tests showed a melting point of 190°C. TG and DSC tests show that the material has good thermal stability, its initial decomposition temperature reaches 270 degrees Celsius, and there is no other obvious thermal transition before its melting point, see attached ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com