Motherboard coated with conformal coating

A technology for conformal paint and motherboard, applied in coatings, polyurea/polyurethane coatings, instruments, etc., can solve the problems of water resistance, oil resistance and poor self-cleaning performance of the coating film, and achieve good self-cleaning and anti-fouling. Effect, good oil resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

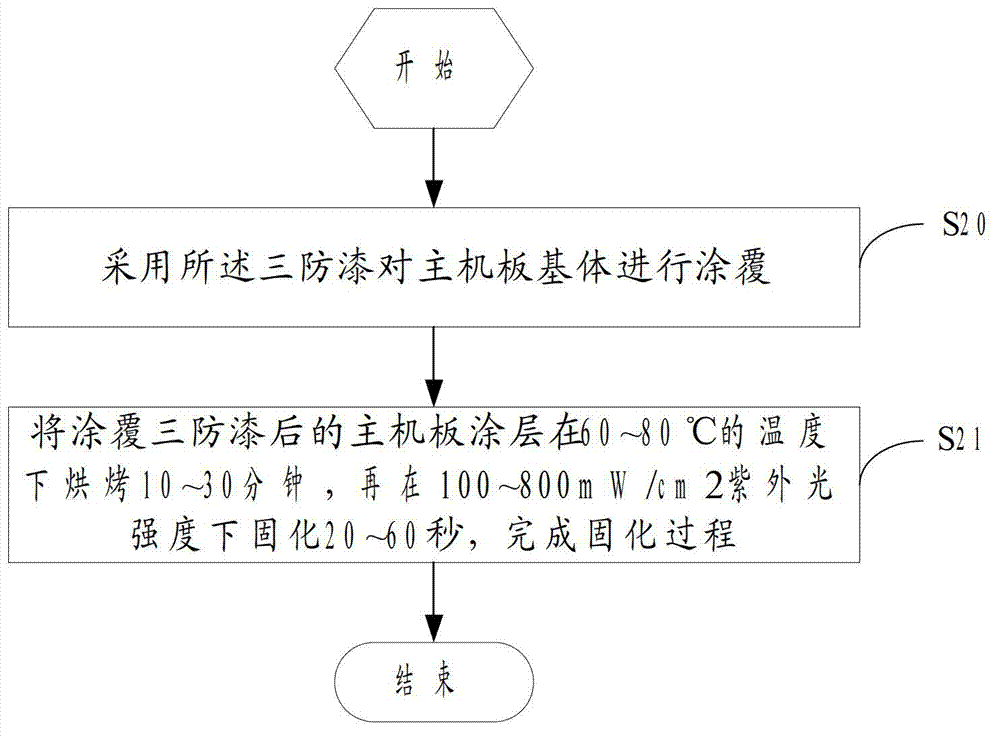

Method used

Image

Examples

Embodiment 1

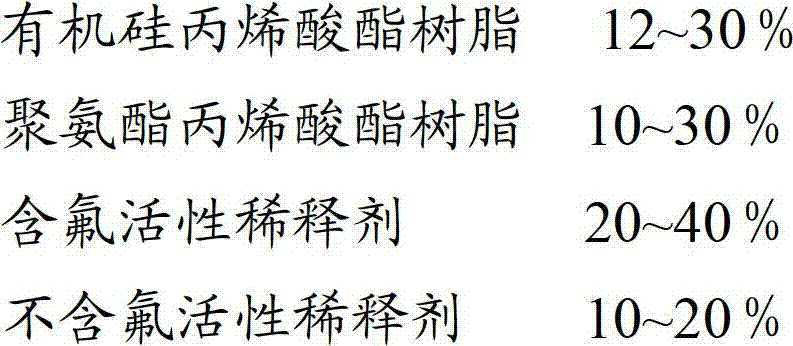

[0036] The conformal paint in this embodiment includes the following components calculated by mass percentage:

[0037]

[0038]

[0039] Above-mentioned polyurethane acrylate resin can adopt following method to prepare:

[0040] Add 700g of polyester polyol XH-6480 (such as produced by Nanyang Xianhe New Material Co., Ltd.) into the reaction bottle, after heating at 100°C and vacuuming for 1 hour, add diisocyanate TDI, dissolve and mix evenly, and react for 3 hours. The molar ratio scope of the hydroxyl group in the ester polyol and the isocyanate group in the diisocyanate is 0.5: 1; Then in the product, add 5wt% hydroxyethyl methacrylate (HEMA ), cooled to 75°C for 1 hour, added 5wt% initiator azobisisobutyronitrile relative to the mass of hydroxyethyl methacrylate, reacted for 6 hours at 75°C, cooled, cooled to 50°C and then added relative React with hydroxyethyl methacrylate (HEMA) with a molar weight of 5% diisocyanate for 0.5 hours and then cool to obtain a polyur...

Embodiment 2

[0045] This embodiment provides a kind of anti-corrosion paint for mainboard protection, which includes the following components calculated by mass percentage:

[0046]

[0047] Above-mentioned polyurethane acrylate resin can adopt following method to prepare:

[0048] Add 500g of polyester polyol XH-8350 (such as produced by Nanyang Xianhe New Material Co., Ltd.) into the reaction bottle. After heating at 120°C and vacuuming for 1 hour, add diisocyanate MDI, dissolve and mix evenly, and react for 5 hours. The molar ratio range of the hydroxyl group in the ester polyol to the isocyanate group in the diisocyanate is 0.8:1; then add 10wt% hydroxyethyl methacrylate (HEMA ), lower the temperature to 85°C for 2 hours, add 5wt% initiator azobisisobutyronitrile relative to the mass of hydroxyethyl methacrylate, react at 85°C for 10 hours, cool down, and then add relative React with hydroxyethyl methacrylate (HEMA) with a molar weight of 5% diisocyanate for 2 hours and then cool t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com