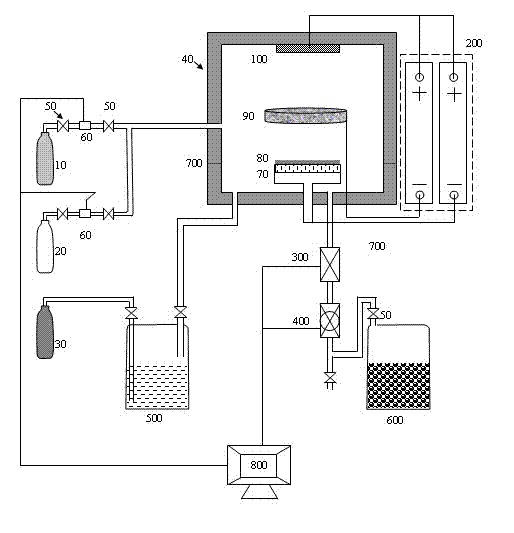

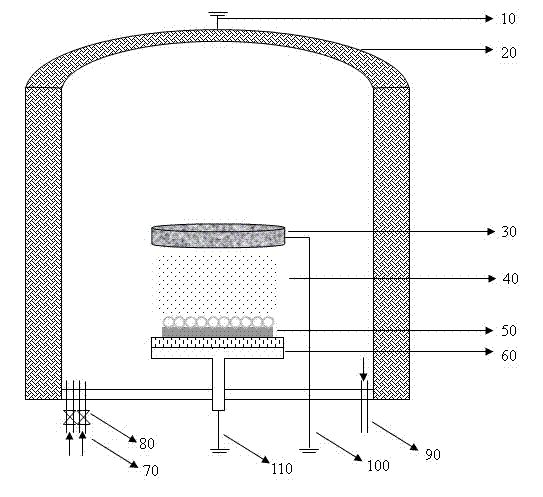

Plasma physical and chemical codeposition apparatus and deposition method thereof

A chemical co-deposition and plasma technology, which is applied in the field of ion physics and chemical co-deposition devices, can solve the problems of expensive physical vapor deposition sputtering devices, etc., and achieve the effects of low device cost, simple deposition process operation, and fast deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Using graphite carbon as the workpiece and high-purity molybdenum disk as the target, the vacuum system is turned on to make the furnace in a vacuum state. Open the argon gas cylinder, feed argon gas into the furnace, and the computer system controls the flow, and cleans the surface of the workpiece for half an hour. Slowly open the hydrogen cylinder, pass it into the silane liquid inner tank, and reheat it to a certain temperature, and the computer system controls its flow. The silane flow into the vacuum deposition chamber is 10 sccm, the argon flow is 40 sccm, the working pressure in the vacuum chamber is 5Pa, the target voltage is -800V, and the workpiece voltage is -300V. After 1 h of deposition, a molybdenum-silicon carbide composite film with a thickness of about 4 μm can be obtained. The molybdenum-silicon carbide composite film sample and the molybdenum silicide coating sample were subjected to high-temperature oxidation tests. After high-temperature oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com