Method for testing tin content of tin-lead solder through flame atomic absorption spectroscopy method

A technology of flame atomic absorption and tin-lead solder, which is applied in the field of chemical analysis, can solve the problems of high operational proficiency, complex test process, and large amount of reagents, and achieve simple operation, less acid consumption, and high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: the pretreatment method of sample:

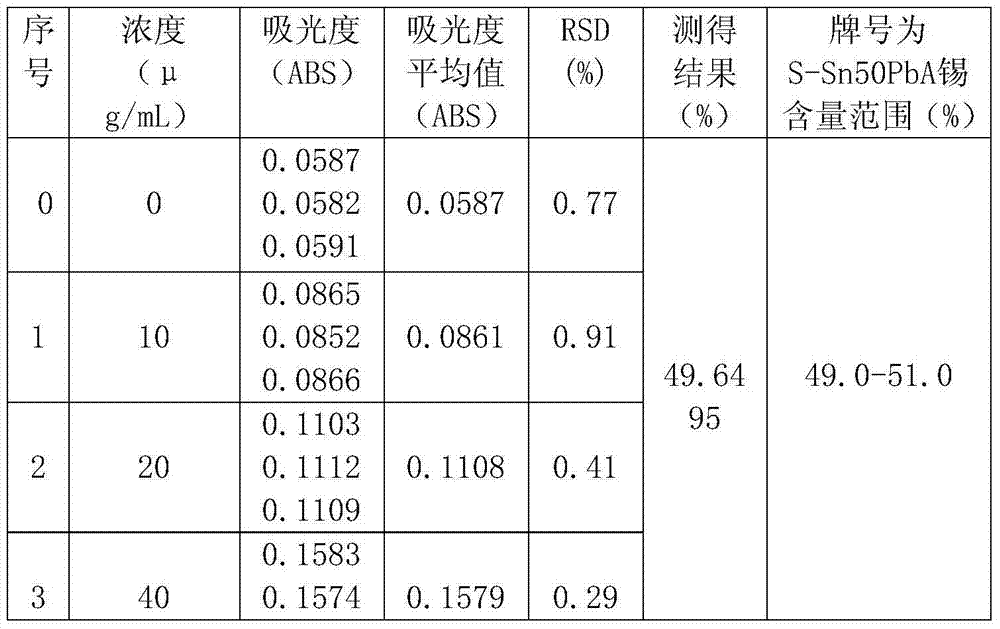

[0015] 1. Take the middle part of tin-lead solder with the brand name S-Sn50PbA, cut it into 0.5cm section with medical scissors, and weigh 0.4850g accurately;

[0016] 2. Put the weighed sample into a 250mL polytetrafluoro beaker, add 1mL nitric acid, 2mL hydrofluoric acid, 1mL hydrogen peroxide, place it on the electric heating plate and heat it to a slight boil at a low temperature. After the sample is completely dissolved, turn off the electric heating plate , use the residual heat of the electric heating plate to drive away the acid, stop the acid drive when the remaining 1ml of the digestion solution is left, cool to room temperature, transfer to a 50mL polyethylene volumetric flask, rinse the Teflon beaker with deionized water, and merge the rinse solution into the volumetric flask, Constant volume; use the same treatment method to make sample blank.

Embodiment 2

[0017] Embodiment 2: concrete experimental test of the present invention:

[0018] 1.1 Instruments and equipment

[0019] WYS2200 atomic absorption spectrometer (Anhui Wanyi Technology), adjustable electric heating plate, WY802-II ultrapure water machine (Anhui Wanyi Technology), tin hollow cathode lamp (Beijing General Institute of Nonferrous Metals)

[0020] 1.2 Reagents and solutions

[0021] (1) Nitric acid: superior grade, 68%, Sinopharm reagent; (2) Hydrofluoric acid: superior grade, Sinopharm reagent; (3) Hydrogen peroxide, superior grade, 30%, Sinopharm reagent; (4) High purity Ionized water, resistivity ≥ 18MΩ.cm; (5) Tin standard solution: 1000μg / mL, Beijing General Institute of Nonferrous Metals; (6) Lead-tin alloy reference material GSB04-1330-60A: National Center for Standard Materials; (7) Tin Lead solder standard samples YTR8801 (30), YTR8805 (90): National Center for Standard Materials.

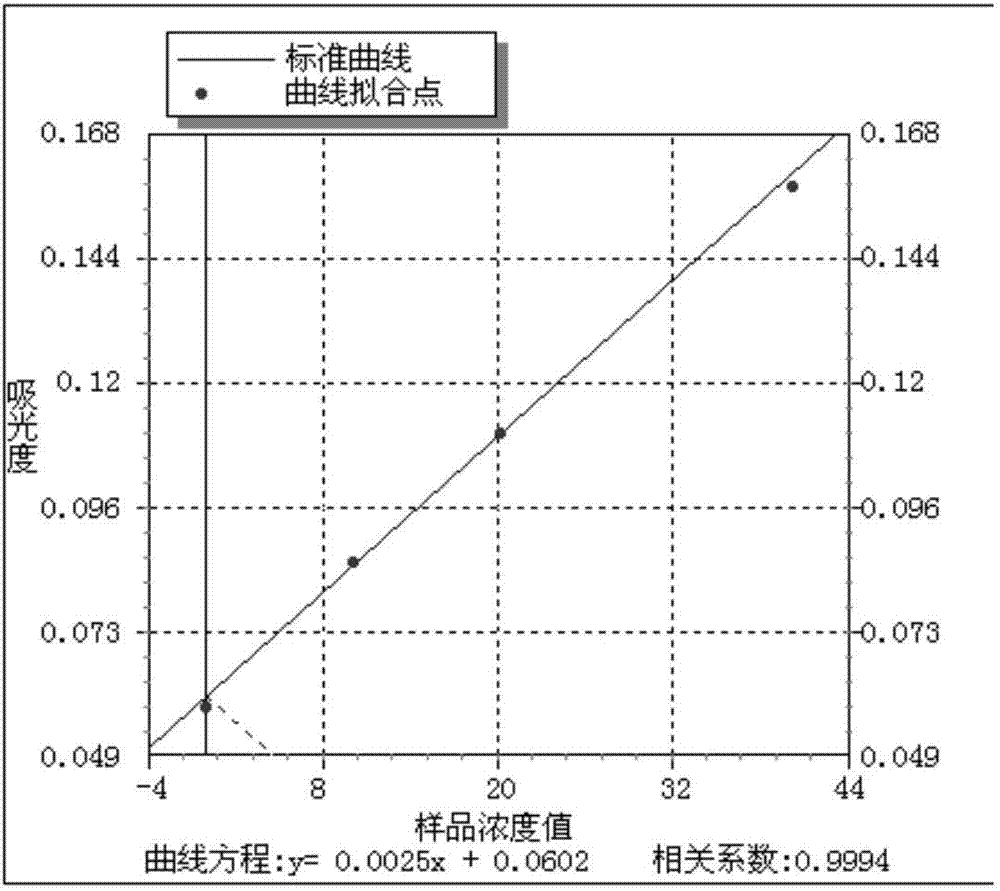

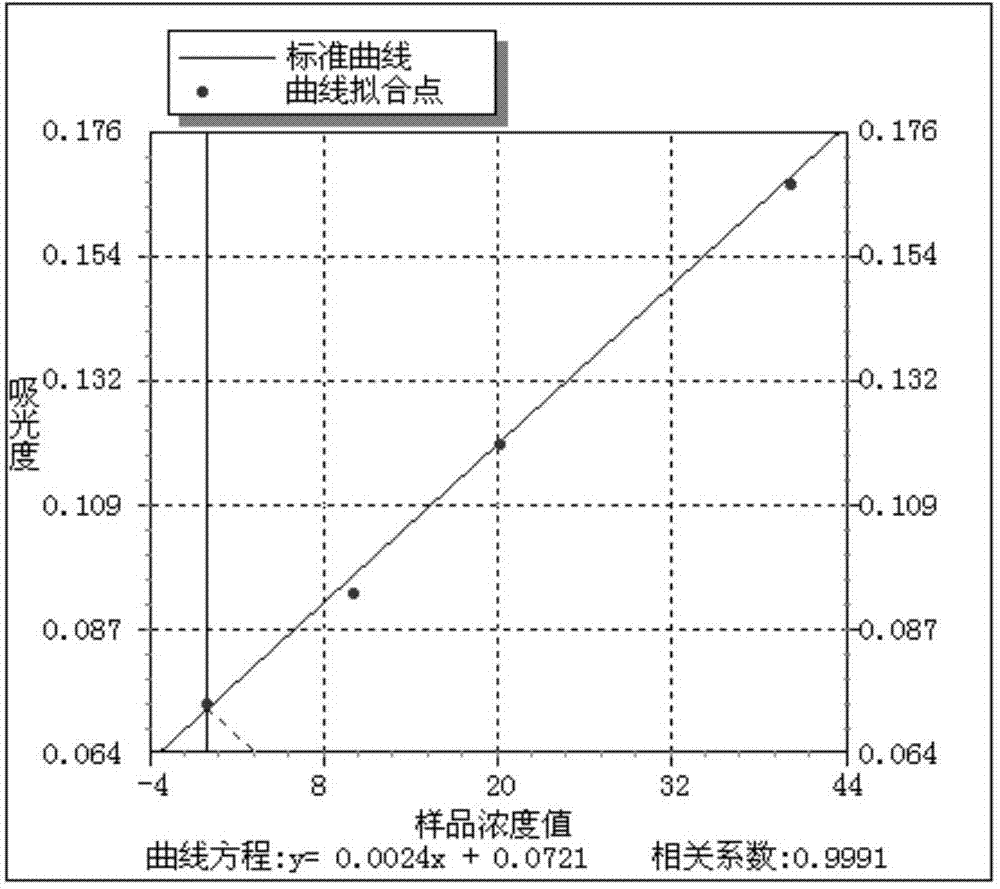

[0022] 1.3 Preparation of standard solution

[0023] Take 4 polyethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com