Titanium dioxide/niobium-titanium oxide composite material as well as preparation and application thereof

A technology of niobium-titanium oxide and titanium dioxide, applied in the field of lithium-ion batteries, can solve the problems of low electronic and lithium-ion conductivity, reduced material volume energy density, etc., and achieve reduced diffusion distance, high packing density, and high batch stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

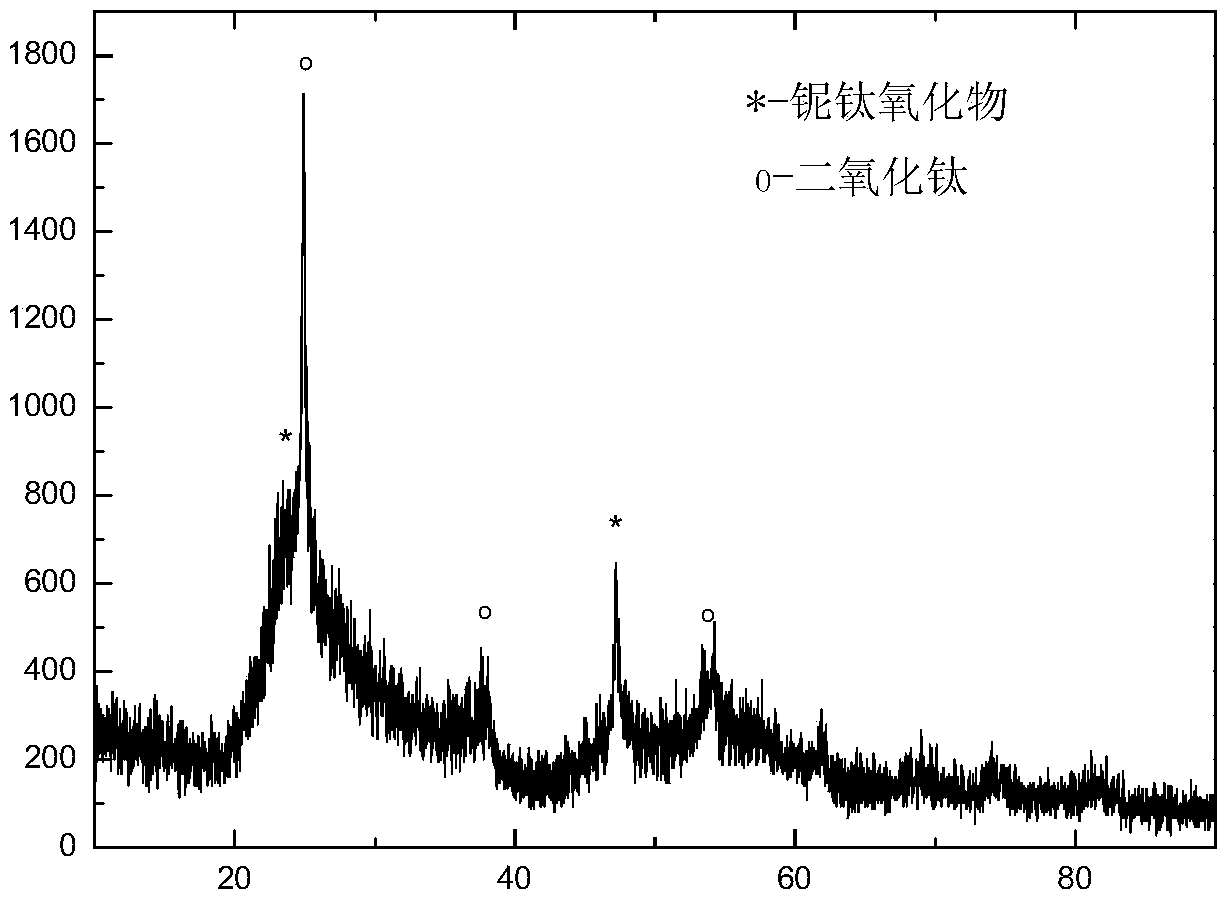

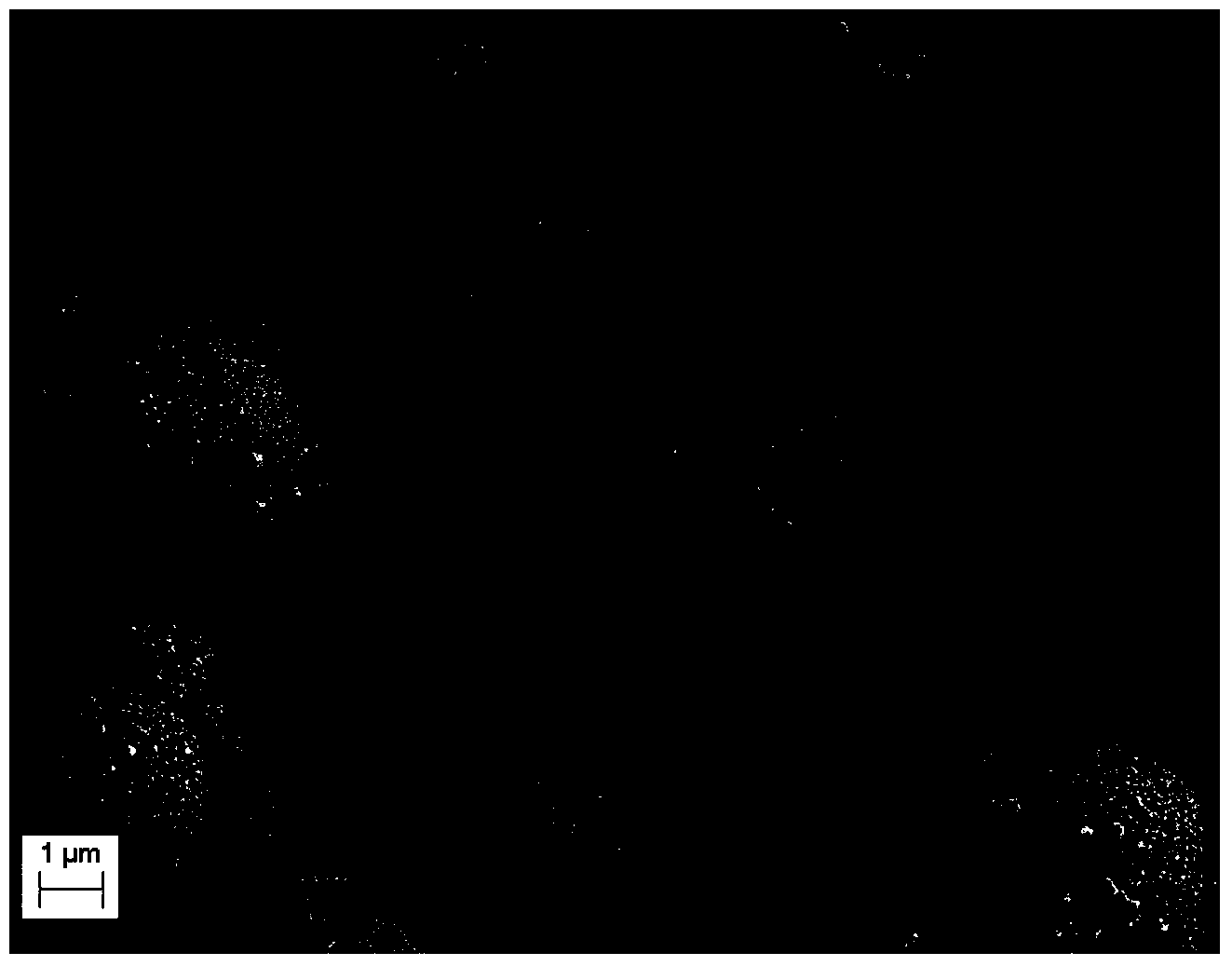

Embodiment 1

[0031]Dissolve 6.8g tetrabutyl titanate in 50ml ethanol solvent to form a clear solution; then add 10.2g niobium chloride to the solution and stir until the solution is clear to obtain a slightly yellow clear solution; then transfer the solution into In a sealable polytetrafluoroethylene reaction kettle, seal the polytetrafluoroethylene container in a stainless steel jacket, put the stainless steel jacket in a heater, raise the temperature to 150°C, and keep it warm for 15 hours. After the reaction was complete, the furnace was cooled to room temperature. The product after the reaction is a mixture of solution and solid phase. The reacted product was filtered and washed 3 times with ethanol to obtain a white solid powder. The titanium dioxide / niobium titanium oxide composite material is obtained after the powder is dried in vacuum at 60°C. The composite material is: anatase-type titanium dioxide particles are dispersed on the surface of a spherical amorphous niobium-titanium...

Embodiment 2

[0034] 3.2g of tetrabutyl titanate was dissolved in 60ml of ethanol solvent to form a clear solution; then 7.1g of niobium chloride was added to the solution and stirred until the solution was clear to obtain a slightly yellow clear solution; then the solution was transferred into In a sealable polytetrafluoroethylene reaction kettle, seal the polytetrafluoroethylene container in a stainless steel jacket, put the stainless steel jacket in a heater, raise the temperature to 170° C., and keep it warm for 8 hours. After the reaction was complete, the furnace was cooled to room temperature. The reacted product is a mixture of solution and solid phase. The reacted product was filtered and washed three times with ethanol repeatedly to obtain a white solid powder. The titanium dioxide / niobium titanium oxide composite material is obtained after the powder is dried in vacuum at 60°C. The composite material is: anatase-type titanium dioxide particles are dispersed on the surface of a ...

Embodiment 3

[0037] Dissolve 3.2g tetrabutyl titanate in 70ml ethanol solvent to form a clear solution; then add 5.5g niobium oxalate to the solution and stir until the solution is clear to obtain a slightly yellow clear solution; In a sealed polytetrafluoroethylene reaction kettle, seal the polytetrafluoroethylene container in a stainless steel jacket, put the stainless steel jacket in a heater, raise the temperature to 190° C., and keep it warm for 12 hours. After the reaction was complete, the furnace was cooled to room temperature. The reacted product is a mixture of solution and solid phase. The reacted product was filtered and washed three times with ethanol repeatedly to obtain a white solid powder. The titanium dioxide / niobium titanium oxide composite material is obtained after the powder is dried in vacuum at 60°C. The composite material is: anatase-type titanium dioxide particles are dispersed on the surface of a spherical amorphous niobium-titanium oxide, and the amorphous nio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com