A kind of preparation method of magnetic mesoporous zirconia composite microsphere

A zirconium dioxide and composite technology, which is applied in the field of magnetic nanocomposite microspheres, can solve the problems of difficult removal of templates, adverse effects of magnetic response performance micro-nanostructures, complicated processes, etc., and achieves stable physical and chemical properties and good application prospects. , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) At room temperature, weigh 0.300g Fe 3 o 4 and 0.300g poly(4-styrene sodium sulfonate), and ultrasonically disperse the two in 100ml deionized water, and ultrasonically disperse for 30min to obtain Fe 3 o 4 Suspension, separated by magnet and washed to obtain polyelectrolyte modified Fe 3 o 4 .

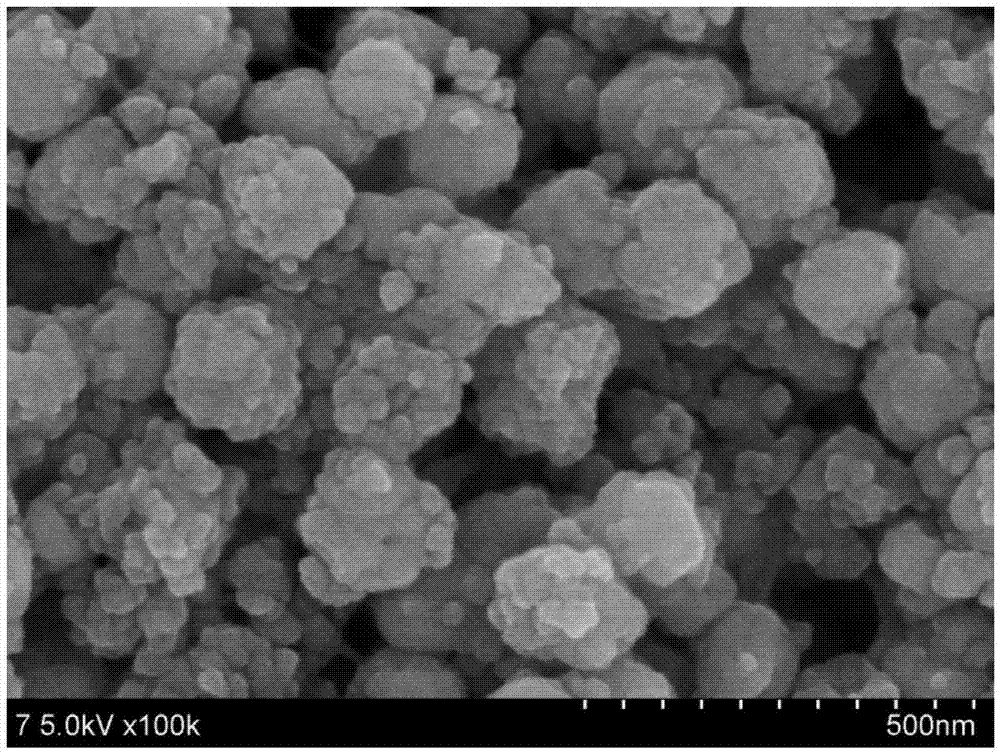

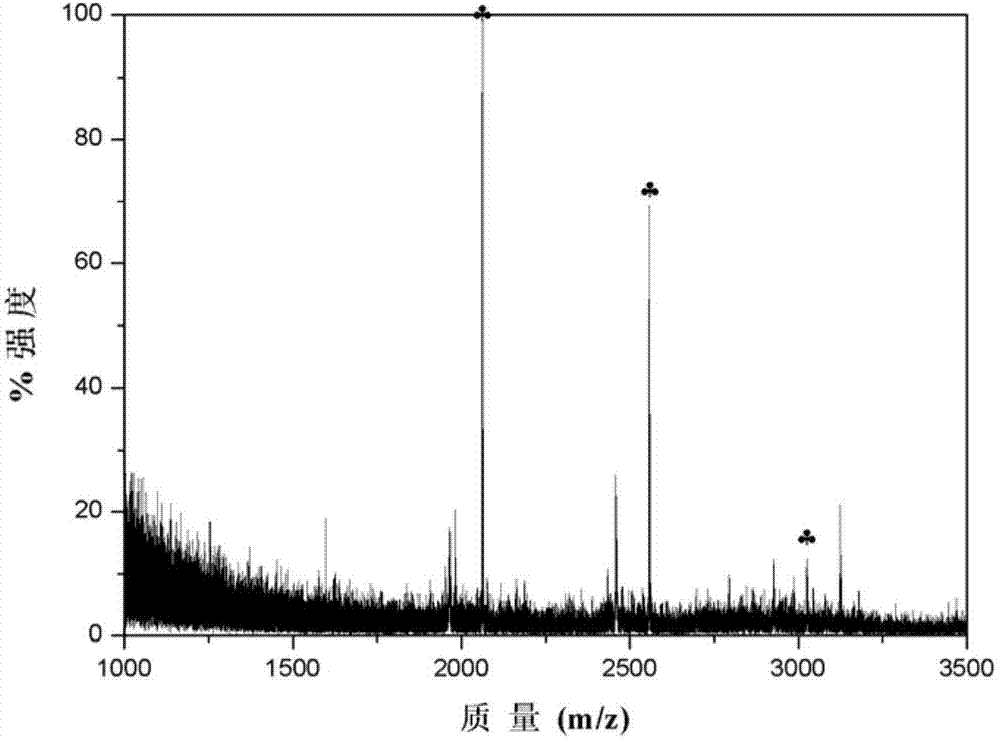

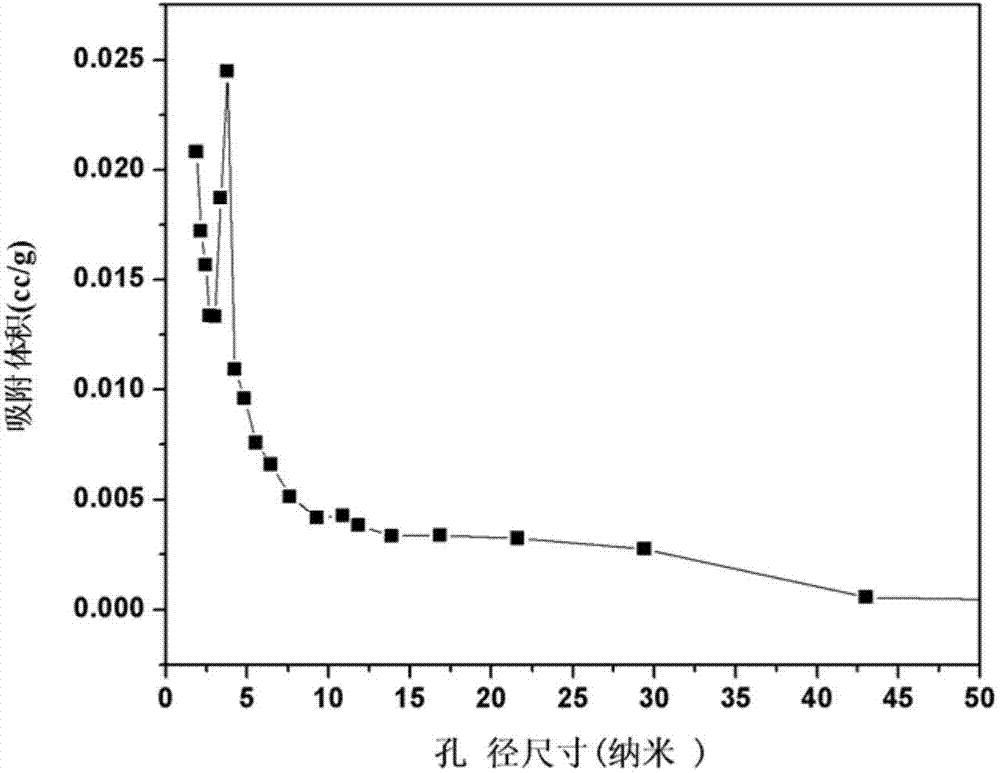

[0029] (2) The polyelectrolyte modified Fe obtained above 3 o 4 and 0.4755g zirconium oxychloride octahydrate were added in 200ml absolute ethanol, and ultrasonic 30min obtained polyelectrolyte modified Fe 3 o 4 suspension. Measure 133ml of absolute ethanol, 27ml of deionized water, and 0.5625ml of ammonia water into a beaker, and stir to form an ethanol solution. Under the conditions of ultrasonic power of 200W and mechanical stirring rate of 150r / h, the above-mentioned ethanol solution was added to the polyelectrolyte modified Fe at a rate of 50ml / h using a syringe pump 3 o 4 in suspension. After reacting for 8 hours, Fe with core-shell structure can be obtain...

Embodiment 2

[0034] (1) At room temperature, weigh 0.415g ZnFe 2 o 4 and 0.600g polyacrylic acid, and ultrasonically disperse the two in 100ml deionized water, and ultrasonically disperse for 30min to obtain ZnFe 2 o 4 Suspension, separated by magnet and washed to obtain polyelectrolyte modified ZnFe 2 o 4 .

[0035] (2) The polyelectrolyte modified ZnFe obtained above 2 o 4and 0.915g zirconium isopropoxide were added in 200ml absolute ethanol, and ultrasonic 30min obtained polyelectrolyte modified ZnFe 2 o 4 suspension. Measure 110ml of absolute ethanol, 60ml of deionized water, and 0.600ml of ammonia water into a beaker, and stir to form an ethanol solution. Under the condition that the ultrasonic power is 150W and the mechanical stirring rate is 100r / h, use a syringe pump to add the above mixed solution to the polyelectrolyte modified ZnFe at a rate of 10ml / h 2 o 4 in suspension. After 10 hours of reaction, ZnFe with core-shell structure can be obtained 2 o 4 ZrO 2 Compos...

Embodiment 3

[0039] (1) At room temperature, weigh 0.220g CoFe 2 o 4 and 0.900g polyethylene sulfonic acid, and ultrasonically disperse the two in 100ml deionized water, and ultrasonically disperse for 30min to obtain CoFe 2 o 4 Suspension, separated by magnet and washed to obtain polyelectrolyte modified CoFe 2 o 4 .

[0040] (2) The polyelectrolyte modified CoFe obtained above 2 o 4 and 0.5250g zirconium n-butoxide were added to 200ml absolute ethanol and ultrasonicated for 30min to obtain polyelectrolyte modified CoFe 2 o 4 suspension. Measure 150ml of absolute ethanol, 10ml of deionized water, and 0.7125ml of ammonia water into a beaker, and stir to form an ethanol solution. Under the conditions of ultrasonic power of 100W and mechanical stirring rate of 75r / h, the above mixed solution was added to the polyelectrolyte modified CoFe at a rate of 10ml / h using a syringe pump. 2 o 4 in suspension. After 12 hours of reaction, the core-shell structure of CoFe 2 o 4 ZrO 2 Compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com