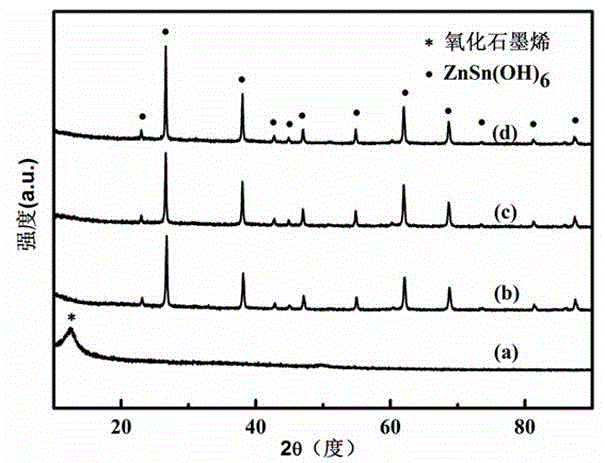

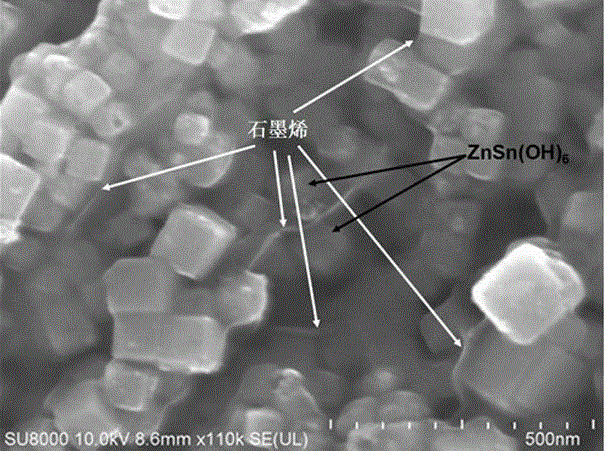

ZnSn (OH)6 nanometer cubic particle/graphene sandwich structure compound light catalyst

A nano-cubic and ene sandwich technology, applied in the field of photocatalysis, can solve the problems of difficult to control product morphology, troublesome post-processing, low product purity, etc., and achieve excellent photocatalytic effect, low production cost, and easy separation and recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

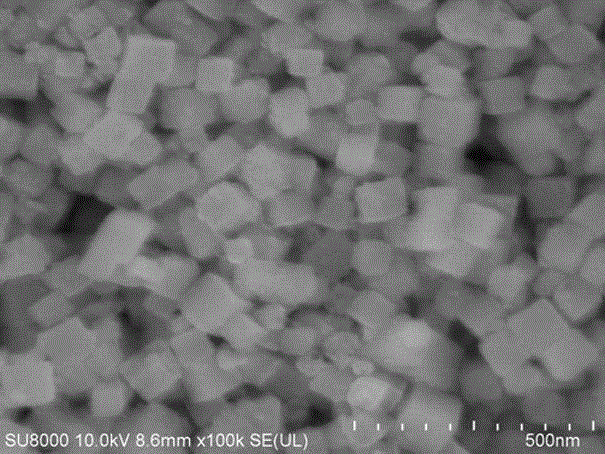

Embodiment 1

[0039] preparation:

[0040] Step 1: Preparation of ZnSn(OH) 6 Nano Cubic Particles:

[0041] (1) Preparation of reaction precursor solution: Dissolve 2 mmol of zinc acetate dihydrate in 80 mL of deionized water at room temperature, then add an equimolar amount of potassium stannate to the above-mentioned zinc acetate solution, and stir evenly to form a reaction precursor solution;

[0042] (2) Hydrothermal reaction: Transfer the obtained precursor solution to a 100mL polytetrafluoroethylene reactor, raise the temperature to 180°C, and keep it warm for 18h;

[0043] (3) Washing and collection of precipitates: the obtained product is naturally cooled to room temperature, washed three times with hydrochloric acid with pH = 2.5, deionized water, and absolute ethanol, centrifuged to collect the precipitate, and vacuum-dried at 60°C to obtain ZnSn(OH) 6 Nanocubic particles.

[0044] The second step: prepare graphene oxide colloidal solution:

[0045] Using natural graphite powd...

Embodiment 2

[0053] Step 1: Preparation of ZnSn(OH) 6 Nano Cubic Particles:

[0054] (1) Preparation of reaction precursor solution: Dissolve 2 mmol of zinc acetate dihydrate in 80 mL of deionized water at room temperature, then add an equimolar amount of potassium stannate to the above-mentioned zinc acetate solution, and stir evenly to form a reaction precursor solution;

[0055] (2) Hydrothermal reaction: Transfer the obtained precursor solution to a 100mL polytetrafluoroethylene reactor, raise the temperature to 180°C, and keep it warm for 18h;

[0056] (3) Washing and collection of precipitates: the obtained product is naturally cooled to room temperature, washed three times with hydrochloric acid with pH = 2.5, deionized water, and absolute ethanol, centrifuged to collect the precipitate, and vacuum-dried at 60°C to obtain ZnSn(OH) 6 Nanocubic particles.

[0057] The second step: prepare graphene oxide colloidal solution:

[0058] Using natural graphite powder as raw material, gra...

Embodiment 3

[0064] Step 1: Preparation of ZnSn(OH)6 nano-cubic particles:

[0065] (1) Preparation of reaction precursor solution: Dissolve 2 mmol of zinc acetate dihydrate in 80 mL of deionized water at room temperature, then add an equimolar amount of potassium stannate to the above-mentioned zinc acetate solution, and stir evenly to form a reaction precursor solution;

[0066] (2) Hydrothermal reaction: transfer the obtained precursor solution into a polytetrafluoroethylene reactor with a capacity of 100 mL, raise the temperature to 180° C., and keep the temperature for 18 hours.

[0067] (3) Washing and collection of precipitates: the obtained product is naturally cooled to room temperature, washed three times with hydrochloric acid with pH = 2.5, deionized water, and absolute ethanol, centrifuged to collect the precipitate, and vacuum-dried at 60°C to obtain ZnSn(OH) 6 Nanocubic particles.

[0068] The second step: prepare graphene oxide colloidal solution:

[0069] Using natural g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com