Niobium-rich lithium-doped potassium tantalate niobate single crystal and preparation method thereof

A technology of potassium tantalum niobate and single crystal, which is applied in the field of potassium tantalum niobate (KTN) crystal and its preparation, can solve the problem that the single crystal of potassium tantalum niobate with rich niobium and the crystal with low curie temperature of potassium tantalum niobate cannot be obtained. Low problems, to achieve the effect of no environmental pollution, controllable growth, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

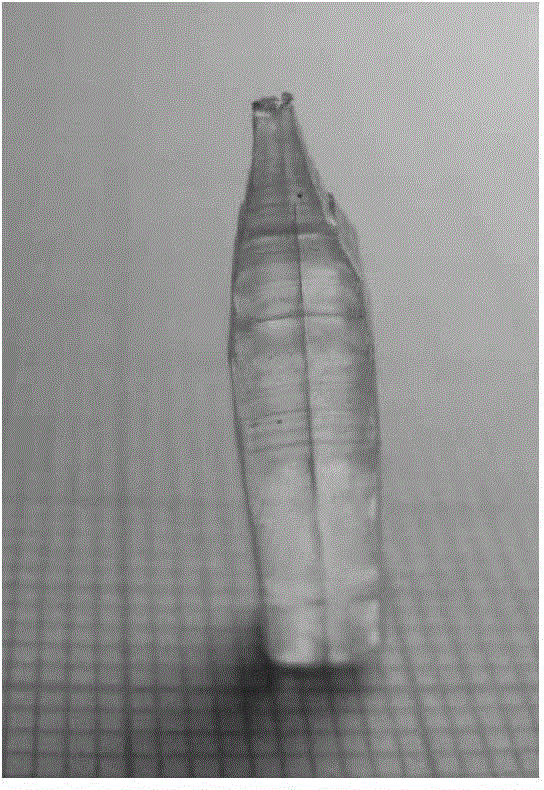

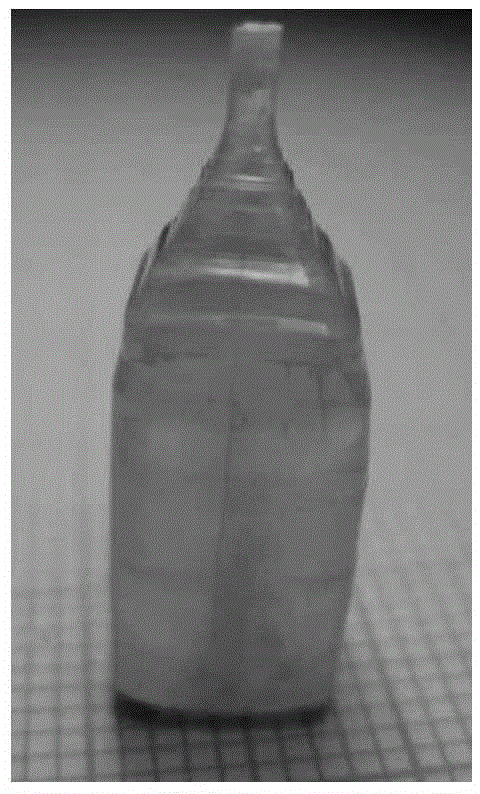

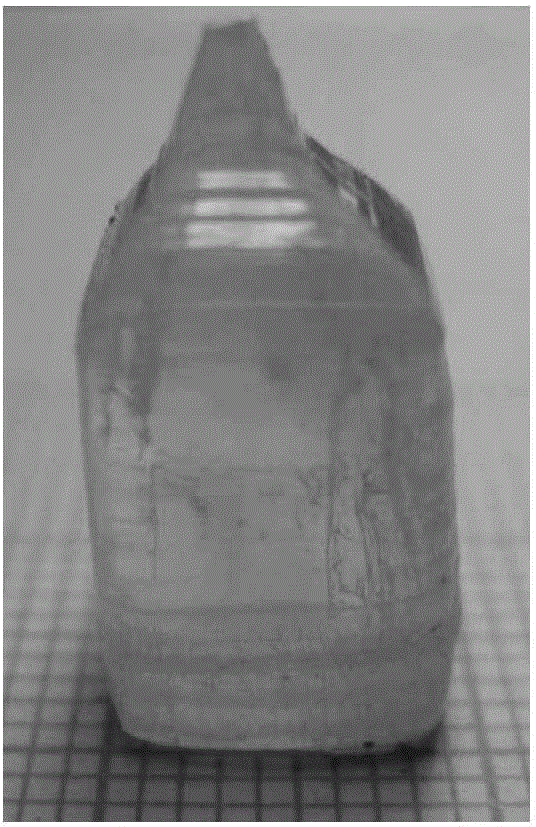

Image

Examples

specific Embodiment approach 1

[0031] Specific implementation mode one: the rich niobium doped lithium tantalum potassium niobate single crystal of the present embodiment, its expression is K 0.95 Li 0.05 Ta 1-x Nb x o 3 , where x=0.50-0.90, the niobium-rich lithium-doped lithium tantalum potassium niobate single crystal has a tetragonal perovskite crystal structure at room temperature.

specific Embodiment approach 2

[0032] Specific embodiment two: the preparation method of the niobium-rich lithium-doped lithium tantalum potassium niobate single crystal described in specific embodiment one is carried out according to the following steps:

[0033] 1. According to potassium carbonate (K 2 CO 3 ), lithium carbonate (Li 2 CO 3 ), tantalum oxide (Ta 2 o 5 ) and niobium oxide (Nb 2 o 5 ) molar ratio is (1~1.25):0.05:(1-x):x, where x=0.50~0.90, and potassium carbonate (K 2 CO 3 ), lithium carbonate (Li 2 CO 3 ), tantalum oxide (Ta 2 o 5 ) and niobium oxide (Nb 2 o 5 ) powder and mix uniformly to obtain mixed powder;

[0034] 2. The mixed powder obtained in step 1 is ball milled;

[0035] 3. Put the mixed powder processed in step 2 into a mold, press it into a tablet, and then put the tablet in a muffle furnace to raise the temperature to 880~920℃ at a heating rate of 140~150℃ / h and keep it for 4~5h. Obtain niobium-rich lithium tantalum potassium niobate multichip;

[0036] 4. Pou...

specific Embodiment approach 3

[0040] Specific embodiment three: what this embodiment is different from specific embodiment two is potassium carbonate (K 2 CO 3 ), lithium carbonate (Li 2 CO 3 ), tantalum oxide (Ta 2 o 5 ) and niobium oxide (Nb 2 o 5 ) The purity of the powder is ≥99.99%; the others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Piezoelectric coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com