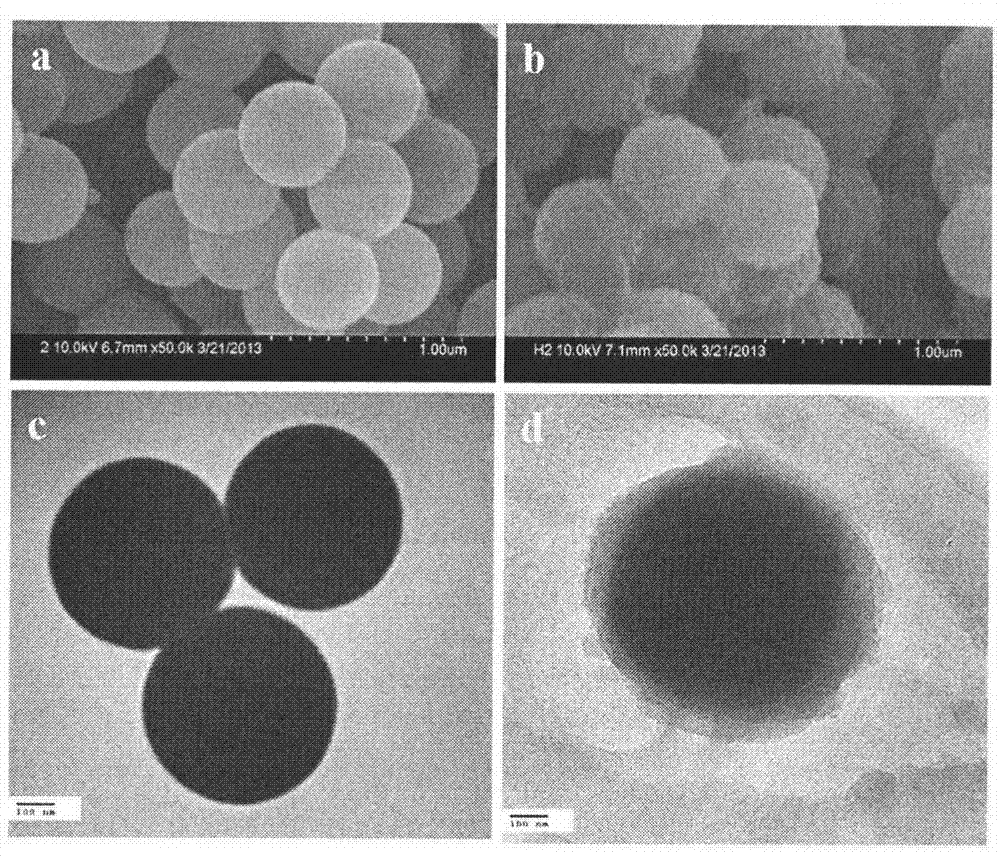

L-carnitine molecularly imprinted microspheres with core-shell structure and preparation method thereof

A technology of molecularly imprinted microspheres and molecularly imprinted membranes, which is applied in the field of core-shell structure molecularly imprinted nano-microspheres and their preparation, can solve problems such as muscle atrophy and muscle soreness, and achieve the effects of low production cost and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1.SiO 2 Preparation of nanospheres: 60ml of absolute ethanol, 9ml of ammonia, 9ml of deionized water were added to a 250ml three-necked flask, and mechanically stirred for 10 minutes to make the solution evenly mixed. Use a syringe to add 4.5ml of ethyl orthosilicate ( TEOS). With the addition of TEOS, the solution gradually turned into a white turbid liquid, and stirring was continued for 3 hours at room temperature. Use a centrifuge to separate the precipitate, wash the precipitate 3 times with deionized water and absolute ethanol, place it on a watch glass, and dry it in an oven at 50°C for 24 hours to obtain SiO 2 White powder.

[0026] 2.SiO 2 Surface activation of microspheres: the dried SiO 2 Place the microspheres in a 100ml beaker, add 25ml of nitric acid and 25ml of deionized mixed solution, ultrasonically disperse, cover with plastic wrap and soak for 24h. SiO after soaking 2 Wash with deionized water to neutral to obtain surface activated SiO 2 The microspheres...

Embodiment 2

[0032] 1. Same as Example 1.

[0033] 2. Same as Example 1.

[0034] 3. Same as Example 1.

[0035] 4. Same as Example 1.

[0036] 5. Same as Example 1.

[0037] 6. The elution of imprinted template molecules: using the method of ultrasonic extraction, the extraction solution is methanol solution, the methanol solution is changed every 30 minutes, the amount of methanol used each time is 100ml, and the total elution time is 300 minutes. After the extraction is completed, rinse with acetone for 1 Second, remove a small amount of fine polymer fragments. Dry under vacuum at 40°C for 24h.

Embodiment 3

[0039] 1. Same as Example 1.

[0040] 2. Same as Example 1.

[0041] 3. Same as Example 1.

[0042] 4. Same as Example 1.

[0043] 5. Preparation of L-carnitine molecularly imprinted microspheres with core-shell structure: Dissolve 1mmol (0.1612g) of template molecule L-carnitine in 20ml methanol, add 4mmol (0.314ml) methacrylic acid (MAA), at room temperature Oscillate at a constant temperature in the gas bath for 2 hours to make the template molecule and the functional monomer fully interact. Take 200mg SiO 2 -RAFT microspheres are dispersed in 50ml methanol solution, and then the methanol mixed solution of L-carnitine and MAA prepared before and 10mmol (1.93ml) crosslinker ethylene glycol dimethacrylate (EGDMA) are added to react The vessel was sealed, nitrogen was passed through to remove oxygen, 10ml of methanol solution containing 40mg of initiator azobisisobutyronitrile (AIBN) was added dropwise with a syringe, and the reaction was carried out at 50°C for 6 hours, then the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com