Preparation process for copper-plate electroplated nickel tungsten electroplated layer of continuous-casting crystallizer

A technology for continuous casting crystallizer and preparation process, which is applied in the field of preparation process for electroplating nickel-tungsten coating on copper plate of continuous casting crystallizer, which can solve the problems of pitting, rough coating, unevenness, etc., and achieve improved wear resistance and stable performance , good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The present invention will be further described from five groups of tests below.

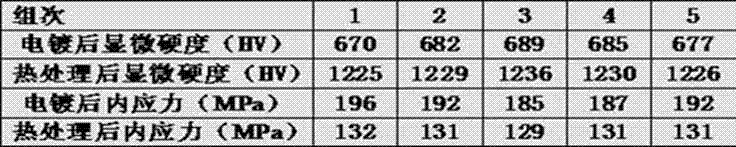

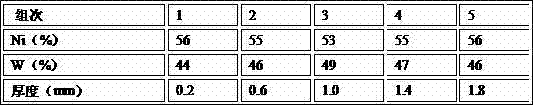

[0032] In the five groups of tests, the composition and thickness of the electroplated nickel-tungsten coating on the copper plates of each continuous casting mold are shown in the table below

[0033]

[0034] The preparation process of the nickel-tungsten alloy electroplating layer on the copper plate of the continuous casting crystallizer includes the following steps: chemical degreasing, sand blasting, electrolytic degreasing, water cleaning, fixing auxiliary tooling, acid activation treatment, electroplating, and then vacuum heat treatment to eliminate the electroplating layer Internal stress, the vacuum heat treatment is at a vacuum degree ≤ 10 -2 Carry out in a Pa vacuum heat treatment furnace, keep the coating at 350-370°C for 2.5-3 hours, and then cool it with argon or nitrogen;

[0035] Component (g / L) 1 2 3 4 5 Nickel sulfamate 50 56 62 69 75 Sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Internal stress | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com