Aerobic granular sludge with pyridine degradation function as well as cultivation and application thereof

An aerobic granular sludge and granular sludge technology, applied in water/sludge/sewage treatment, water pollutants, biological water/sewage treatment, etc. problem, to achieve the effect of high sludge concentration, high degradation efficiency and good settling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

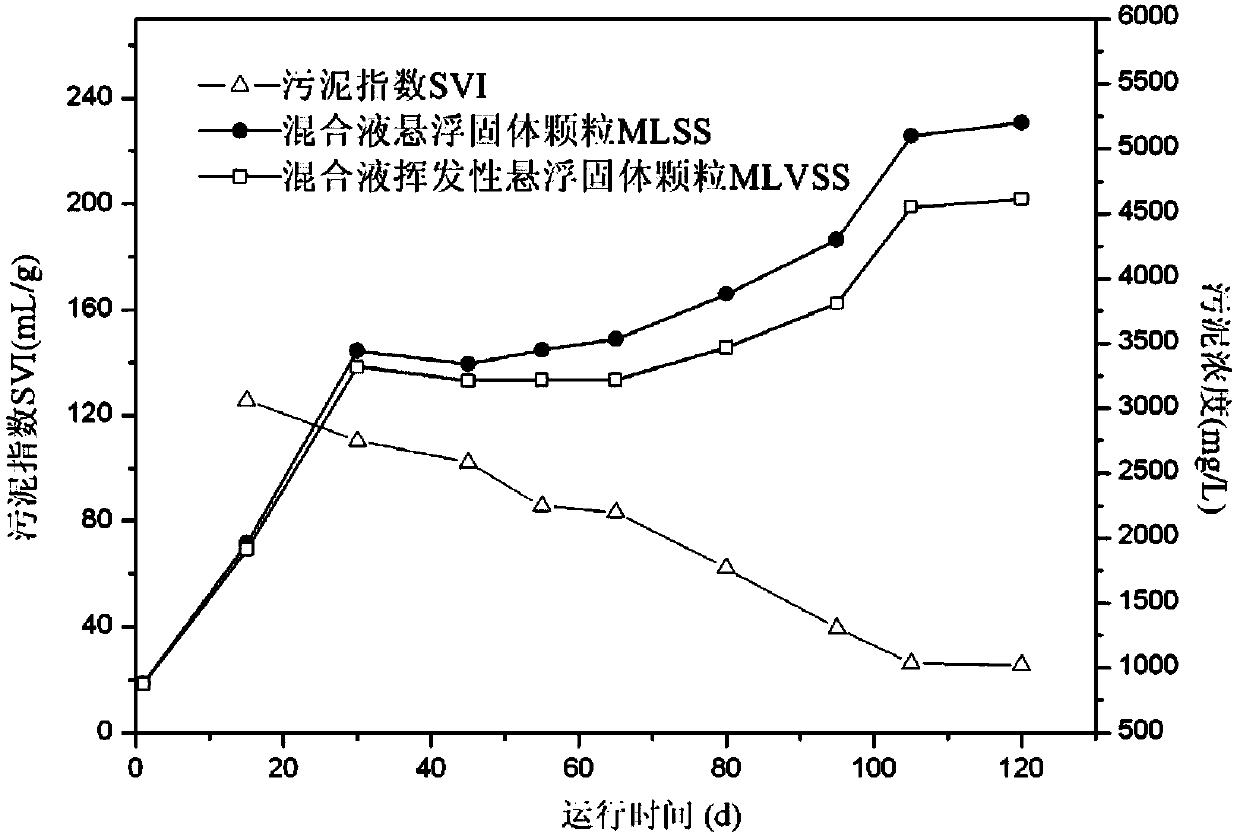

[0028] Embodiment 1: the cultivation of aerobic granular sludge in SBR reactor

[0029] ⑴ SBR reactor operating parameter conditions

[0030] The present invention adopts a sequencing batch reactor (SBR), with a height of 100 cm, an inner diameter of 6 cm, and an effective volume of 2.2 L. The temperature of the reactor is controlled at 30° C. through a water bath. The simulated wastewater containing pyridine was pumped from the bottom of the reactor through a peristaltic pump. There is a drain in the middle of the reactor, and the drain is controlled by a solenoid valve, and the volume exchange rate of the reactor is 50%. The reactor is aerated with an aeration rate of 200L / h through the aeration head to provide sufficient oxygen in the reactor, and at the same time provide high hydraulic shear force for microorganisms to facilitate the formation of aerobic granular sludge. The operation change of water inlet / aeration / sedimentation / drainage in each cycle of the reactor is c...

Embodiment 2

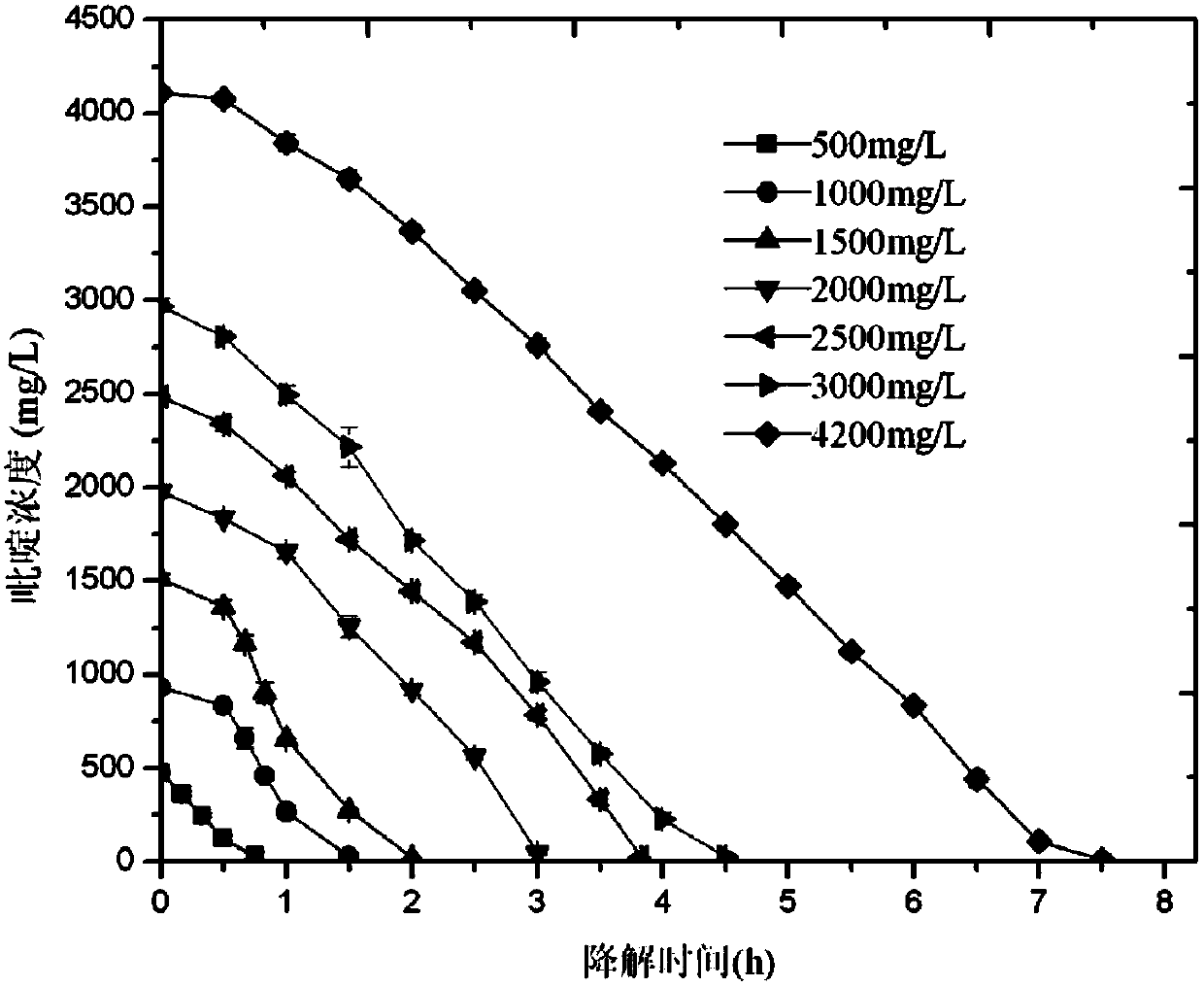

[0043] Example 2: Degradation of pyridine by mature aerobic granular sludge

[0044] Wastewater was prepared according to the composition of pyridine-containing simulated wastewater in Example 1. The initial concentration of pyridine in the reactor after the SBR was fed into the water was about 500mg / L, 1000mg / L, 1500mg / L, 2000mg / L, 2500mg / L, and 3000mg / L. and 4200mg / L. During the operation, the operation cycle was set to 8 hours, the water intake time was set to 5 minutes, the reaction time was set to 7 hours and 40 minutes, the settling time was set to 2 minutes, the drainage time was set to 3 minutes, and the idle time was set to 10 minutes, The aeration rate is 200L / h.

[0045] The results show that (as image 3 ), the mature aerobic granular sludge can completely degrade pyridine in simulated wastewater with an initial pyridine concentration as high as 4200 mg / L in about 7.5 hours. Under the conditions of initial pyridine concentration of 500mg / L, 1000mg / L, 1500mg / L, 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com