Preparation method for synthesizing cordierite material by use of waste ceramic rollers

A technology of cordierite and waste ceramics, which is applied in the field of preparation of cordierite materials using waste ceramic rollers, can solve the problems of low cordierite content and high raw material costs, reduce sintering temperature, improve purity, and realize high value-added circulation The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

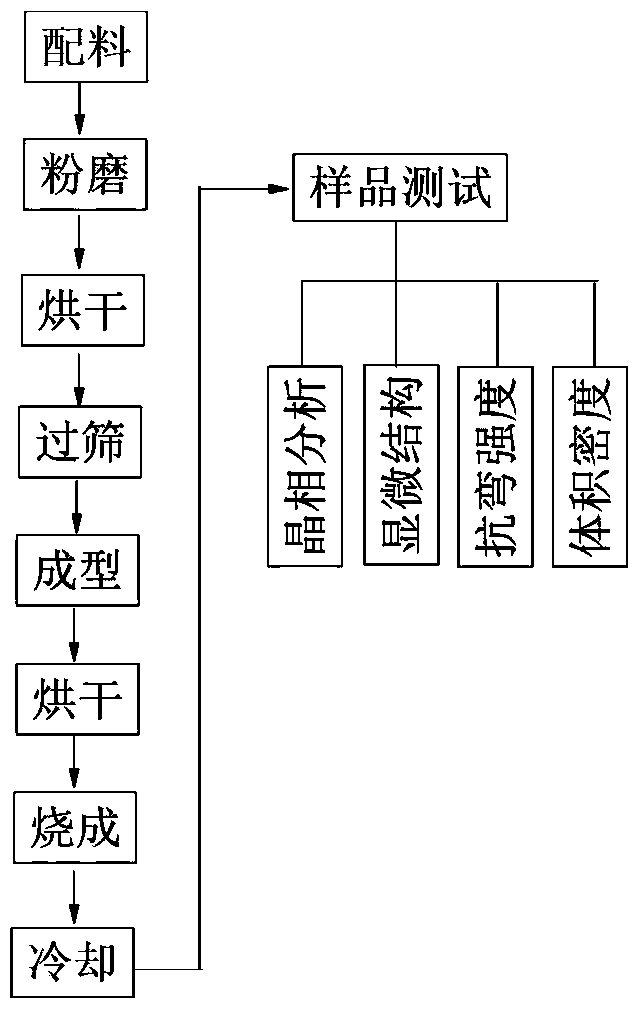

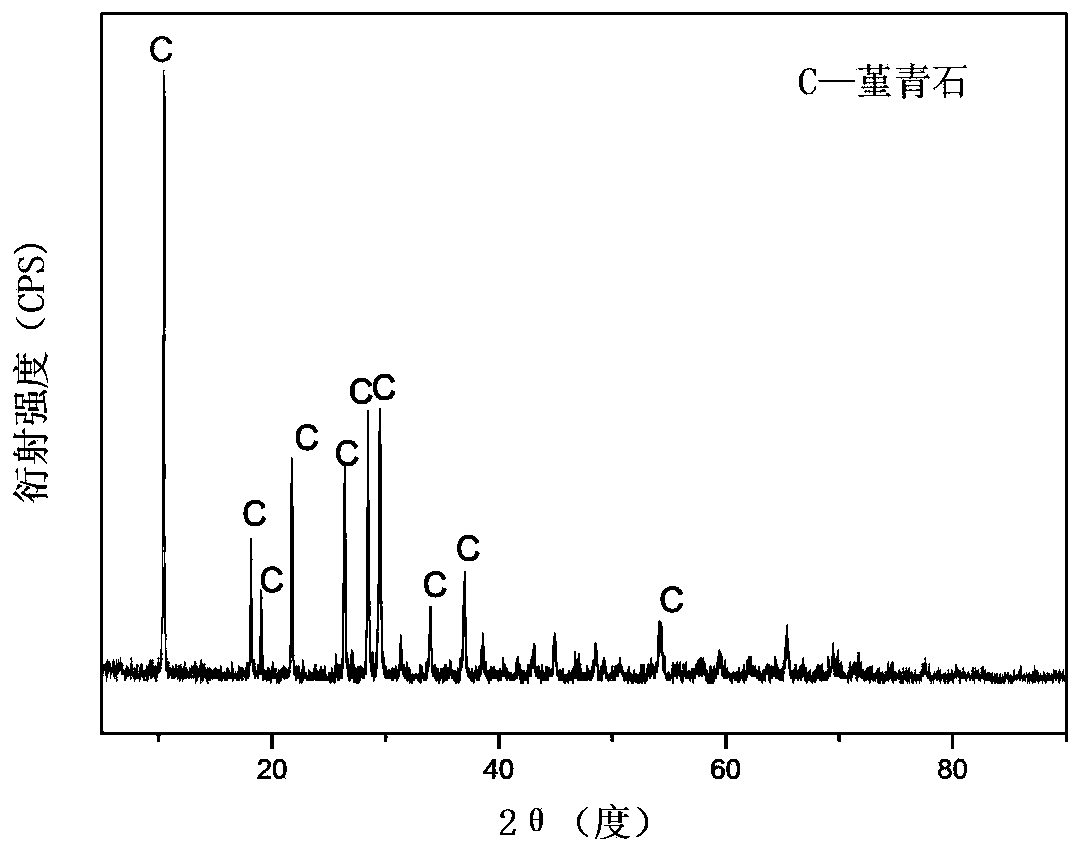

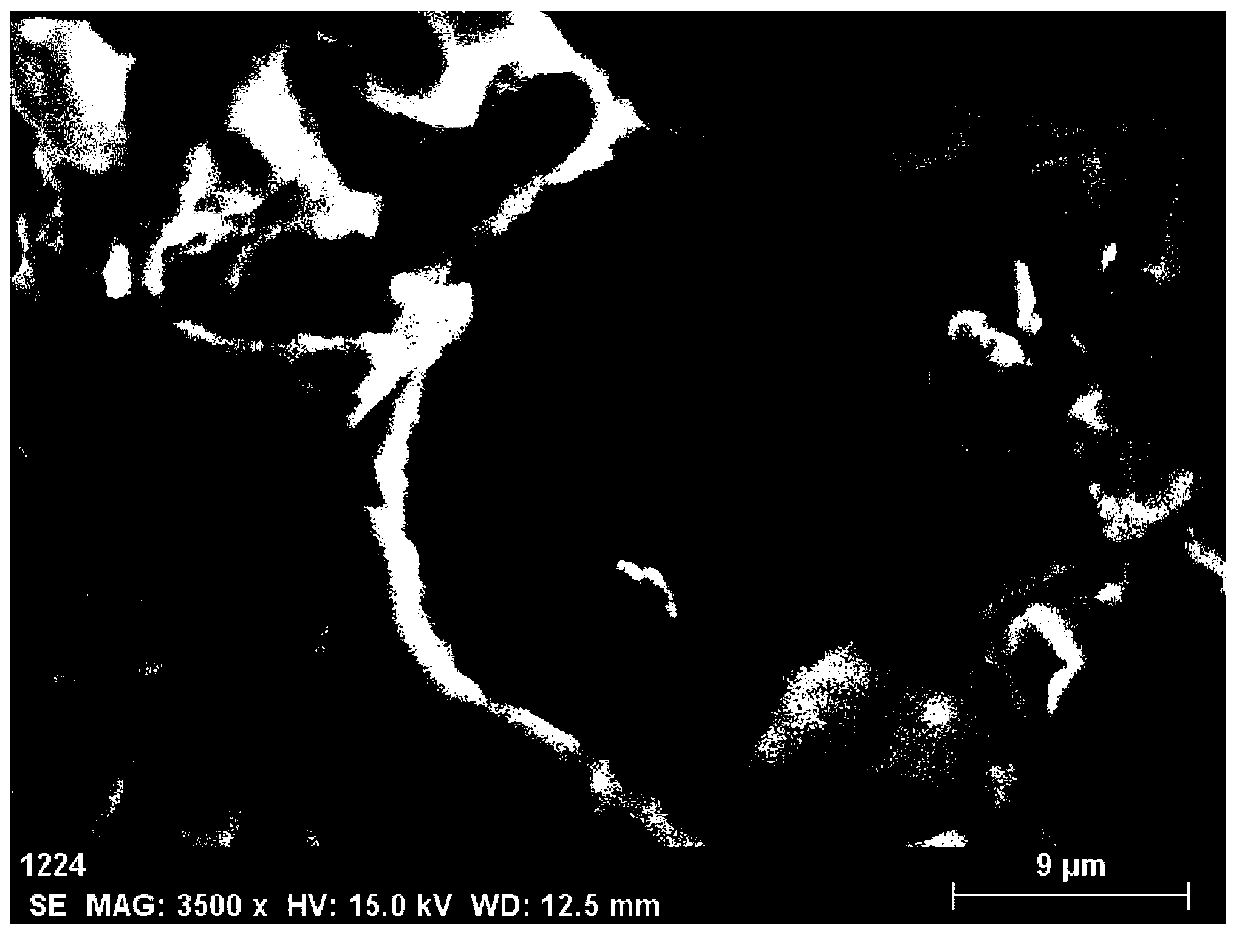

[0019] figure 1 For the process step roadmap of the present invention, refer to the appended figure 1 , The weight ratio of the raw material formula of this example is: waste ceramic roller 40, kaolin 30, talc 24, quartz 6. After the raw materials are mixed according to the ratio, they are ground in a planetary ball mill for 4 hours, material: ball: water = 1:1.5:0.8. The ground slurry is filtered and dehydrated, put into a drying oven at 100°C for 12 hours, crushed and passed through a 100-mesh sieve. The powder is mixed with a binder of 5% polyvinyl alcohol aqueous solution, molded under a pressure of 20MPa, and the molded blank is placed in a drying oven at 100°C for 12 hours. The dry billet is placed in a kiln and fired at high temperature in an air atmosphere. The calcination temperature is 1320°C, the holding time is 4 hours, and it is naturally cooled to room temperature. It is made of cordierite. The crystal phase structure of the sample was analyzed by X-ray diffra...

Embodiment 2

[0021] The weight ratio of the raw material formula of this example is: waste ceramic roller 46, kaolin 24, talc 24, quartz 6. After the raw materials are mixed according to the ratio, they are ground in a planetary ball mill for 4 hours, material: ball: water = 1:1.5:0.8. The ground slurry is filtered and dehydrated, put into a drying oven at 100°C for 12 hours, crushed and passed through a 100-mesh sieve. The powder is mixed with a binder of 5% dextrin powder aqueous solution, and molded under a pressure of 20MPa, and the molded blank is placed in a drying oven at 100°C for 12 hours. The dry billet is placed in a kiln and fired at high temperature in an air atmosphere. The calcination temperature is 1380°C, the holding time is 2 hours, and it is naturally cooled to room temperature. It is made of cordierite. After testing, the content of cordierite in this material is 92%, the bending strength is 78MPa, and the bulk density is 2.04g / cm 3 .

Embodiment 3

[0023] The weight ratio of the raw material formula of this example is: waste ceramic roller 50, kaolin 20, talc 24, quartz 6. After the raw materials are mixed according to the ratio, they are ground in a planetary ball mill for 4 hours, material: ball: water = 1:1.5:0.8. The ground slurry is filtered and dehydrated, put into a drying oven at 100°C for 12 hours, crushed and passed through a 100-mesh sieve. The powder is mixed with a binder of carboxymethyl cellulose with a concentration of 5%, and molded under a pressure of 20MPa, and the molded blank is placed in a drying oven at 100°C for 12 hours. The dry billet is placed in a kiln and fired at high temperature in an air atmosphere. The calcination temperature is 1350°C, the holding time is 2 hours, and it is naturally cooled to room temperature. It is made of cordierite. After testing, the content of cordierite in this material is 92%, the bending strength is 58MPa, and the bulk density is 1.98g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com