Solid state fermentation method of mixed bacteria of clostridium butyricum and bacillus coagulans

A technology of Bacillus coagulans and solid-state fermentation, applied in the field of microbial fermentation, to achieve the effects of simple fermentation management, low energy consumption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Clostridium butyricum activation and configuration of seed liquid medium (g / L): glucose 8, tryptone 10, yeast extract 4, K 2 HPO 4 5. MgSO 4 ·7H 2 O0.2, MnSO 4 ·H 2 O0.2, solvent is water, pH7.4. The activation medium is divided into test tubes, each with a capacity of 10 mL; the seed medium is divided into 50 mL flat-bottomed flasks, each with a capacity of 40 mL, and sterilized at 121°C for 20 minutes.

[0037] Put the strains frozen in the glycerol tube into the activated medium, and anaerobically culture at 37°C for 18 hours; the activated Clostridium butyricum TK2 was inoculated into the seed medium with an inoculum size of 5%, and cultured anaerobically at 37°C for 24 hours .

Embodiment 2

[0039] The configuration of Bacillus coagulans TQ33 seed medium (g / L): yeast extract 10, glucose 60, peptone 10, MgSO 4 ·7H 2 O0.5, the solvent is water, pH7.2, 50mL of seed culture medium is divided into each 250mL Erlenmeyer flask, and sterilized at 115°C for 20min.

[0040] Inoculate the Bacillus coagulans TQ33 preserved on the slant of the test tube into the seed medium, the inoculum amount is 1-3 rings, and culture at 37°C and 180r / min for 20h with shaking.

[0041] 2. Configuration of solid-state fermentation medium

Embodiment 3

[0043] Preparation of enzymatically hydrolyzed soybean meal: the weight ratio of soybean meal to water is 1:2, the amount of neutral protease is 1000u per gram of soybean meal, and the enzyme is hydrolyzed for 3 hours. The neutral protease ZDB-G-20 used was purchased from Tianjin Nuoao Technology Development Co., Ltd.

[0044] Configuration of solid-state fermentation medium: enzymolysis soybean meal 33.1, rice bran 6.6, MgSO 4 ·7H 2 O0.12, MnSO 4 ·7H 2 O0.12, add water to 100%, the volume of each 100mL triangular bottle is 70g, and the pH is natural. First dissolve the inorganic salt with water, then add enzymatically hydrolyzed soybean meal and rice bran in sequence while stirring, and finally make it evenly mixed, divide and sterilize, and sterilize at 121°C for 20 minutes.

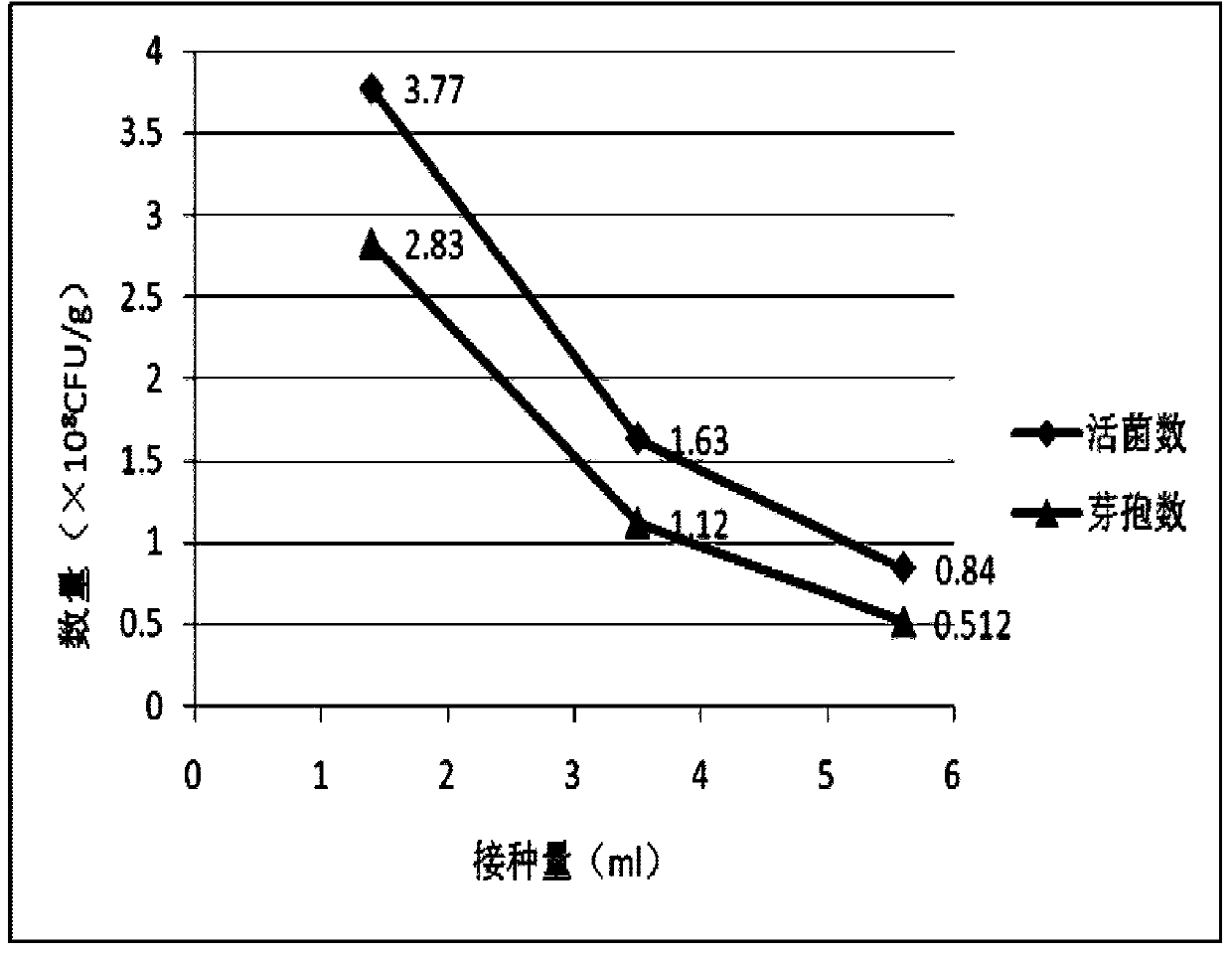

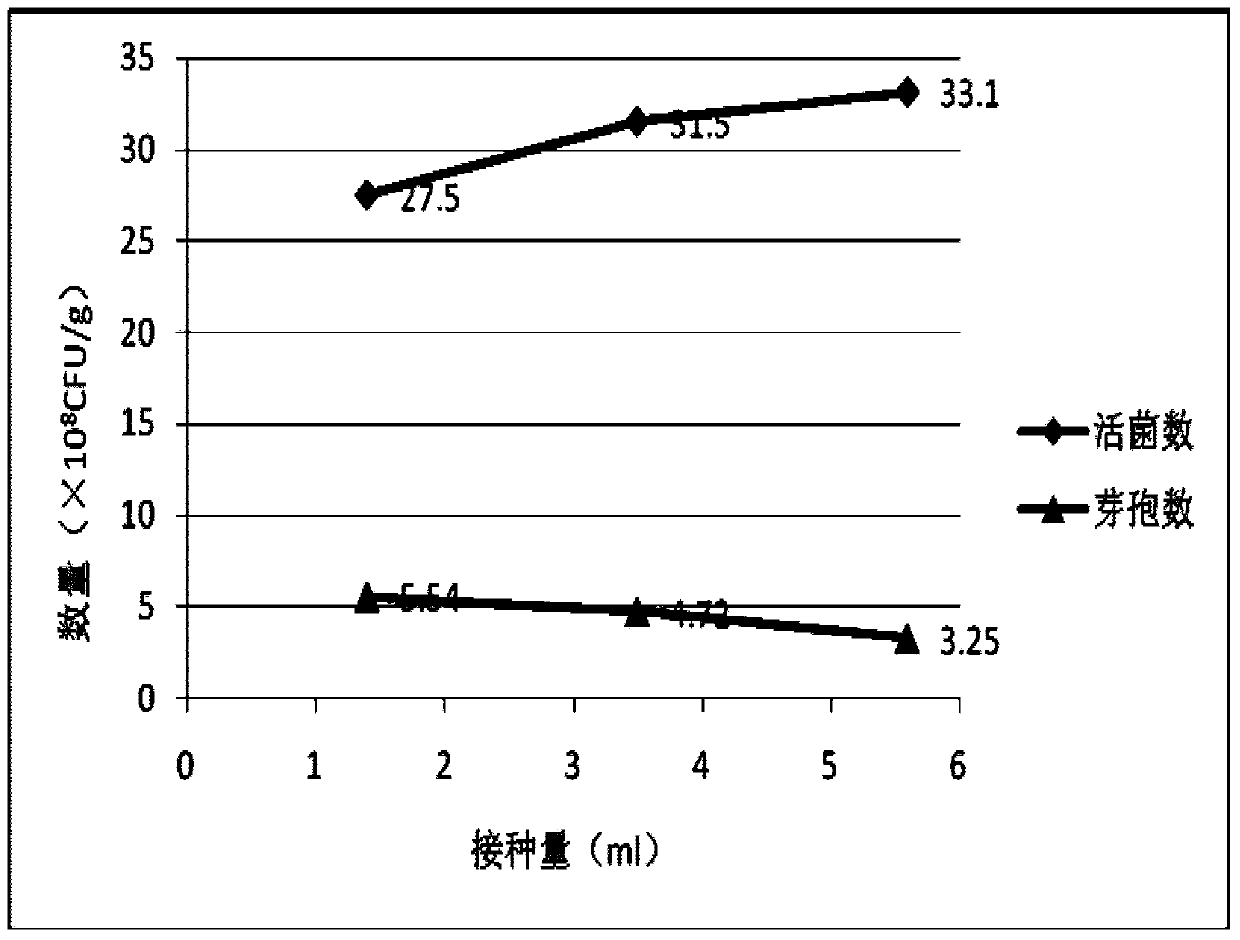

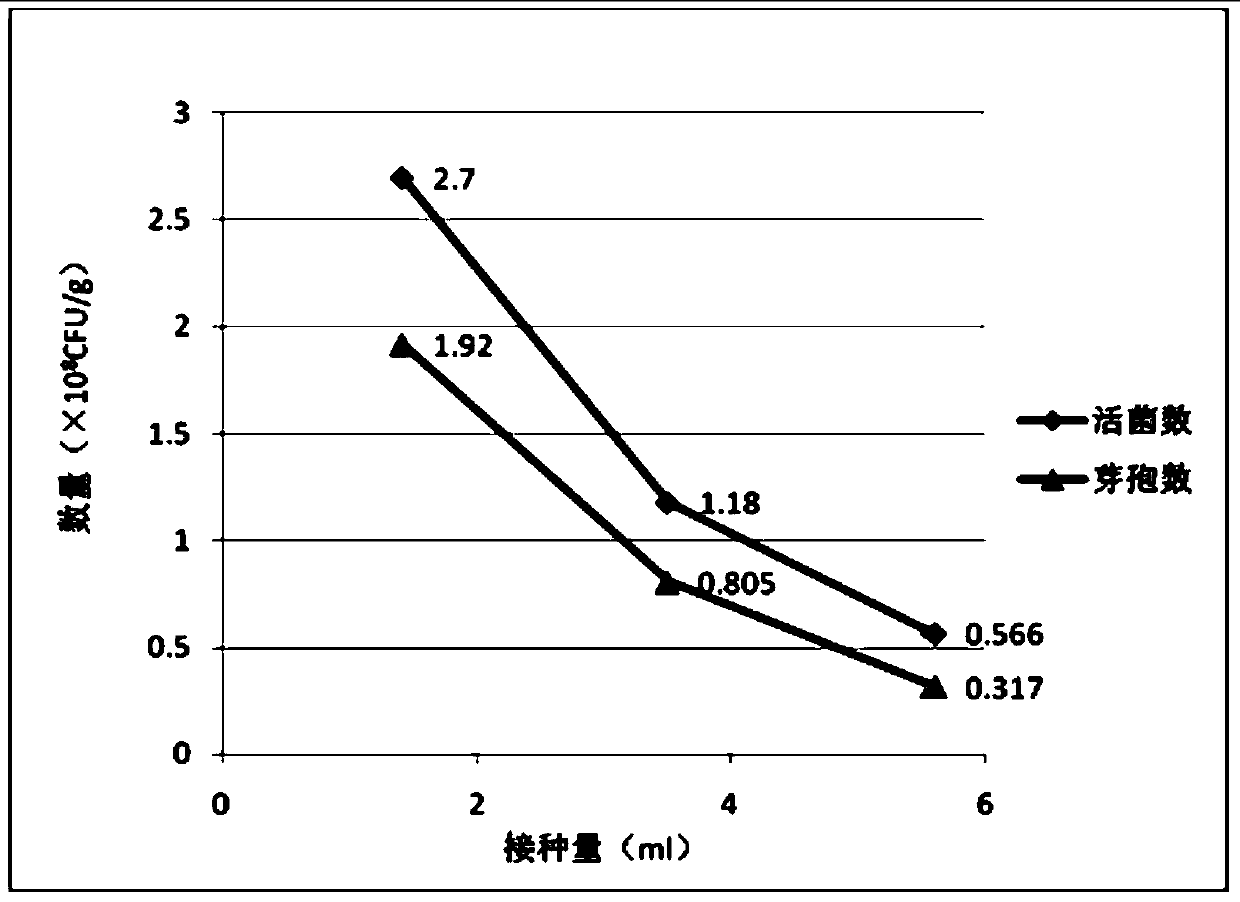

[0045] 3. Effect of different inoculum amounts of Bacillus coagulans TQ33 on solid-state anaerobic fermentation of mixed bacteria

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com