High-density boron carbide composite material and preparation method thereof

A technology of composite materials and boron carbide, which is applied in the field of high-density boron carbide composite materials and its preparation, can solve the problems of boron carbide density reduction, reduced performance, and large resistance to grain boundary movement, so as to save resources and energy , saving production cost, short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

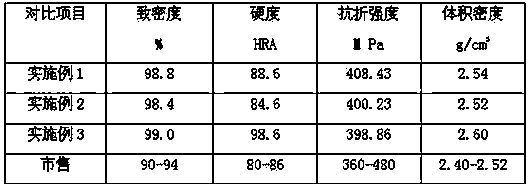

Examples

Embodiment 1

[0019] Embodiment 1: a kind of high-density boron carbide composite material, the weight percentage of each described component is as follows: 75% boron carbide, 10% Al 4 C 3 and Al 2 o 3 A mixture of 3% phenolic resin, 3% graphite, 3% TiO 2 , 6% Fe and Cu. Concrete preparation method is as follows:

[0020] 1) Weigh the boron carbide powder with the corresponding weight ratio, put it into the stirring pulverizer for pulverization and stirring, after stirring for 30 minutes, add 10% Al in turn 4 C 3 and Al 2 o 3 A mixture of powder and 3% TiO 2 Crystal powder, fully stirred and mixed for 5 hours, the solid powder after stirring and mixing was filtered through a sieve with a pore size of 1-3 μm, and weighed for later use;

[0021] 2) Add deionized water to the filtered solid powder, stir, mix and dilute to form a slurry, add the above solid-liquid mixed slurry into a ball mill, and ball mill for 8 hours at room temperature;

Embodiment 2

[0026] Embodiment 2: a kind of high-density boron carbide composite material, the weight percent of each described component is as follows: 88% boron carbide, 6% Al 4 C 3 and Al 2 o 3 A mixture of 1% phenolic resin, 2% graphite, 1% TiO 2 , 2% Si. Concrete preparation method is as follows:

[0027] 1) Weigh the boron carbide powder with the corresponding weight ratio, put it into the stirring pulverizer for crushing and stirring, after stirring for 30 minutes, add 6% Al in turn 4 C 3 and Al 2 o 3 A mixture of powder and 1% TiO 2 Crystal powder, fully stirred and mixed for 5 hours, the solid powder after stirring and mixing was filtered through a sieve with a pore size of 1-3 μm, and weighed for later use;

[0028] 2) Add deionized water to the filtered solid powder, stir, mix and dilute to form a slurry, add the above solid-liquid mixed slurry into a ball mill, and ball mill for 10 hours at room temperature;

[0029] 3) The solid slurry after ball milling is added to ...

Embodiment 3

[0033] Embodiment 3: a kind of high-density boron carbide composite material, the weight percentage of each described component is as follows: 82% boron carbide, 8% Al 4 C 3 and Al 2 o 3 A mixture of 2% phenolic resin, 2% graphite, 1% TiO 2 , 5% Mg and Fe. Concrete preparation method is as follows:

[0034] 1) Weigh the boron carbide powder with the corresponding weight ratio, put it into the stirring pulverizer for pulverization and stirring, after stirring for 30 minutes, add 8% Al in turn 4 C 3 and Al 2 o 3 A mixture of powder and 1% TiO 2 Crystal powder, fully stirred and mixed for 5 hours, the solid powder after stirring and mixing was filtered through a sieve with a pore size of 1-3 μm, and weighed for later use;

[0035] 2) Add deionized water to the filtered solid powder, stir, mix and dilute to form a slurry, add the above solid-liquid mixed slurry into a ball mill, and ball mill for 8 hours at room temperature;

[0036] 3) The solid slurry after ball millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com