Carbon nano tube reinforced aluminum alloy core aluminum stranded wire and preparation method thereof

A technology of carbon nanotubes and aluminum cored wire, which is applied in the direction of metal/alloy conductors, cable/conductor manufacturing, power cables, etc., can solve the restrictions on the popularization and application of carbon fiber composite aluminum cored wires, the application constraints of heat-resistant aluminum alloy wires, Transportation, construction and maintenance are inconvenient to achieve the effect of reducing construction and operation and maintenance costs, reducing the amount of steel used, and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

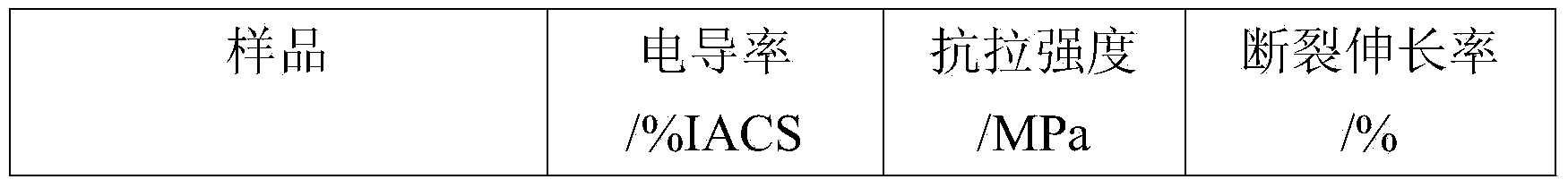

Examples

Embodiment 1

[0023] 1) Weigh the ingredients needed to prepare carbon nanotube reinforced aluminum alloy materials according to the following weight percentages for later use: 4% carbon nanotubes, 0.4% magnesium, 0.7% manganese, 0.1% chromium, 0.01% nickel, 0.1% titanium, copper 0.01%, other unavoidable impurities ≤ 0.01%, the balance is aluminum;

[0024] 2) Put the above ingredients into a ball mill, add paraffin for ball milling, add 0.5ml of paraffin per gram of carbon nanotube reinforced aluminum alloy material ingredients, ball milling time 12h, speed 600r / min, ball to material mass ratio 15:1, The mass ratio of large and small balls is 1:3 to obtain ball milled powder;

[0025] 3) The ball-milled powder obtained in step 2) was vacuum hot-pressed at a temperature of 590°C and a pressure of 10T for 15 hours to prepare a carbon nanotube-strengthened aluminum alloy blank;

[0026] 4) Heating the blank obtained in step 3) at 560°C, and then hot-extruding it at a pressure of 15T to obtai...

Embodiment 2

[0030] 1) The ingredients needed to prepare carbon nanotube reinforced aluminum alloy materials are weighed according to the following weight percentages for later use: carbon nanotubes 5%, magnesium 0.6%, manganese 0.4%, chromium 0.08%, nickel 0.01%, titanium 0.09%, copper 0.01%, other unavoidable impurities ≤ 0.01%, the balance is aluminum.

[0031] 2) Put the above ingredients into a ball mill, add polyethylene glycol for ball milling, add 0.4ml polyethylene glycol per gram of carbon nanotube reinforced aluminum alloy material ingredients, ball milling time 12h, speed 600r / min, ball material quality The ratio is 20:1, the mass ratio of large and small balls is 1:2, and the ball milled powder is obtained;

[0032] 3) The ball-milled powder obtained in step 2) was vacuum hot-pressed at a temperature of 600°C and a pressure of 12T for 10 hours to prepare a carbon nanotube-strengthened aluminum alloy blank;

[0033] 4) Heating the billet obtained in step 3) at 520°C, and then ...

Embodiment 3

[0037] 1) The ingredients needed to prepare carbon nanotube reinforced aluminum alloy materials are weighed according to the following weight percentages for later use: carbon nanotubes 5%, magnesium 0.8%, manganese 0.5%, chromium 0.08%, nickel 0.01%, titanium 0.08%, copper 0.01%, other unavoidable impurities ≤ 0.01%, the balance is aluminum.

[0038]2) Put the above ingredients into a ball mill, add polyvinyl alcohol for ball milling, add 0.6ml of polyvinyl alcohol per gram of carbon nanotube reinforced aluminum alloy material composition, ball milling time 8h, speed 800r / min, ball material mass ratio is 25:1, the mass ratio of large and small balls is 1:3, and the ball mill powder is obtained;

[0039] 3) The ball-milled powder obtained in step 2) was vacuum hot-pressed at a temperature of 610°C and a pressure of 8T for 12 hours to prepare a carbon nanotube-strengthened aluminum alloy blank;

[0040] 4) Heating the blank obtained in step 3) at 550°C, and then hot-extruding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com