Supported gold catalyst, its preparation and its application

A gold catalyst and supported technology, which is applied in the field of chemical catalytic materials and chemical applications, can solve the problems of serious environmental pollution, environmental pollution, loss of metal catalysts, etc., and achieve the effects of less consumption of precious metals, good catalytic activity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

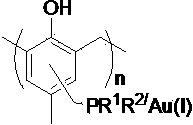

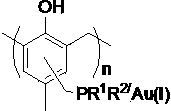

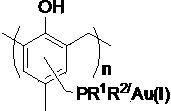

Image

Examples

Embodiment 1

[0033] a. Chloromethylation of ordered mesoporous phenolic resin

[0034] Mix 20 grams of ordered mesoporous phenolic resin with 100 grams of chloromethyl ether and 21 grams of aluminum chloride (added three times with an interval of 1 hour each time) at a temperature of 0°C, and then proceed for 12 hours under argon protection Chloromethylation reaction to prepare a chloromethylated ordered mesoporous phenolic resin, the reaction temperature of which is 25°C.

[0035] b. Phosphine ligand functionalization of ordered mesoporous phenolic resin

[0036] Dissolve 48 grams of diphenylphosphonium chloride in 89 grams of anhydrous tetrahydrofuran, add 2 grams of lithium and stir for 3 hours, add the resulting solution to 32 grams of the chloromethylated ordered mesoporous phenolic resin prepared above, and continue the reaction After 12 hours, an ordered mesoporous phenolic resin functionalized with phosphine ligands was prepared.

[0037] c. Preparation of supported gold catalyst

[0038] ...

Embodiment 2

[0040] a. Chloromethylation of ordered mesoporous phenolic resin

[0041] Mix 20 grams of ordered mesoporous phenolic resin with 100 grams of chloromethyl ether and 21 grams of aluminum chloride (added three times with an interval of 1 hour each time) at a temperature of 0°C, and then proceed for 12 hours under argon protection Chloromethylation reaction to prepare a chloromethylated ordered mesoporous phenolic resin, the reaction temperature of which is 25°C.

[0042] b. Phosphine ligand functionalization of ordered mesoporous phenolic resin

[0043] 78 g of bis(4-trifluoromethyl)phenylphosphonium chloride was dissolved in 89 g of anhydrous tetrahydrofuran, 2 g of lithium was added and the reaction was stirred for 3 hours, and the resulting solution was added to the chloromethylated ordered medium prepared above. 32 grams of porous phenolic resin, continued to react for 12 hours, prepared ordered mesoporous phenolic resin functionalized with phosphine ligands.

[0044] c. Preparatio...

Embodiment 3

[0047] a. Chloromethylation of ordered mesoporous phenolic resin

[0048] Mix 20 grams of ordered mesoporous phenolic resin with 100 grams of chloromethyl ether and 21 grams of aluminum chloride (added three times with an interval of 1 hour each time) at a temperature of 0°C, and then proceed for 12 hours under argon protection Chloromethylation reaction to prepare a chloromethylated ordered mesoporous phenolic resin, the reaction temperature of which is 25°C.

[0049] b. Phosphine ligand functionalization of ordered mesoporous phenolic resin

[0050] Dissolve 62 grams of bis(4-methoxy)phenylphosphine chloride in 89 grams of anhydrous tetrahydrofuran, add 2 grams of lithium and stir for 3 hours, and add the resulting solution to the chloromethylated ordered mesopores prepared above 32 grams of phenolic resin, continued to react for 12 hours to prepare ordered mesoporous phenolic resin functionalized with phosphine ligands.

[0051] c. Preparation of supported gold catalyst

[0052] Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com