Color fluorescent anti-counterfeiting invisible ink powder and preparation method thereof

A fluorescent and toner technology, which is applied in the field of toner manufacturing, can solve the problems of adverse effects on printing performance, single tone of excitation light, and weak anti-counterfeiting reliability, and achieve excellent fluorescent anti-counterfeiting characteristics, wide application prospects, and improved anti-counterfeiting reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

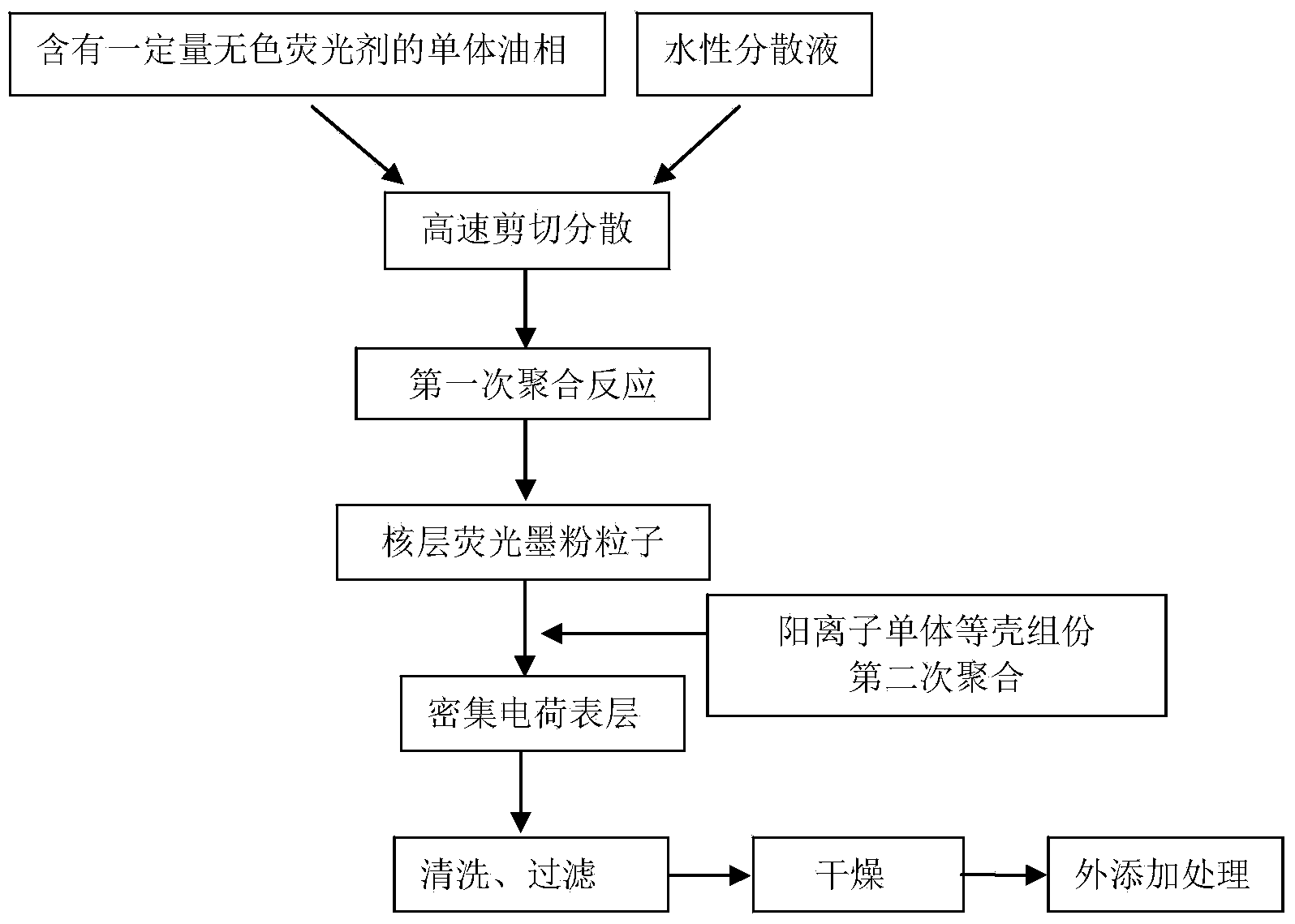

[0033] see figure 1 , the present invention also provides the preparation method of the above-mentioned fluorescent anti-counterfeiting invisible toner, comprising the steps of:

[0034] (1) Dissolve the colorless fluorescent agent, wax, charge control agent and additives according to the ratio, and disperse them in the toner resin monomer to form a monomer oil phase;

[0035] (2) Add the above-mentioned monomer oil phase to the aqueous dispersion liquid, and after high-speed shear suspension granulation, transfer to the reactor, and perform the first temperature-rising polymerization reaction to obtain nuclear layer fluorescent toner particles;

[0036] (3) Using the above-mentioned toner particles as the core layer, adding cationic monomers and water-soluble initiators for the second polymerization reaction, so that the outer surface of the toner particles is evenly distributed with a densely charged surface layer;

[0037] (4) The product after the second polymerization re...

Embodiment 1

[0058] 81 parts of styrene, 19 parts of n-butyl acrylate, 0.6 parts of divinylbenzene, 1.0 parts of n-dodecanethiol, 2 parts of positive charge control agent, 8 parts of ester wax, colorless red fluorescent dye DFSB- 1.2 parts of C7 (manufactured by Risk Reactor), 0.8 parts of colorless blue fluorescent dye DFSB-C0 (manufactured by Risk Reactor), and the above components were dissolved and mixed uniformly at room temperature through a grinding disperser to prepare a monomer oil phase.

[0059] In addition, an aqueous solution of 100 parts of deionized water dissolved in 13 parts of magnesium chloride was slowly added to an aqueous solution of 200 parts of deionized water dissolved in 8.3 parts of sodium hydroxide, dispersed at high speed for 1 hour, and then ultrasonically matured at room temperature for 4 hours to obtain magnesium hydroxide suspension Dispersions.

[0060] Then 2 parts of methyl methacrylate and 0.2 part of dimethyl diallyl ammonium chloride were dispersed in...

Embodiment 2

[0063] Change 1.2 parts of the colorless red fluorescent dye DFSB-C7 (manufactured by Risk Reactor) to 0.8 parts in Example 1, and change 0.8 parts of the colorless blue fluorescent dye DFSB-C0 (manufactured by Risk Reactor) to colorless green Fluorescent dye DFSB-K43 (manufactured by Risk Reactor) 1.2 parts, other operations are consistent with Example 1. The obtained yellow light (Y) invisible anti-counterfeiting toner characteristic evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com