Preparation method of graphene

A technology of graphene and graphite, which is applied in the field of new material synthesis, can solve the problems of low yield and high number of graphene layers, and achieve the effects of high yield, strong conductivity and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of graphene, comprises the following steps:

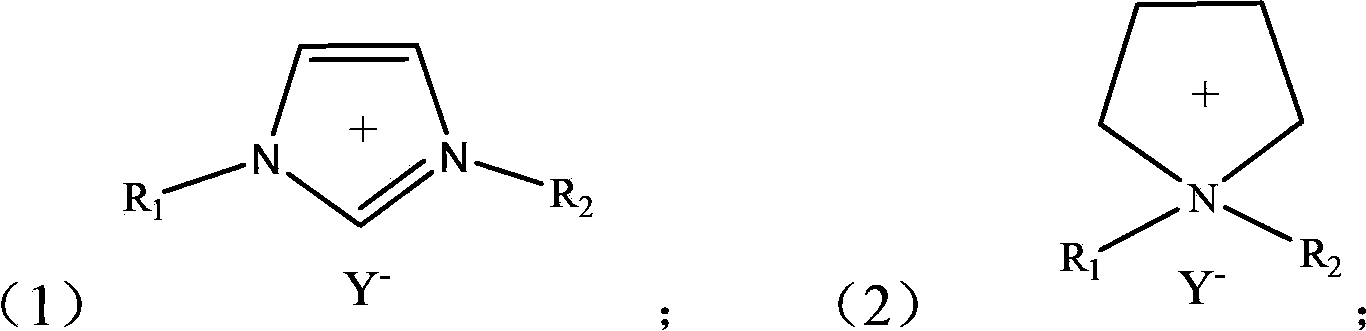

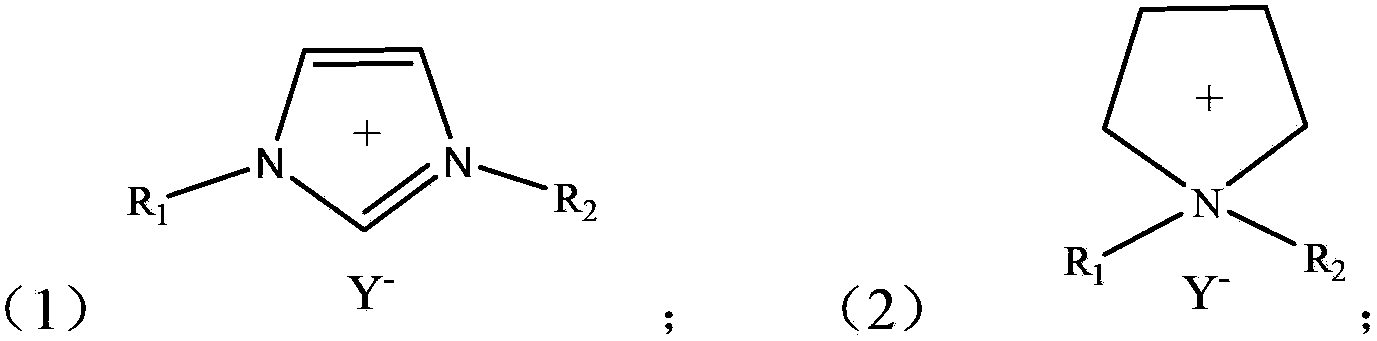

[0025] (1) Mix 5g of graphite with a purity of 99.5% and 5g of 1-butyl-3-methylimidazole bistrifluoromethanesulfonimide salt, and use an ultrasonic machine with a power of 1000W to ultrasonicate the mixture for 24 hours. Hour, obtain intercalated graphite;

[0026] (2) Place the above-mentioned intercalated graphite in a reactor with argon (400mL / min) atmosphere, and raise the ambient temperature of the intercalated graphite to 900°C at a heating rate of 30°C / min, and keep it for 0.5 hours, Then it was lowered to room temperature in an argon (400 mL / min) atmosphere, and the reaction product was collected to obtain graphene.

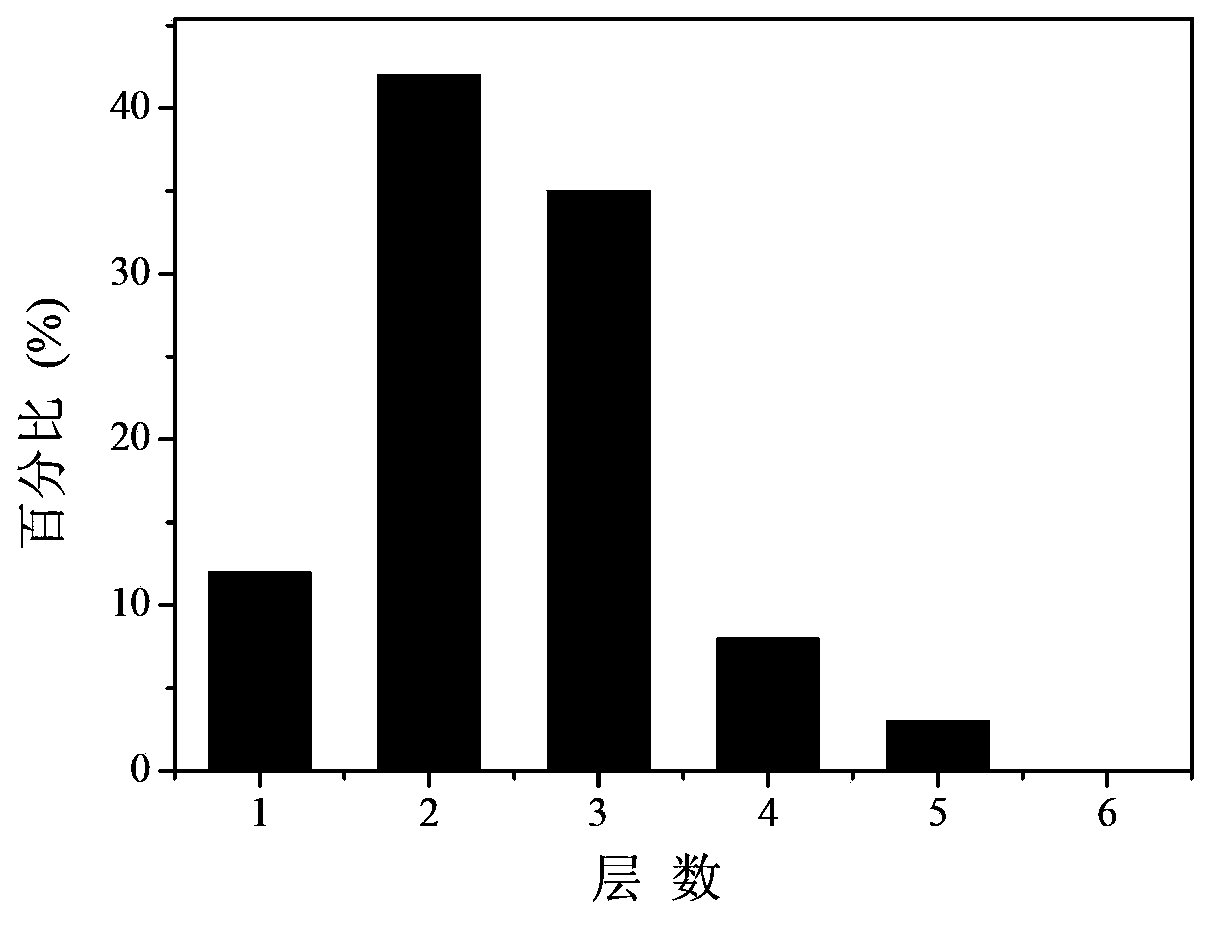

[0027] Adopt atomic force microscope (AFM) to observe 100 parts of graphene prepared in this embodiment, its layer number distribution result is as follows figure 1 shown. figure 1 It is the distribution diagram of the number of layers of graphene prepared in Example 1 of...

Embodiment 2

[0029] A kind of preparation method of graphene, comprises the following steps:

[0030] (1) Mix 10g of graphite with a purity of 99.5% and 15g of 1-butyl-3-methylimidazole bistrifluoromethanesulfonimide salt, and use an ultrasonic machine with a power of 1000W to ultrasonicate the mixture for 36 Hour, obtain intercalated graphite;

[0031] (2) Place the above-mentioned intercalated graphite in a reactor with argon (300mL / min) atmosphere, and raise the ambient temperature of the intercalated graphite to 800°C at a heating rate of 25°C / min, and keep it for 1 hour, Then it was lowered to room temperature in an argon (300 mL / min) atmosphere, and the reaction product was collected to obtain graphene.

[0032] Adopt atomic force microscope (AFM) to observe 100 parts of graphenes prepared in this embodiment, the number of layers of graphene sheets prepared in this embodiment is 1~5 layers, wherein, the number of layers of 85% graphenes It is 1~3 layers.

Embodiment 3

[0034] A kind of preparation method of graphene, comprises the following steps:

[0035] (1) Mix 50g of graphite with a purity of 99.5% and 80g of 1-butyl-3-methylimidazole bistrifluoromethanesulfonimide salt, and use an ultrasonic machine with a power of 1000W to ultrasonicate the mixture for 48 Hour, obtain intercalated graphite;

[0036] (2) Place the above-mentioned intercalated graphite in a reactor with a helium (300mL / min) atmosphere, and raise the ambient temperature of the intercalated graphite to 700°C at a heating rate of 20°C / min, and keep it for 1 hour, Then it was lowered to room temperature in a helium (300 mL / min) atmosphere, and the reaction product was collected to obtain graphene.

[0037]Adopt atomic force microscope (AFM) to observe 100 parts of graphenes prepared in this embodiment, the number of layers of the graphene sheets prepared in this embodiment is 1~5 layers, wherein, the number of layers of 90% graphenes It is 1~3 layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com