Process for the production of aromatics from methanol conversion

A technology for methanol conversion and aromatic hydrocarbons, which can be applied in the production of bulk chemicals, chemical instruments and methods, and hydrocarbon production from oxygen-containing organic compounds, etc., and can solve the problems of low yield of aromatics and low yield of BTX.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Take by weighing 2.8g polyethylene glycol, 4.0g P123, 16g concentration be the nitric acid solution of 1mol / L, 3.9g aluminum nitrate, 27.9g tetraethyl orthosilicate and 28g water mix, dissolve under stirring condition, And continue to hydrolyze for 2h. Then it was transferred to an airtight container, gelled and aged for 24 hours at 65°C, and then the gel was taken out and dried to obtain sample A1.

[0025] 2) Weigh 7.0g sample A1, 0.3g HZSM-5 (SiO 2 / Al 2 o 3 Ratio=25) molecular sieve, 7.2g silica sol (SiO 2 Mass concentration 40%), 0.17g pseudo-boehmite, 0.3g scallop powder and 3.9g dilute hydrochloric acid solution (concentration is 1mol / L), after kneading evenly, adopt the mode of extrusion to make cylindrical particles, and obtain Sample B1.

[0026] 3) Take 1.5g of sample B1 and place it in the upper layer of the crystallization reaction kettle, place 4.0g of water and 1.0g of TPAOH in the lower layer, and crystallize at 160°C for 2 days under autogenous ...

Embodiment 2~6

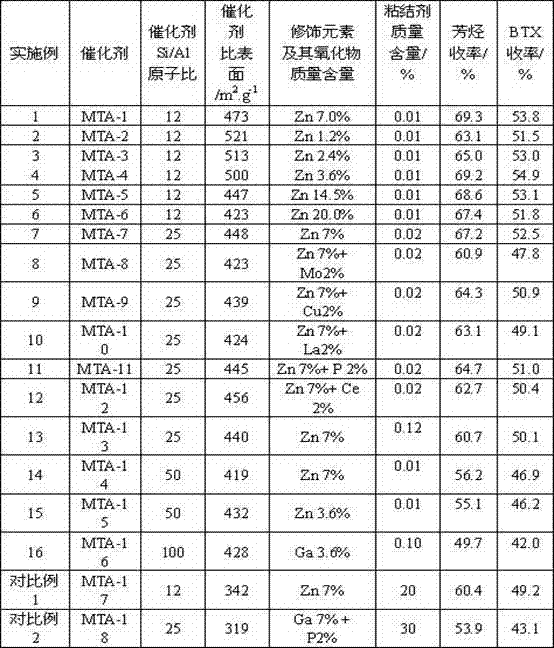

[0031] Weigh the sample C1 prepared in [Example 1], adjust the amount of zinc nitrate, and prepare catalysts with Zn oxide content of 1.2 parts, 2.4 parts, 3.6 parts, 14.5 parts and 20 parts respectively, which are denoted as MTA-2, MTA-3, MTA-4, MTA-5, MTA-6.

[0032] Catalyst evaluation adopts the method of [Example 1], and the results are listed in Table 1.

Embodiment 7

[0034] 1) Take by weighing 15.6g polyethylene oxide, 12g P123, 117g concentration be the hydrochloric acid solution of 1mol / L, 5.2g aluminum sulfate, 52.9g methyl orthosilicate and 110g water mix, dissolve under stirring condition, and sonicated for 10 minutes. Then it was transferred to an airtight container, and the gel was aged at 60°C for 36 hours, and then the gel was taken out and dried to obtain sample A2.

[0035] 2) Weigh 20g sample A2, 2g HZSM-5 (SiO 2 / Al 2 o 3 ratio=50) molecular sieve, 6g fumed silica, 1g pseudoboehmite, 5.5g silica sol (SiO 2 mass content 40%), 16g of dilute nitric acid solution with a concentration of 1.5%, kneaded uniformly, then formed by extruding, and dried to obtain sample B2.

[0036] 3) Take 5.0g of sample B4, absorb 1.0g of TPAOH and place it on the upper layer of the crystallization reaction kettle, place 10g of water on the lower layer, and crystallize at 170°C for 48 hours under autogenous pressure conditions. After the product is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com