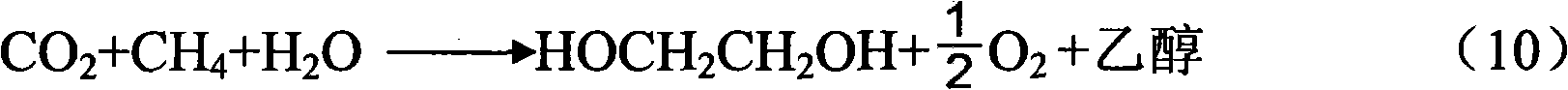

Method for preparing acetylene, ethylene, ethanol and ethylene glycol and coproducing hydrazine hydrate, benzene and derivatives of hydrazine hydrate and benzene by using CO or CO2

A technology of ethylene glycol and ethanol, which is applied in chemical instruments and methods, ether preparation, hydrocarbons, etc., and can solve problems such as carbon-carbon triple bond coupling that has not been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

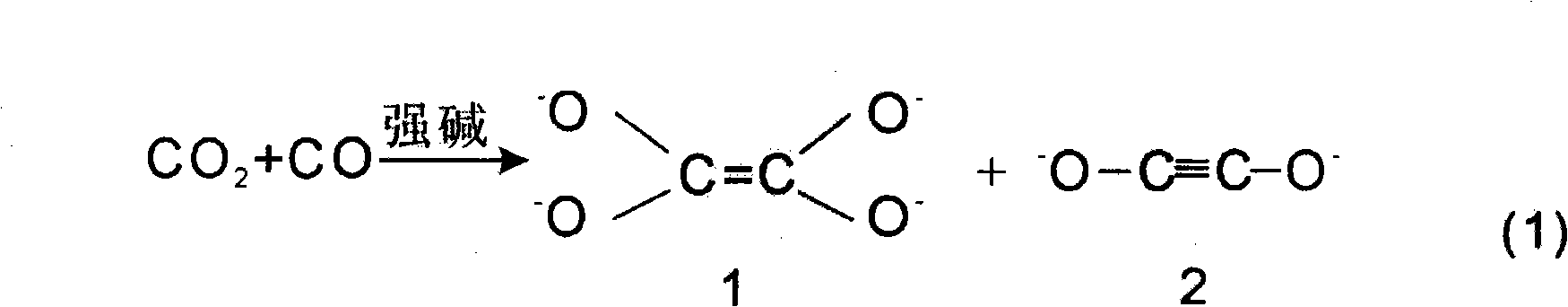

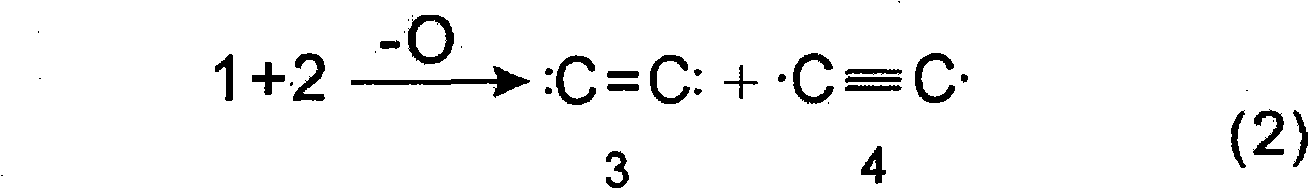

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Put 400g of 30% NaOH aqueous solution into the autoclave, start stirring, and slowly feed CO or its various flue gas at room temperature, or feed a mixture of equimolar CO and methane until the pressure of the reactor is 0.1-0.3MPa , keep warm for 5-50 minutes. The gas in the autoclave is collected as the acetylene product. The liquid phase in the autoclave is divided into two layers of oil and water, and the oil layer is separated into a mixture of benzene and its derivatives. The benzene product is separated by conventional distillation, and the conversion of CO and methane The yield is 98%, the yield of acetylene is 78%, and the yield of benzene and its derivatives is 19%.

Embodiment 2

[0056] Choose a conventional fixed-bed reactor with a diameter of 25mm. The fixed-bed filler is conventional calcium oxide or other super-alkaline solid catalyst particles. Use a pump to circulate 15% to 30% NaOH aqueous solution, and the liquid flows down from the top of the reactor. , come out from the bottom and return to the top, and use the external circulation cooling method to remove the heat. At room temperature, CO or its various flue gases or a mixture of equimolar CO and methane are slowly introduced from the bottom of the reactor. , the flow rate is controlled at 3-5g / min, and the acetylene gas flowing out from the top of the fixed-bed reactor is continuously collected by the conventional gas collection method, and the ventilation is stopped after 24 hours, and the oil-water liquid in the fixed-bed reactor is separated and separated The oil-out layer is a mixture of benzene and its derivatives. The conversion rate of CO and methane is 99%, the yield of acetylene is ...

Embodiment 3

[0058] Still select the fixed-bed reactor and packing thereof of the above-mentioned embodiment 2, but do not carry out external circulation with liquid NaOH. Directly feed a mixed gas of CO and methane from the bottom of the reactor at room temperature to a pressure of 0.1-0.3 MPa at the top of the reactor, and then use a gas flow pump to circulate the mixed gas for 1-24 hours to collect acetylene and ethylene at the top of the reactor. mixed gas, and recover the liquid benzene and its derivatives in the reactor. The conversion rate of CO and methane is 98%, the total yield of acetylene and ethylene is 86%, and the total yield of benzene and its derivatives is 12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com