Titanium alloy, polish sucker rod made of titanium alloy and application of polish sucker rod

A technology of oil pumping polished rods and titanium alloys, which is applied in the direction of drill pipes, drill pipes, casings, etc., can solve the problems of only 1 to 6 months of service life, affect the production efficiency of oil fields, and high production costs of oil production, and achieve comprehensive performance Prominence, weight reduction, high wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

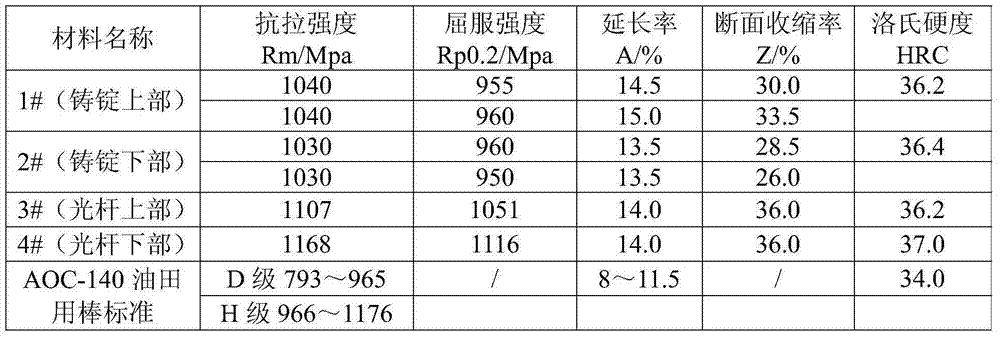

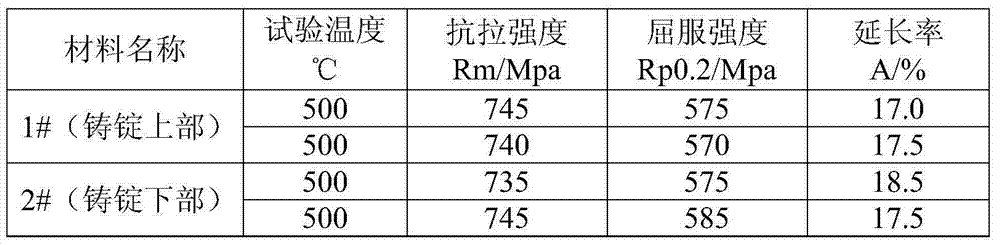

[0031] Grade 1 sponge titanium dried in an electric furnace at 150℃×2h, and Al-Mo alloy, Al-Si alloy, Al-V alloy, pure aluminum and pure zirconium chips, etc., are pressed into electrode blocks by a 2500t hydraulic press according to a certain ratio. Vacuum welding in the consumable electric arc furnace, smelting three times in the vacuum consumable electric arc furnace to form an ingot of Φ400×1500mm, and then peeling off the skin, removing the riser and the bottom on the lathe, the actual ingot size after lathing is Φ382×1450mm; Then take samples from the upper and lower parts of the ingot (the upper part is marked as 1#, and the lower part is marked as 2#) to detect the chemical composition and hardness; conduct ultrasonic flaw detection, size and surface quality inspection on the riser part of the ingot, and then polish the The ingot is heated by an electric furnace, free forged, and forged into a square bar. After being ground by a grinding wheel, the bar rolling machine i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com