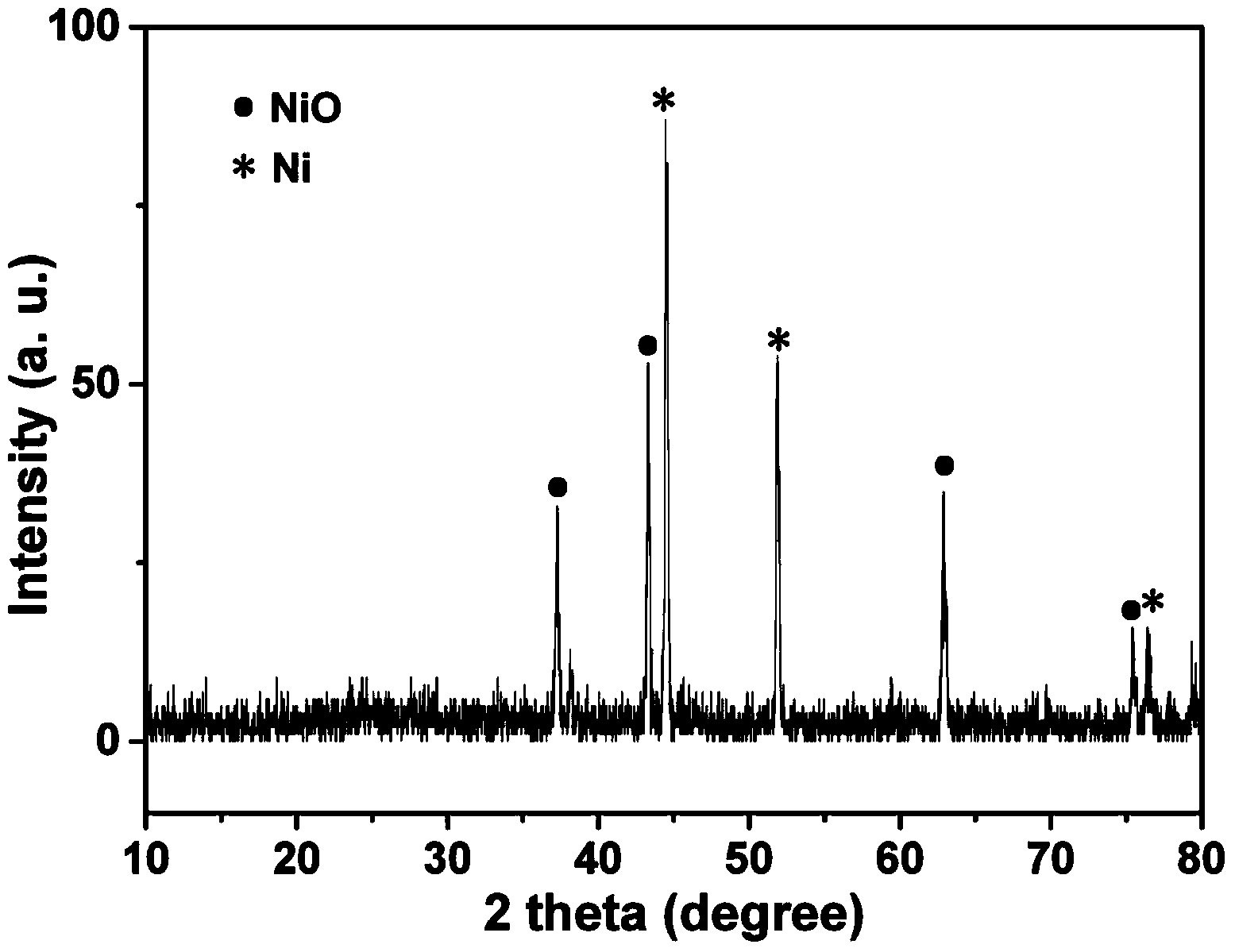

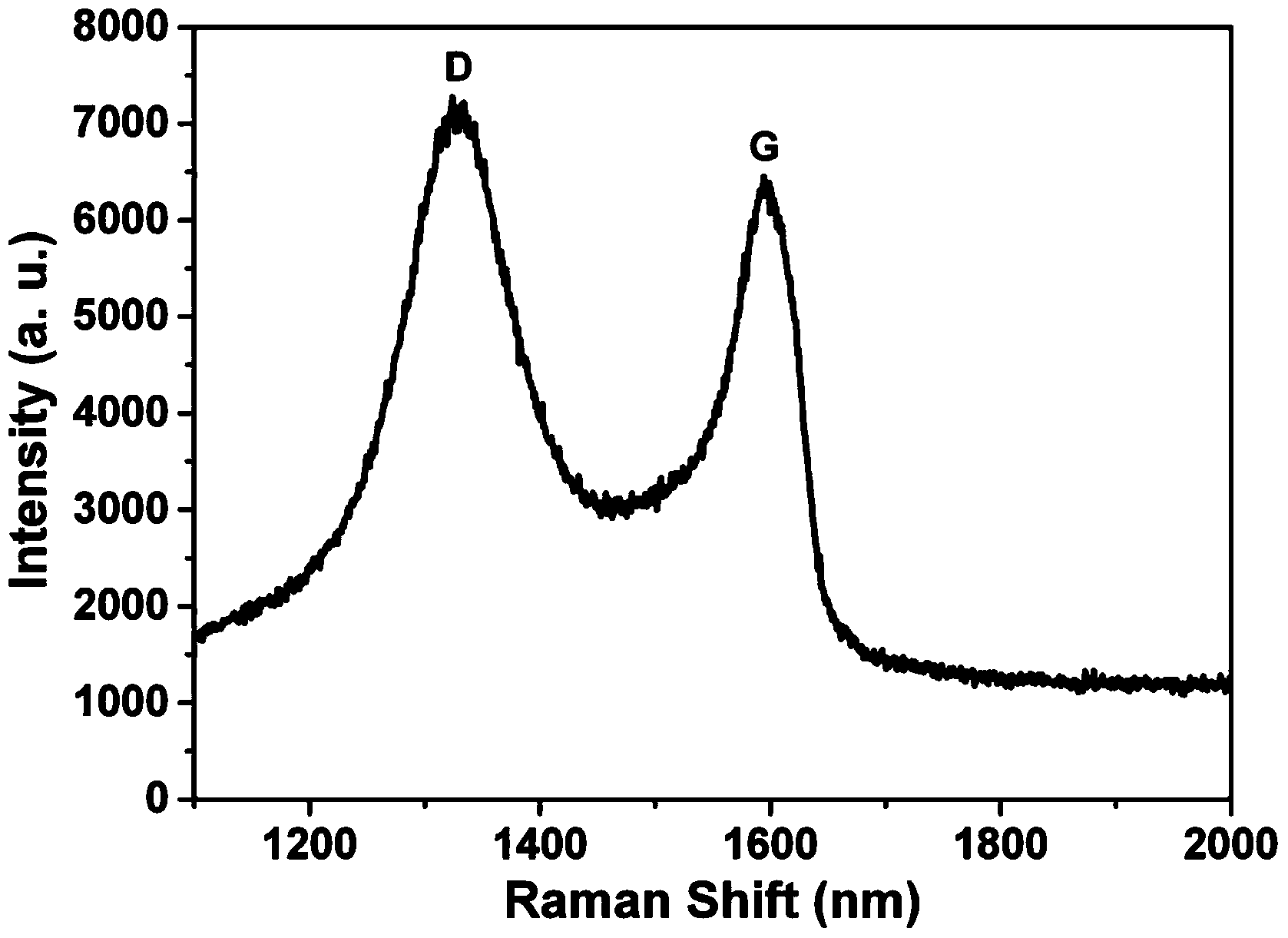

Method for manufacturing substrates of three-dimensional graphene-nickel oxide composite materials

A composite material and graphene technology, which is applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of low film uniformity, large performance impact, and easy agglomeration of materials, and achieves simple preparation methods, types and dosages. The effect of less and better electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 1.2g phenol into a flask, melt it at 43°C, add 4.2mL aqueous solution containing 0.6g formaldehyde after dissolving, then add 30mL 0.1M NaOH aqueous solution, stir for 10min, and put the mixed solution at 70°C The reaction was carried out for 0.5h to obtain a resole phenolic resin solution.

[0022] (2) Add 30 mL of an aqueous solution containing 1.92 g of block copolymer F127 to the above solution, stir at room temperature for 2 h, add 100 mL of water for dilution, and stir at 68 °C for 12 h.

[0023] (3) Clean the nickel foam with ethanol, acetone and water for 15 minutes, then let it dry naturally, then put it into a 100mL polytetrafluoroethylene reactor filled with 25mL of the solution prepared in the previous step, soak for 3h, then add 45mL After diluting with deionized water, the reaction kettle was put into a hydrothermal tank to perform hydrothermal reaction at 130° C. for 16 hours.

[0024] (4) Take out the nickel foam sheet and dry it in an oven at...

Embodiment 2

[0029] (1) Weigh 1.2g phenol into a flask, melt it at 43°C, add 4.2mL aqueous solution containing 0.6g formaldehyde after dissolving, then add 30mL 0.1M NaOH aqueous solution, stir for 10min, and put the mixed solution at 70°C The reaction was carried out for 0.5h to obtain a resole phenolic resin solution.

[0030] (2) Add 30 mL of an aqueous solution containing 1.92 g of block copolymer F127 to the above solution, stir at room temperature for 2 h, add 100 mL of water to dilute, and then stir at 72 °C for more than 10 h.

[0031] (3) Clean the nickel foam with ethanol, acetone and water for 15 minutes, then let it dry naturally, then put it into a 100mL polytetrafluoroethylene reactor containing 10mL of the solution prepared in the previous step, soak it for 3h, then add 60mL After diluting with deionized water, the reaction kettle was put into a hydrothermal tank to perform hydrothermal reaction at 130° C. for 16 hours.

[0032] (4) Take out the nickel foam sheet and dry it...

Embodiment 3

[0034] (1) Weigh 1.2g phenol into a flask, melt it at 43°C, add 4.2mL aqueous solution containing 0.6g formaldehyde after dissolving, then add 30mL 0.1M NaOH aqueous solution, stir for 10min, and put the mixed solution at 75°C The reaction was carried out for 0.5h to obtain a resole phenolic resin solution.

[0035] (2) Add 30 mL of an aqueous solution containing 1.92 g of block copolymer F127 to the above solution, stir at room temperature for 2 h, add 150 mL of water to dilute, and then stir at 68 °C for 12 h.

[0036] (3) Clean the nickel foam with ethanol, acetone and water for 15 minutes, then let it dry naturally, then put it into a 100mL polytetrafluoroethylene reactor filled with 25mL of the solution prepared in the previous step, soak for 3h, then add 45mL After diluting with deionized water, the reaction kettle was put into a hydrothermal tank to perform hydrothermal reaction at 130° C. for 16 hours.

[0037](4) Take out the nickel foam sheet and dry it in an oven a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com