Method for preparing cadmium telluride thin-film solar cell

A technology of solar cells and cadmium telluride, which is applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of high target cost, hindrance to application, unfavorable component production, etc., and achieve the effect of simplified process and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: A method for preparing cadmium telluride thin film solar cell

[0019] A method for preparing a cadmium telluride thin film solar cell, the battery structure of the cadmium telluride battery is: TCO / CdS / CdTe / contacted layer / metal electrode, TCO is a transparent conductive film, and its material is tin dioxide doped with fluorine , You can also use zinc oxide doped aluminum or indium tin oxide, etc. The material is required to have high light transmittance and conductivity, and it can be deposited by sputtering or chemical vapor reaction.

[0020] The window layer CdS can be deposited by chemical water bath method, near space sublimation method and magnetron sputtering method.

[0021] The absorbing layer cadmium telluride can be deposited by magnetron sputtering, near-space sublimation, evaporation, etc.

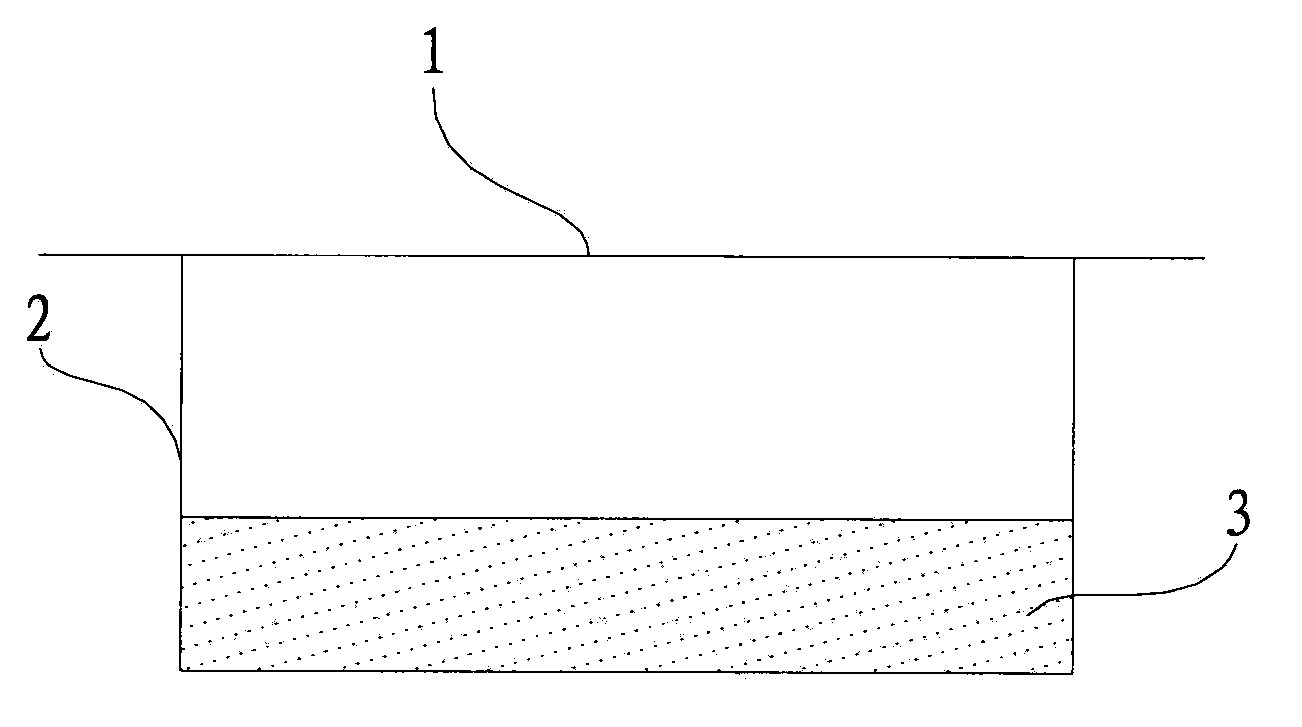

[0022] Next, the preparation of the contacted layer (also known as the transition layer) is carried out. The equipment used is as attached figure 1 Shown. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com