High-crystallinity titanium dioxide-silica nano composite material with regular mesoporous structure as well as preparation method and application thereof

A nanocomposite and mesoporous structure technology, applied in the field of physical chemistry, can solve problems such as specific surface area and pore volume decrease, pore wall collapse, affecting material structure and catalytic performance, etc., to reduce internal mass transfer resistance and increase contact probability , the effect of excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

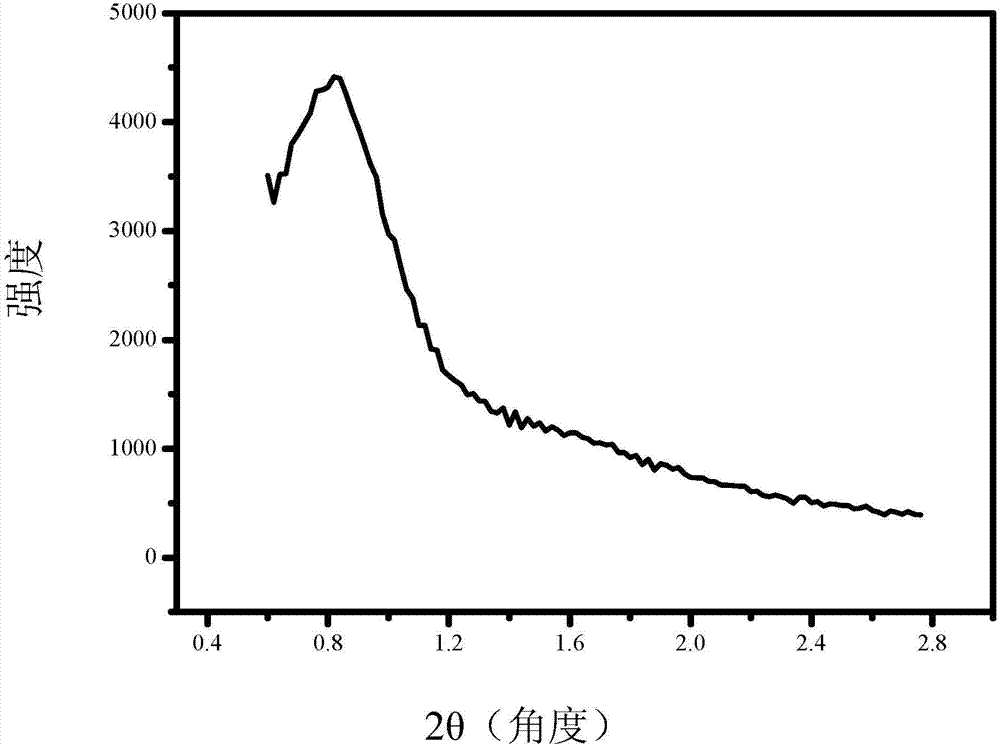

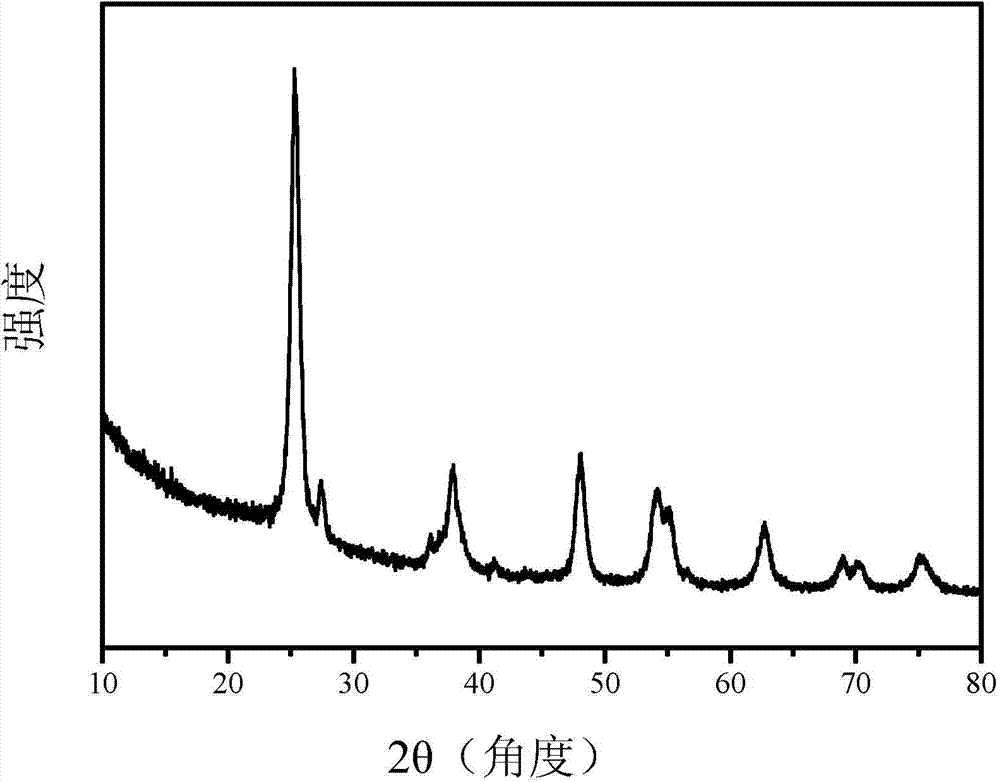

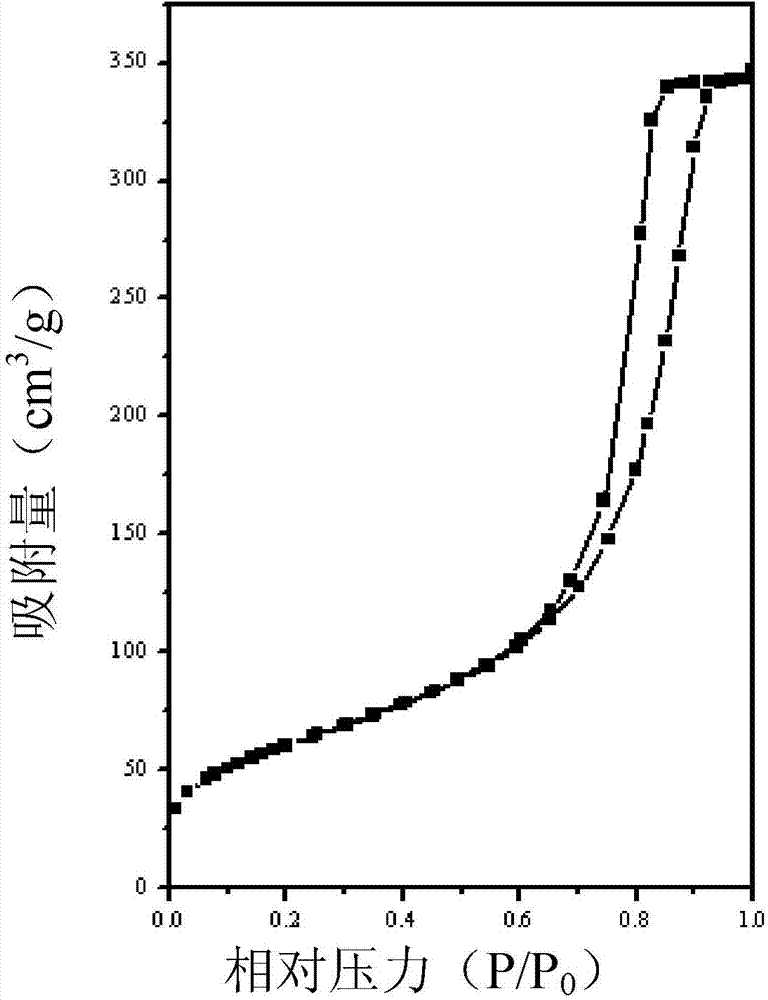

[0022] Example 1: Using F127 as a template to synthesize OM-SiO at 180°C 2 -TiO 2 Nanocomposites (OM stands for regular mesoporous, SiO 2 Silicon oxide, TiO 2 for titanium dioxide).

[0023] Add 1.0g of F127 to 38g of water to dissolve, then add 1.6ml of concentrated hydrochloric acid, add 1.15ml of ethyl orthosilicate after complete dissolution, add 4.2g of n-propyl titanate after reacting at 45°C for 6 hours, and continue to react for 24 hours to obtain a gel Put the reaction mixture into a stainless steel reaction kettle, heat it at 180°C for 24 hours, take out the reaction kettle, cool it, filter it with suction, wash it, and dry it to get the initial product, which has a high degree of crystallinity. The primary product is calcined under air conditions at 600°C to obtain a regular mesoporous silica-titania nanocomposite material with open pores and a specific surface area of 100m 2 / g, pore volume 0.15cm 3 / g, with a pore size of 15 nm.

Embodiment 2

[0024] Example 2: Using P123 as a template to synthesize OM-SiO at 180°C 2 -TiO 2 nanocomposites.

[0025] Add 1.2g of P123 to 38g of water to dissolve, then add 1.6ml of concentrated hydrochloric acid, add 1.15ml of ethyl orthosilicate after complete dissolution, add 4.2g of n-propyl titanate after reacting at 45°C for 6 hours, and continue to react for 24 hours to obtain a gel Put the reaction mixture into a stainless steel reaction kettle, heat it at 180°C for 24 hours, take out the reaction kettle, cool it, filter it with suction, wash it, and dry it to get the initial product, which has a high degree of crystallinity. The primary product is calcined under the air condition of 600°C to obtain a regular mesoporous silica-titania nanocomposite material with open channels.

Embodiment 3

[0026] Example 3: Using F127 as a template to synthesize OM-SiO at 220°C 2 -TiO 2 nanocomposites.

[0027]Add 1.0g of F127 to 38g of water to dissolve, then add 1.6ml of concentrated hydrochloric acid, add 1.15ml of ethyl orthosilicate after complete dissolution, add 4.2g of n-propyl titanate after reacting at 45°C for 6 hours, and continue to react for 24 hours to obtain a gel Put the reaction mixture into a stainless steel reaction kettle, heat it at 220°C for 24 hours, take out the reaction kettle, cool it, filter it with suction, wash it, and dry it to get the initial product, which has a high degree of crystallinity. The primary product is calcined under the air condition of 800°C to obtain a regular mesoporous silica-titania nanocomposite material with open pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com