A wear-resistant thermal shock-resistant composite material and its preparation method

A composite material, thermal shock resistance technology, applied in chemical instruments and methods, metal material coating technology, coating and other directions, can solve the problems of poor thermal shock resistance, brittle coating, etc., achieve excellent thermal shock resistance, Extended application range, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

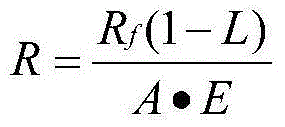

Method used

Image

Examples

example 1

[0021] 1: The addition amount of SiC whiskers is 20%, and the addition amount of A356 aluminum is 80%. The powder is uniformly ball-milled and then hot-pressed and sintered. The sintering temperature is 1800°C and the pressure is 39.2MPa. After heat preservation for 40 minutes, the block sample obtained by hot pressing was cut into regular rectangular parallelepiped samples and finely ground.

[0022] 2: Take an open container, fill it with a certain amount of water, add sodium nitrite and sodium carbonate, and make a concentration of 0.4% NaNO 2 and 0.2%Na 2 CO 3 Mix the solution, then add a certain amount of emulsifier (25% Ping Pingjia, 13% polyethylene glycol, 17% oleic acid, 45% triethanolamine), and finally make a mixed solution with a mass percentage concentration of emulsifier of 0.8%; After the solution is prepared, put the dried, cleaned and screened quartz sand (all passed through a 5-mesh sieve) in a bamboo basket, immerse it in the mixed solution, stir the aqueo...

Embodiment 1

[0025] The product obtained in Example 1 is at room temperature, and the surface of the coating is worn by a rotating friction grinding wheel for 1 min. The amount of wear of the surface coating material is extremely small, and the weight loss is less than 0.001g. Quickly transfer to the constant cooling for 1 hour and put it into the muffle furnace again. After several cycles, test its flexural strength and compare it with the flexural strength of the newly prepared material. It is found that after more than 20 cycles, the material is coated with The ply is largely intact, the flexural strength has dropped by about 25%, and the inner SiC aluminum matrix composite is intact.

example 2

[0027] 1: The addition of SiC whiskers is 20%, and the addition of A356 aluminum is 80%. The powder is uniformly ball-milled and then hot-pressed and sintered. The sintering temperature is 1800°C, the pressure is 39.2 MPa, and the heat preservation is 40 minutes. The block sample obtained by hot pressing is cut into regular cuboid samples and finely ground.

[0028] 2: Take an open container, fill it with a certain amount of water, add sodium nitrite and sodium carbonate, and make the concentration 0.4% NaNO 2 and 0.2%Na 2 C0 3 Mix the solution, then add a certain amount of emulsifier (25% Ping Pingjia, 13% polyethylene glycol, 17% oleic acid, 45% triethanolamine), and finally make a mixed solution with a mass percentage concentration of emulsifier of 0.8%; After the solution is prepared, put the dried, cleaned and screened quartz sand (all passed through a 5-mesh sieve) in a bamboo basket, immerse it in the mixed solution, and stir the aqueous solution. After the quartz san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com