Skin material of high-altitude aerostat and preparation method of skin material

A technology of skin materials and aerostats, which is applied in the field of aerospace materials, can solve the problems of isolation performance impact and difficult process control, etc., and achieve the effects of low helium gas permeability, difficult transfer, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

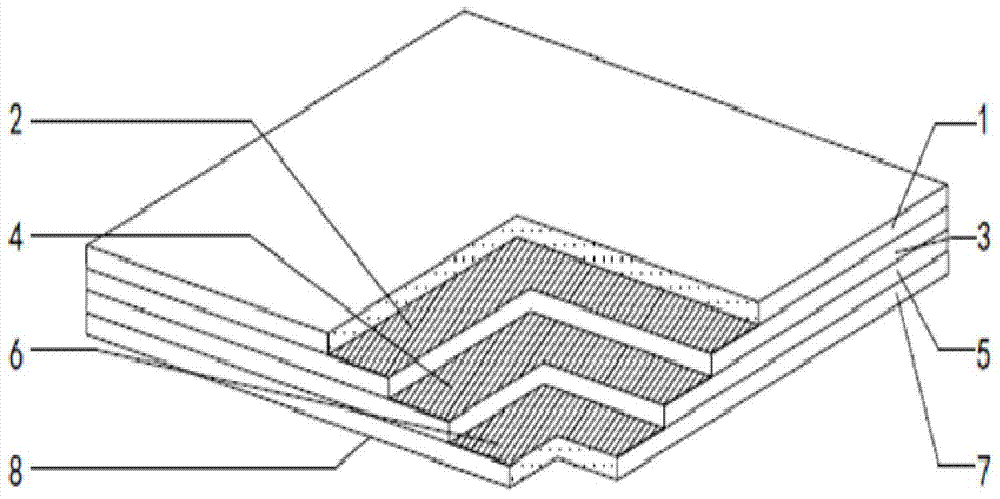

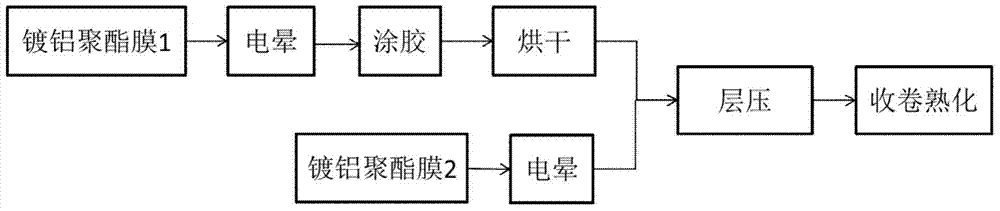

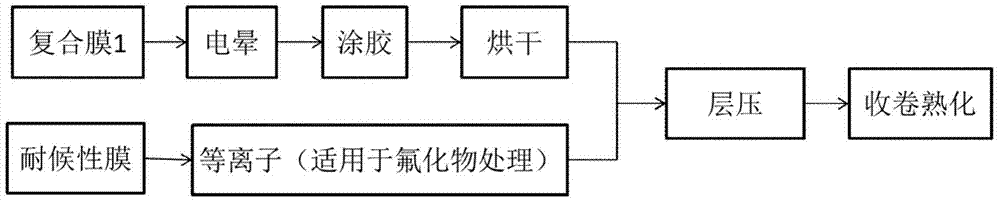

[0031] A specific embodiment of the skin material suitable for high-altitude aerostats provided by the present invention is that the weather-resistant layer, the barrier layer, the load-bearing layer and the welding adhesive layer (or welding layer for short) are glued together from the outside to the inside. It has the characteristics of high strength, light weight, low helium gas permeability and good weather resistance.

[0032] The weather-resistant layer of the high-altitude aerostat skin material is located on the outermost layer of the skin material to resist high-altitude strong ultraviolet radiation and ozone corrosion. The selected material is polyvinylidene fluoride (PVDF) film or ethylene-tetrafluoroethylene copolymer Polymer (ETFE) film has excellent weather resistance, wrinkle resistance, abrasion resistance, helium resistance and service life. The corona-treated film is used as a weather-resistant layer and is also easy to bond with other film layers.

[0033] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com