Method for separating tea pigment from instant tea slagging waste liquid

A technology for discharging slag waste liquid and tea pigment is applied in the field of separating tea pigment, which can solve problems such as waste water pollution and achieve the effect of solving waste water pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

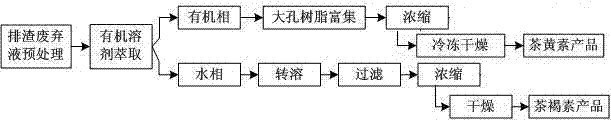

Image

Examples

Embodiment 1

[0034] The comprehensive utilization of Assam black tea slag discharge waste liquid has a solid mass fraction of 2.0% and a tea polyphenol mass concentration of 8.0 g / L. Measure 1000L of Assam black tea slag discharge waste liquid into the blending tank, add ascorbic acid to make the mass fraction 0.3%, fully dissolve, pump the slag discharge waste liquid through the heat exchanger, make the temperature of the feed liquid reach 65 °C, and then Filter through a 200-mesh sieve to remove impurities and obtain slag discharge waste liquid. Pump the slag discharge waste liquid into the mixing tank, add an equal volume of ethanol and ethyl acetate mixture (ethanol: ethyl acetate = 1:3), stir with oxygen for 10 minutes, let stand for a while, and wait for the upper and lower phases to separate Finally, the upper phase was collected as the organic phase, a total of 710L, and the lower phase was an aqueous phase, a total of 1080L. (1) Concentrate 710L organic phase by low-temperature v...

Embodiment 2

[0036]The comprehensive utilization of Yunnan CTC black broken tea slag discharge waste liquid has a solid content of 2.5% and a tea polyphenol mass concentration of 13.0g / L. Measure 1000L of Yunnan CTC black crushed tea slag discharge waste liquid into the blending tank, add ascorbic acid to make the mass fraction 0.3%, and after fully dissolving, pump the slag discharge waste liquid through a heat exchanger to make the temperature of the liquid reach 65°C. Filter through a 200-mesh sieve to remove impurities and obtain slag discharge waste liquid. Pump the slag discharge waste liquid into the mixing tank, add an equal volume of ethanol and ethyl acetate mixture (ethanol: ethyl acetate = 1:3), stir with oxygen for 10 minutes, let stand for a while, and wait for the upper and lower phases to separate Finally, collect the upper phase as the organic phase, 720L in total, and the lower phase as the aqueous phase, 1100L in total. (1) Concentrate 720L organic phase through low-tem...

Embodiment 3

[0040] The comprehensive utilization of Yunnan black tea slag discharge waste liquid has a solid mass fraction of 1.5% and a tea polyphenol mass concentration of 5.7g / L. Measure 1000L of black tea slag discharge waste liquid into the blending tank, add ascorbic acid to make the mass fraction 0.2%, fully dissolve, pump the slag discharge waste liquid through the heat exchanger, make the temperature of the liquid reach 60°C, and then pass through 200 mesh Sieve filter to remove impurities and obtain slag discharge waste liquid. Pump the slagging waste liquid into the mixing tank, add an equal volume of ethanol and ethyl acetate mixture (ethanol: ethyl acetate = 1:4), stir with oxygen for 10 minutes, let it stand for a while, and wait for the upper and lower phases to separate Finally, collect the upper phase as the organic phase, 730L in total, and the lower phase as the aqueous phase, 1150L in total. (1) Concentrate 730L organic phase by low-temperature vacuum at a concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com