A kind of preparation method of antibacterial type low surface energy modified polyurethane antifouling coating agent

An antifouling coating, low surface energy technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as poor compatibility and poor mechanical properties of polysiloxane, and achieve The method is simple, the wear resistance is good, and the film formation is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A kind of preparation method of antibacterial type low surface energy modified polyurethane antifouling coating agent of the present invention, comprises the following steps:

[0017] 1. Dissolve 0.5-1.5 parts by weight of initiator in 10-30 parts by weight of organic solvent, preheat to 55°C-95°C to obtain the first solution;

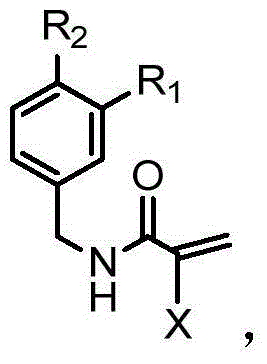

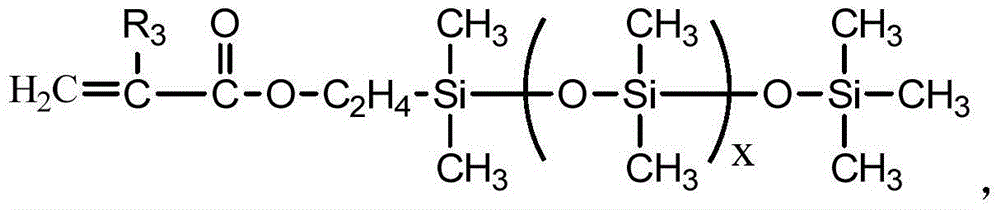

[0018] 2. Mix 10-50 parts by weight of monomers containing capsaicin functional groups, 10-50 parts by weight of polysiloxane-modified acrylates, 20-70 parts by weight of hydrocarbon chain acrylate monomers, 20-70 parts by weight of Acrylate monomer, 1.5-4.5 parts by weight of initiator and 0.5-6 parts by weight of chain transfer agent are dissolved in 20-90 parts by weight of organic solvent to obtain a second solution, which is slowly added dropwise to the first In the solution, the rate of addition is controlled to be 0.5-2mL / s; after adding, keep warm for 4-6 hours, add 0.5-1.5 parts by weight of initiator, raise the temperature to 65°C-105°...

Embodiment 1

[0035] (1) Dissolve 0.5g of 2,2’-azobisisobutyronitrile in 10g of butyl acetate and preheat to 55°C to obtain the first solution;

[0036] (2) 10g monomer containing capsaicin functional group , 10g polysiloxane modified acrylate , 20g methyl methacrylate, 20g hydroxyethyl methacrylate, 1.5g 2,2'-azobisisobutyronitrile and 0.5g dodecyl mercaptan were dissolved in 20g butyl acetate to obtain a second solution , slowly drop the second solution into the first solution, and control the dropping rate to 0.5mL / s; after the addition, keep warm for 4 hours, add 0.5g 2,2'-azobisisobutyronitrile, and raise the temperature to 105°C , kept for 4h to obtain a silicone-modified acrylate resin solution containing hydroxyl and capsaicin functional groups;

[0037] (3) Take the silicone-modified acrylate resin solution containing hydroxyl and capsaicin functional groups obtained in step (2), butyl acetate, polytetrafluoroethylene micropowder, and dibutyltin dilaurate in a weight ratio of 7...

Embodiment 2

[0039] (1) Dissolve 0.5g of 2,2’-azobisisobutyronitrile in 10g of ethylene glycol ethyl ether acetate, preheat to 55°C to obtain the first solution;

[0040] (2) 10g monomer containing capsaicin functional group , 30g polysiloxane modified acrylate , 20g methyl acrylate, 20g butyl acrylate, 40g hydroxyethyl acrylate, 3g 2,2'-azobisisobutyronitrile and 3g dodecyl mercaptan were dissolved in 60g ethylene glycol ethyl ether acetate to obtain the first For the second solution, slowly add the second solution dropwise to the first solution, and control the dropping rate to 1mL / s; after the addition, keep it warm for 6 hours, add 1g of 2,2'-azobisisobutyronitrile, and raise the temperature to 105°C , kept for 4h to obtain a silicone-modified acrylate resin solution containing hydroxyl and capsaicin functional groups;

[0041] (3) Take the silicone-modified acrylate resin solution containing hydroxyl and capsaicin functional groups obtained in step (2), ethylene glycol ether aceta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com