Method for integral preparation of products such as crocetin, genipin, gardenia blue and the like

A technology of saffron acid and genipin, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of difficulty in large-scale cultivation, high price and limited resources, etc. The effect of low equipment requirements, simple operation and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of crocetin.

[0036] (1) 200g of gardenia fruit was crushed and extracted twice with 1000ml of methanol. After removing the medicinal residues by filtration, the two extracts were combined and concentrated to 200ml.

[0037] (2) Add NaOH to the concentrated solution to adjust the pH to 10.0, and place it in an ultrasonic generator for reaction. The temperature of the reaction process was controlled at 28° C., the ultrasonic frequency was 40 kHz, the power was 100 W, and the reaction time was 10 minutes.

[0038] (3) After the reaction, the yellow-brown precipitate produced in the solution was collected by suction filtration.

[0039] (4) Take the yellow-brown precipitate and add 100 ml of alkaline water with a pH of 10. After it is completely dissolved, add 2 mol / L HCl aqueous solution to adjust the pH to 3. At this time, a large amount of brick-red precipitates are produced in the solution. The resulting brick-red precipitate was ...

Embodiment 2

[0044] Embodiment 2: Preparation of Genipin.

[0045] (1) Take 200 ml of the methanol filtrate obtained from the alkali hydrolysis reaction, evaporate the methanol to dryness, reconstitute with 200 ml of pure water, and add ethyl acetate at a volume ratio of 1:1 to construct a two-phase system.

[0046] (2) Add medium-temperature cellulase with an enzyme activity of 20wU (amount of 5%) into the two-phase system, and place it in an ultrasonic generator for reaction. The temperature during the reaction is controlled at 50°C, and the pH is adjusted to 4.5 with acetic acid. The frequency is 40kHz, the power is 100W, and the response time is 8 hours.

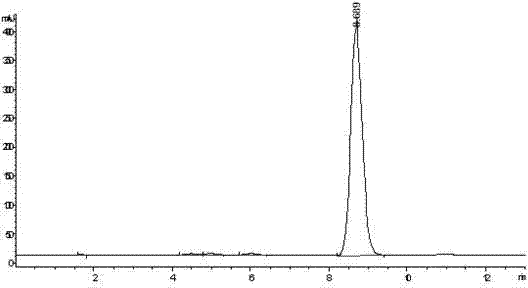

[0047] (3) The organic phase layer after the reaction was taken, washed 3 times with an equal volume of pure water, concentrated and evaporated to dryness to obtain 6.3 g of crude genipin with a purity of more than 75%.

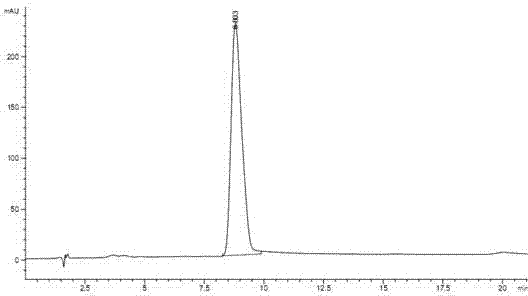

[0048] (4) Take 2.0 g of crude genipin, dissolve it in a methanol-water system at 50°C, put it in a re...

Embodiment 3

[0052] Embodiment 3: the preparation of gardenia blue pigment.

[0053] (1) Take 100.0 g of crude genipin (content 75%) and dissolve it in 10 L of distilled water.

[0054] (2) Add 200.0g of sodium glutamate with a purity of more than 99% to the aqueous solution, and place it in an ultrasonic generator for reaction. The temperature of the reaction process is controlled at 50°C, the ultrasonic frequency is 40kHz, the power is 100W, and the reaction time is 24 hours. After the reaction, the obtained solution is an aqueous solution of gardenia blue crude product, and the color value is E590>60.

[0055] (3) The crude gardenia blue aqueous solution after the reaction is intercepted and concentrated by using a hollow cellulose membrane with a cut-off pore size of 3000-5000 until the solid content in the retained solution exceeds 15%.

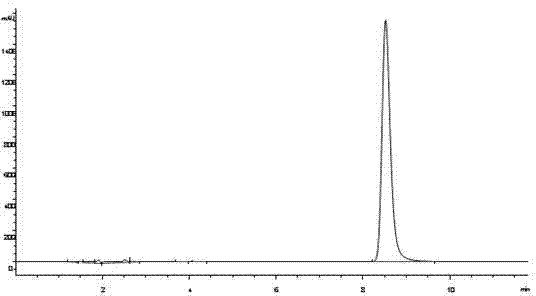

[0056] (4) The retentate was spray-dried to obtain 164.7 g of gardenia blue powder with color value E590>110. (Determination of color v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com