Graphene paper and preparation method and application thereof

A technology of graphene paper and graphite paper, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of reducing specific surface area capacitance performance, difficulty in large-scale preparation of graphene electrodes, etc., and achieve excellent capacitance performance , low cost, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) First prepare the mixed oxidant. Mix 40 mL of concentrated sulfuric acid and 10 mL of concentrated nitric acid in an ice bath, and keep stirring until homogeneous. Then slowly add 6g of potassium permanganate to the mixed solution, and continue to stir evenly.

[0036] (2) Cut the graphite paper with a thickness of 1 mm into 4*4 cm and a mass of 1.5 g, and put it into the mixed oxidant. Stirring was stopped and the whole was left at room temperature for 2 hours. The oxidized graphite paper was taken out, washed successively with hydrogen peroxide, 3 mol / L hydrochloric acid solution, and distilled water until neutral, and then freeze-dried.

[0037] (3) The dried graphene oxide paper was placed in a tube furnace, and calcined at a high temperature for 1 hour under a nitrogen atmosphere, and the calcining temperature was controlled at 800°C.

[0038] (4) Performance test:

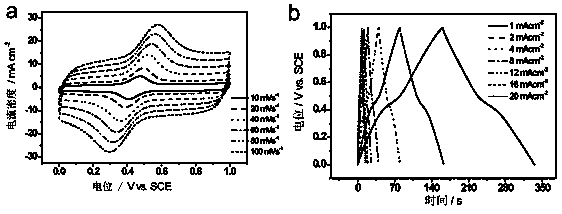

[0039] A, the prepared graphene paper has been carried out field emission scanning electron...

Embodiment 2~7

[0046] The preparation method of Examples 2-7 is different from that of Example 1 in the ratio of the mixed oxidant and the time and temperature of calcination. The proportioning of specific mixed oxidants, the time and temperature of calcination and the results of each embodiment are listed in Table 1 and Table 2.

[0047] Table 1. Oxidation regulation of graphite paper

[0048] Oxidant Sulfuric Amount Amount of oxidant nitric acid Potassium permanganate oxidation time Result description Specific surface area m 2 g -1 Conductivity Sm -1 Maximum specific capacitance mF cm -2 Example 2 35mL 10mL 5 g 2h The degree of graphene exfoliation is slightly lower 83 17 411 Example 3 45mL 15mL 7 g 2h Graphene has a high degree of peeling and is damaged 121 23 489 Example 4 35mL 15mL 6 g 2h The degree of graphene exfoliation is slightly lower 101 18 425 Example 5 45mL 10mL 6 g 2h Graphene has a hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com