Naproxen colon-specific drug-release micro pill and preparation method thereof

A colon positioning and naproxen technology, which is applied in sugar-coated pills, pharmaceutical formulations, antipyretics, etc., can solve the problems of poor reliability of time-dependent drug delivery systems, large individual differences in emptying time, etc., and achieve production process operation. Simple and feasible, easy to industrialize large-scale production, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

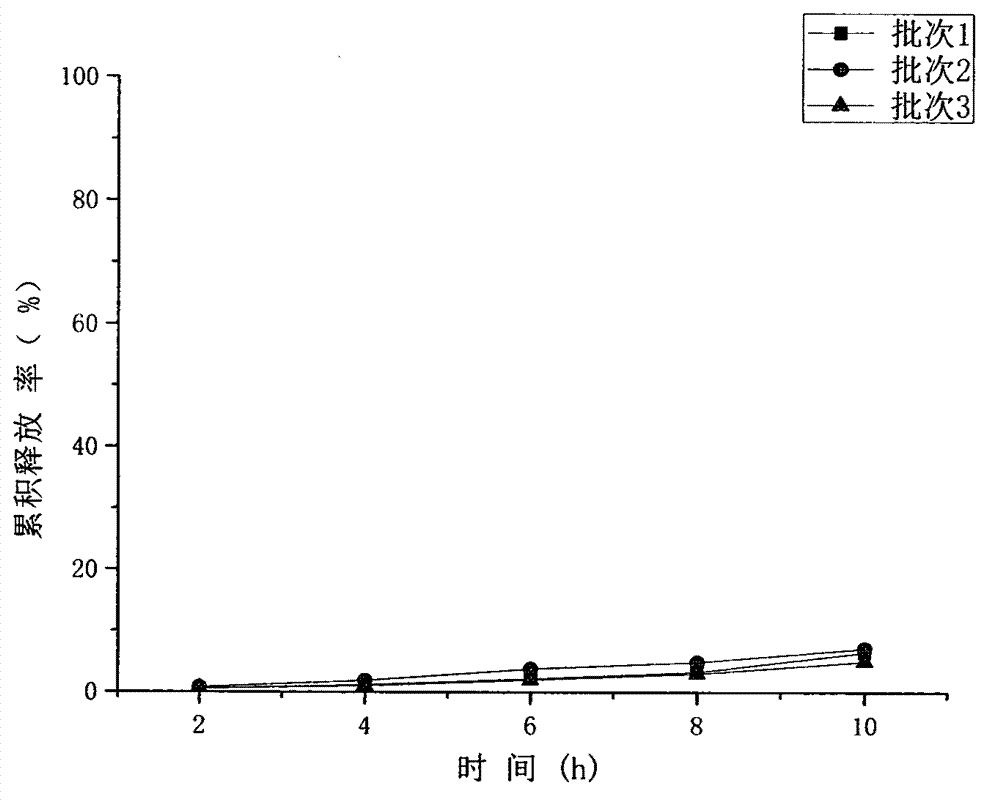

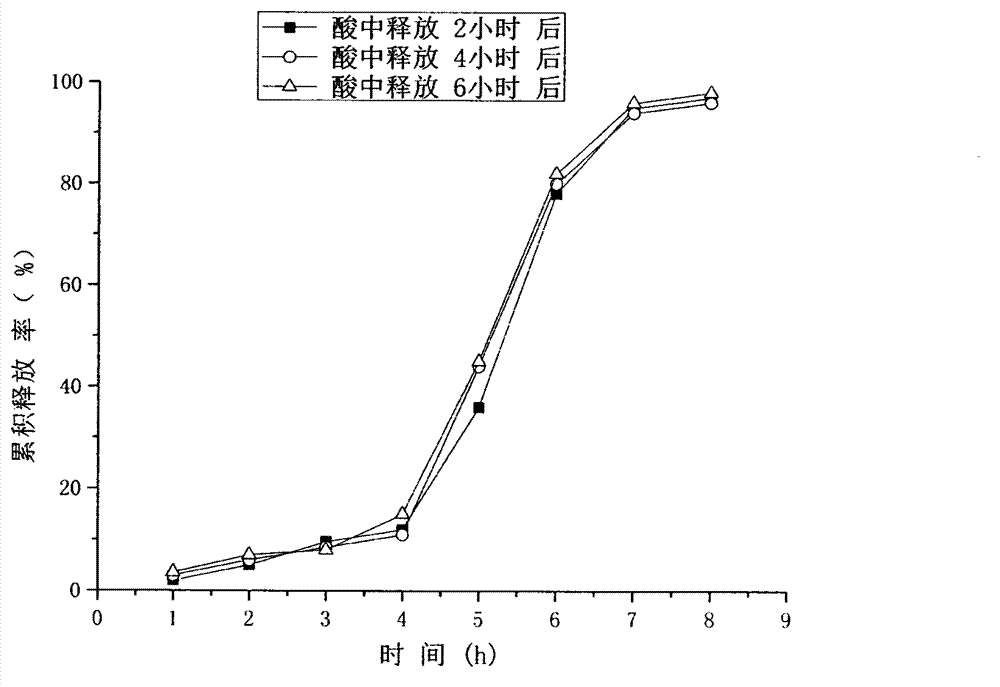

Embodiment 1

[0026] prescription:

[0027] Preparation of swelling layer coating solution: Weigh 1 g of hypromellose, add 70 mL of hot water (80° C.) to dissolve it, then add 5 g of croscarmellose sodium, disperse evenly, and add water to 100 mL.

[0028] Preparation of the coating solution for the controlled release layer: Take 50 mL of the ethyl cellulose aqueous dispersion coating solution (surelease), add 3 g of triethyl citrate, 1.5 g of magnesium stearate, homogenize with a homogenizer for 10 minutes, add water to 100mL.

[0029] Preparation of enteric layer coating solution: Take 6.25g of Eudragit L1000 and dissolve it in 80mL of 95% ethanol; take 1.25g of talcum powder and 0.63g of tributyl citrate, add appropriate amount of 95% ethanol, and homogenize with a homogenizer for 10 minutes. Then pour it into the solution of UTEK L100, add 95% ethanol to 100mL.

[0030] Fluidized bed preparation process parameters: coating temperature 35°C, blast frequency 27Hz, spray gun spray pressu...

Embodiment 2

[0033] prescription:

[0034] Preparation of swelling layer coating solution: Weigh 1g of hydroxypropyl cellulose, add 70mL of 95% ethanol to dissolve, then add 5g of croscarmellose sodium starch, after the dispersion is uniform, add 95% ethanol to 100mL.

[0035] Preparation of the coating solution for the controlled release layer: Take 50 mL of the ethylcellulose aqueous dispersion coating solution (aquacoat), add 3 g of dibutyl sebacate, 1.5 g of talcum powder, homogenize with a homogenizer for 10 minutes, add water to 100mL is ready.

[0036] Preparation of enteric layer coating solution: Take Eudragit L30D55 8.67g; take 0.88g of glyceryl monostearate, 801.08g of Tween and 1.76g of triethyl citrate, add appropriate amount of water, and homogenize with a homogenizer for 10 Minutes, then pour into the solution of UTEK L30D55, add water to 100mL.

[0037] Fluidized bed preparation process parameters: coating temperature 50°C, blast frequency 18Hz, spray gun spray pressure...

Embodiment 3

[0040] prescription:

[0041] Preparation of swelling layer coating solution: Weigh 1g of hydroxypropyl cellulose, add 70mL hot water (80°C) to dissolve, then add 5g of crospovidone and 0.5g of sodium lauryl sulfate, after the dispersion is uniform, add water to 100mL.

[0042] Preparation of the coating solution for the controlled release layer: Weigh 25 mL of the ethylcellulose aqueous dispersion coating solution (surelease), add 3 g of polyethylene glycol, 1.5 g of magnesium stearate, homogenize with a homogenizer for 10 minutes, add water to 100mL.

[0043] Preparation of enteric layer coating liquid: Take 29.33g of Eudragit L30D555; take 0.88g of magnesium stearate, 1.08g of sodium lauryl sulfate and 1.76g of triethyl citrate, add appropriate amount of water, and homogenize with a homogenizer Leave it for 10 minutes, then pour it into the solution of UTEK L30D55, and add water to 100mL.

[0044] Fluidized bed preparation process parameters: coating temperature 45°C, bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com