Iron/chitosan/polyoxyethylene composite nanofiber membrane arsenic removal material and electrostatic spinning preparation method thereof

A composite nanofiber, polyethylene oxide technology, applied in chemical instruments and methods, alkali metal compounds, water/sludge/sewage treatment, etc., to achieve the effects of strong acid and alkali resistance, low cost, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

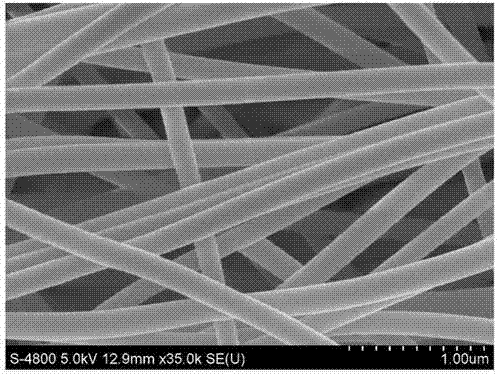

Image

Examples

Embodiment 1

[0016] 1) Preparation of spinning solution: Dissolve 2.5 g chitosan into 50 mL acetic acid solution with a volume fraction of 50%, stir magnetically until dissolved to obtain a 5% w / v chitosan solution? 3% w / v chitosan solution obtained by the same method vPolyethylene oxide solution? Weigh 6.0g polyoxyethylene solution and add it to the chitosan solution, and stir magnetically to obtain a mixed polymer solution in which chitosan accounts for 93% of the solute.

[0017] 2) Doping: 0.24 g FeCl 3 Add to step 1) mixed polymer solution, magnetically stir until FeCl 3 dissolved to obtain an electrospinning solution in which the iron element accounts for 3% of the mass percentage of the solute.

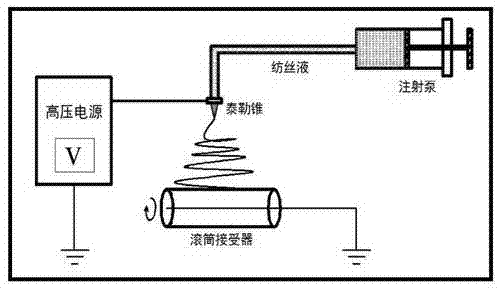

[0018] 3) Preparation of electrospun membrane: Dissolve the electrospun membrane in step 2) into a 10 m1 syringe, set the spinning parameters: voltage 15 kV, spinneret inner diameter 0.6 mm, spinning solution flow rate 0.9 mL / h, the distance from the spinneret to the receiving drum is 15...

Embodiment 2

[0022] 1) Preparation of spinning solution: Dissolve 2.5 g chitosan into 50 mL acetic acid solution with a volume fraction of 50%, stir magnetically until dissolved to obtain a 5% w / v chitosan solution? 3% w / v chitosan solution obtained by the same method vPolyethylene oxide solution? Weigh 6.0g polyoxyethylene solution and add it to the chitosan solution, and stir magnetically to obtain a mixed polymer solution in which chitosan accounts for 93% of the solute.

[0023] 2) Doping: 0.54 g FeCl 3 Add to step 1) mixed polymer solution, magnetically stir until FeCl 3 dissolved to obtain an electrospinning solution in which the iron element accounts for 6% by mass of the solute.

[0024] 3) Preparation of electrospun membrane: Dissolve the electrospun membrane in step 2) into a 10 m1 syringe, set the spinning parameters: voltage 15 kV, spinneret inner diameter 0.6 mm, spinning solution flow rate 0.9 mL / h, the distance from the spinneret to the receiving drum is 15 cm, the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com