Preparation method of bismuth oxycarbonate flower-like microsphere thermally synthesized by ethylene glycol-water mixed solvent

A technology of bismuth oxycarbonate flowers and mixed solvents, which is applied in the field of preparation of inorganic micro-nano materials, and achieves the effects of high product yield, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

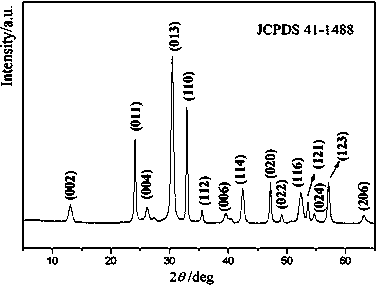

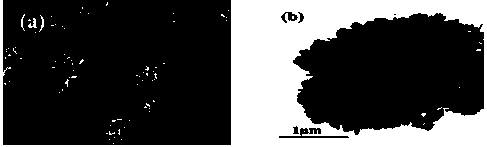

[0018] Mix 48ml of ethylene glycol and 12ml of deionized water evenly to form a mixed solvent, then add 2mmol of bismuth nitrate and 0.5g of urea successively under stirring, and stir until completely dissolved. The final solution was transferred to a 100 ml polytetrafluoroethylene-lined stainless steel reaction vessel. Put it in a dry box, and conduct a hydrothermal reaction at 180° C. for 12 hours. Then it was naturally cooled to room temperature, and the obtained precipitate was rinsed three times with deionized water and absolute ethanol, separated by centrifugation, and dried in a vacuum oven at 80° C. for 12 hours. Bismuth oxycarbonate flower-like microspheres can be obtained. The X-ray diffraction pattern of the bismuth oxycarbonate product is shown in figure 1 , the position and intensity of each diffraction peak in the figure are consistent with the standard diffraction card (JCPDS41-1488). Its scanning electron microscope picture is shown in figure 2 a, TEM imag...

Embodiment 2

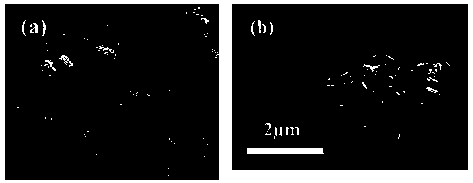

[0020] Mix 48ml of ethylene glycol and 12ml of deionized water evenly to form a mixed solvent, then add 2mmol of bismuth nitrate and 0.5g of urea successively under stirring, and stir until completely dissolved. The final solution was transferred to a 100 ml polytetrafluoroethylene-lined stainless steel reaction vessel. Place it in a dry box, and conduct a hydrothermal reaction at 100° C. for 12 hours. Then it was naturally cooled to room temperature, and the obtained precipitate was rinsed three times with deionized water and absolute ethanol, separated by centrifugation, and dried in a vacuum oven at 80° C. for 12 hours. Bismuth oxycarbonate flower-like microspheres can be obtained. The scanning electron microscope picture of the bismuth oxycarbonate product is shown in image 3 a and 3b, show the bismuth oxycarbonate product as flower-like microspheres.

Embodiment 3

[0022] Mix 48ml of ethylene glycol and 12ml of deionized water evenly to form a mixed solvent, then add 2mmol of bismuth nitrate and 0.5g of urea successively under stirring, and stir until completely dissolved. The final solution was transferred to a 100 ml polytetrafluoroethylene-lined stainless steel reaction vessel. Place it in a dry box, and conduct a hydrothermal reaction at 180° C. for 6 hours. Then it was naturally cooled to room temperature, and the obtained precipitate was rinsed three times with deionized water and absolute ethanol, separated by centrifugation, and dried in a vacuum oven at 80° C. for 12 hours. Bismuth oxycarbonate flower-like microspheres can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com