New technology of synthesizing dimethyldichlorosilance

A technology of dimethyldichlorosilane and methyltrichlorosilane, applied in the field of synthesizing dimethyldichlorosilane, can solve the problems of difficult large-scale utilization, direct discharge or incineration, immature technology, etc., and achieve production efficiency Improved, reduced emissions, simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

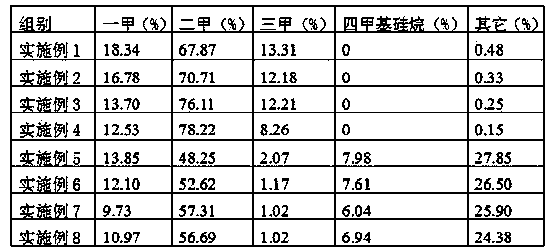

[0034] Add methyltrichlorosilane and trimethylchlorosilane to the raw material tank, and feed them to the preheating section of the fixed bed reactor with nitrogen gas. The temperature in the preheating section is 150°C. After the raw materials are vaporized, they enter the fixed bed reaction section with a diameter of φ25mm , the reaction section is filled with AlCl 3 Immobilized γ-Al 2 o 3 Immobilized catalyst, the temperature of the reaction section is 250°C, the reaction pressure (gauge pressure) is 0 Mpa; the residence time is 40s, the product after the reaction is cooled by the condenser, collected, sampled, analyzed and weighed, and a small amount of tail gas is absorbed with alkali solution. The samples were analyzed by gas chromatography, and the data are shown in Table 1.

[0035] The molar ratio of methyltrichlorosilane to trimethylchlorosilane is methyltrichlorosilane:trimethylchlorosilane=1:1;

[0036] The AlCl 3 Immobilized γ-Al 2 o 3 The dosage of the immo...

Embodiment 2

[0038] Add methyltrichlorosilane and trimethylchlorosilane to the raw material tank, and feed them to the preheating section of the fixed bed reactor with nitrogen gas. The temperature in the preheating section is 150°C. After the raw materials are vaporized, they enter the fixed bed reaction section with a diameter of φ25mm , the reaction section is filled with AlCl 3 Immobilized γ-Al 2 o 3 Immobilized catalyst, the temperature of the reaction section is 300°C, the reaction pressure (gauge pressure) is 0.6 Mpa; the residence time is 30s, the product after the reaction is cooled by the condenser, collected, sampled, analyzed and weighed, and a small amount of tail gas is absorbed with alkali solution. The samples were analyzed by gas chromatography, and the data are shown in Table 1.

[0039] The molar ratio of methyltrichlorosilane to trimethylchlorosilane is methyltrichlorosilane:trimethylchlorosilane=1.5:1;

[0040] The AlCl 3 Immobilized γ-Al 2 o 3 The dosage of the ...

Embodiment 3

[0042]Add methyltrichlorosilane and trimethylchlorosilane or methyltrichlorosilane and low boilers into the raw material tank, and at the same time add the mixture of zinc chloride and tin chloride, and feed it to the fixed-bed reactor with nitrogen to preheat Section, all the other are with embodiment 2;

[0043] The mass ratio of each component in the mixture of zinc chloride and tin chloride is zinc chloride:tin chloride=1.15:1, and the amount of the mixture of zinc chloride and tin chloride is methyltrichlorosilane and 10ppm of the total amount of trimethylchlorosilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com