A high temperature resistant oil flame retardant chlorinated polyethylene heat shrinkable sleeve and its preparation method and application

A chlorinated polyethylene and heat-shrinkable sleeve technology is applied in the field of high temperature resistant oil flame retardant chlorinated polyethylene (CPE) heat-shrinkable sleeve and its preparation, which can solve problems such as unseen research contents, and achieve cost reduction and guarantee The effect of processing thermal stability and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

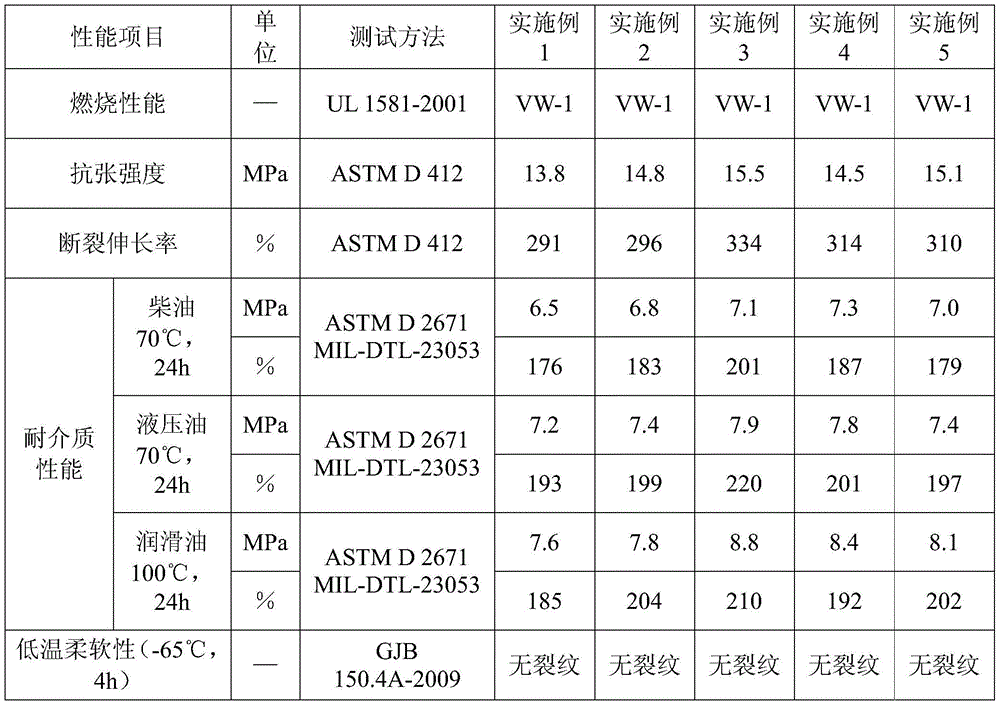

Examples

Embodiment 1

[0062] (1) Take 7kg of antimony trioxide, 2kg of flame retardant synergist (FRP-33, Guangzhou Qiyuan Chemical Co., Ltd., the same as the following examples), 65kg of magnesium hydroxide, 20kg of melamine cyanurate and hydrotalcite Put 0.5kg into the mixing room of the single-screw banburying granulator in turn, banbury at 90°C for 6min, then add chlorinated polyethylene (CPE, the mass content of chlorine is 35%), Weifang Jinyida Plastic Co., Ltd. The brand is CPE135A, the following examples are the same) 50kg, linear low density polyethylene (LLDPE, Saudi Basic Industries Corporation, the brand is 218-W, the melt index is 2g / 10min, and the density is 0.918g / cm 3 , the following examples are the same) 10kg, ethylene-vinyl acetate copolymer (EVA, the content of vinyl acetate accounts for 14% by mass, the melt index is 3.5g / l0min, Japan Mitsui Group, the brand is P1405, the following examples are the same) 16kg, ethylene-octene copolymer (POE, ExxonMobil, grade vistamaxx6102, mas...

Embodiment 2

[0067] (1) Put 20kg of antimony trioxide, 8kg of flame retardant synergist FRP-33, 70kg of magnesium hydroxide, 15kg of melamine pyrophosphate and 2kg of hydrotalcite into the mixing room of the single-screw banburying granulator in sequence at 90 Mix at ℃ for 5 minutes, then add chlorinated polyethylene 70kg, acrylic rubber (DuPont, the brand is VamacG, Mooney viscosity ML100℃1+4 is 16.5MU (ASTMD1646), the following examples are the same) 5kg, ethylene-acetic acid Vinyl ester copolymer 30kg, ethylene-ethyl acrylate copolymer (EEA, DuPont, brand name Elvaloy2116, mass content of ethyl acrylate is 16%, melt index is 1.0g / 10min (ASTMD1238)) 5kg, 7kg polymer phase Compatibility agent Polybond3149, 5kg black mother BLACKII, zinc stearate 1.5kg, calcium stearate 1.5kg, 0.7kg antioxidant 1010, 0.4kg antioxidant TH412S, 1kg antioxidant 445, 0.4kg antioxidant 697 and 1.5kg of silicone additive TEGOMERH-Si6440P, banburying at 105°C for 6min, then adding 1.5kg of triallyl isocyanate and...

Embodiment 3

[0071] (1) Put 25kg of antimony trioxide, 12kg of flame retardant synergist FRP-33, 30kg of magnesium hydroxide and 3kg of hydrotalcite into the mixing room of the single-screw internal mixing granulator in sequence, and banbury at 80°C for 4 minutes, Then add 65kg of chlorinated polyethylene, 25kg of ethylene-vinyl acetate copolymer, EPDM (EPDM, Jilin Petrochemical, brand J-4045) 5kg, 6kg of polymer compatibilizer Polybond3149, 6kg of black mother BLACKII, Zinc stearate 0.5kg, magnesium stearate 0.5kg, 1kg antioxidant 1010, 1kg antioxidant TH412S, 1.5kg antioxidant 445, 0.5kg antioxidant 697 and 1kg silicone additive TEGOMERH-Si6440P at 90 Mix at ℃ for 5 minutes, then add 2kg of triallyl isocyanate and knead at 90℃ for 6 minutes, automatically feed the above mixture to the granulation part of the single-screw mixer granulator, extrude at 90-120℃, Wire drawing, air cooling, dicing;

[0072] (2) Extrude the above-mentioned granulated pellets into a tube with a screw extruder e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com