Thermoplastic polyester elastomer heat-shrinkable sleeve for automobile wiring harness, preparation method and application

A thermoplastic polyester and automotive wiring harness technology, applied in the field of heat-shrinkable sleeves, can solve the problems of mechanical properties, poor oil resistance, acid and alkali corrosion resistance, high cost of fluoropolymer materials, poor mechanical strength of silicone rubber, etc., and achieve low cost. Environmental protection, excellent mechanical properties, strong high temperature diesel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

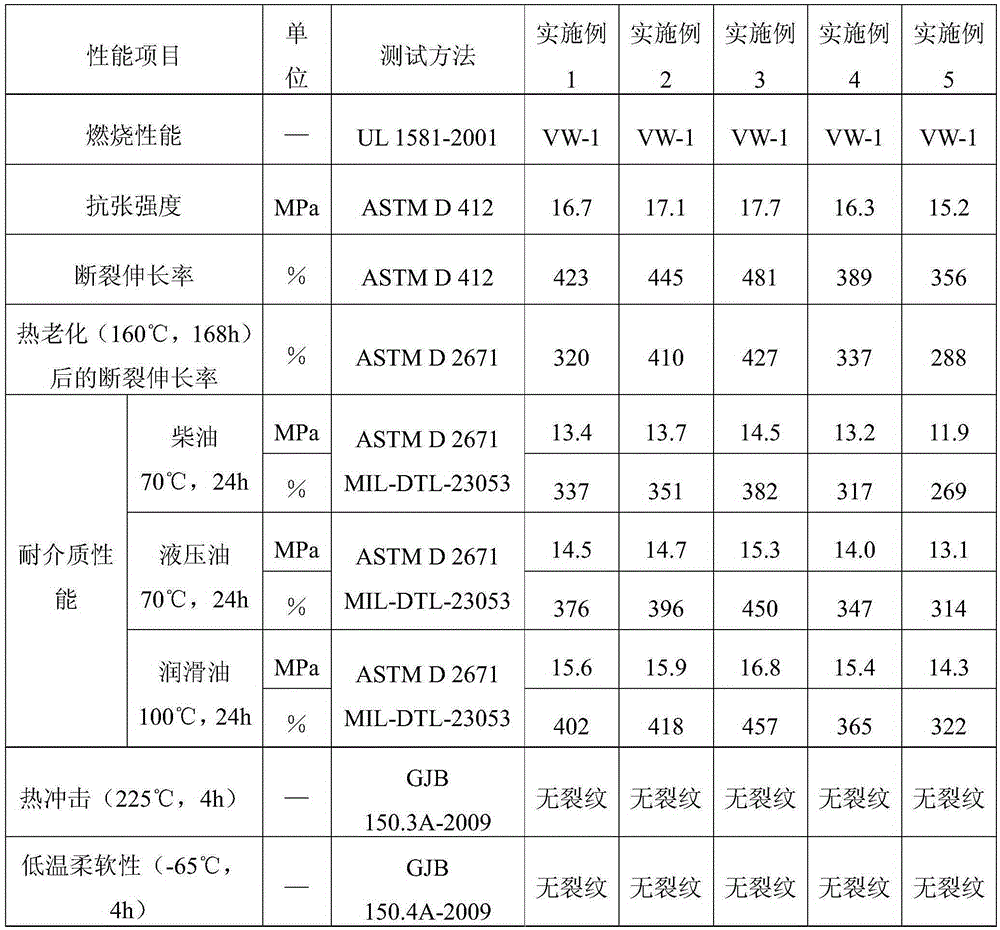

Examples

Embodiment 1

[0046] (1) Take 50kg of thermoplastic polyester elastomer (TPEE, Shore hardness 46D, Japan Toyobo, the brand is PelpreneX-146D, the same as the following examples), fluorine rubber (DuPont, USA, the brand is VITONA-HV, the same as the following examples) ) 30kg, black masterbatch (Cabot of the United States, the brand is PLASBLAKUN2014, the same as the following examples) 5kg, antimony trioxide 5kg, magnesium hydroxide 50kg, flame retardant synergist (brand is FRP-33, Guangzhou Qiyuan Chemical Co., Ltd. Company, the following examples are the same) 3kg, hydrotalcite 0.5kg, zinc stearate 0.5kg, 0.1kg antioxidant 1010, 0.15kg antioxidant TH-24, 0.2kg antioxidant 445, 0.05kg antioxidant 697 Put 0.5kg of polyester graft modified silicone additive (Shanghai Daile, brand: TEGOMERH-Si6440P, the same as in the following examples) into the mixing chamber of the single-screw internal mixing granulator in sequence, and banbury at 180°C for 15min , then add 1 kg of triallyl isocyanate and...

Embodiment 2

[0050] (1) Take 80kg of thermoplastic polyester elastomer X-146D, 60kg of fluororubber VITONA-HV, 15kg of black mother PLASBLAKUN2014, 30kg of antimony trioxide, 15kg of magnesium hydroxide, 15kg of aluminum hydroxide, 10kg and 15kg of melamine cyanurate Flame retardant synergist FRP-33, hydrotalcite 2kg, zinc stearate 1kg, calcium stearate 1kg, 1kg antioxidant 1010, 1.2kg antioxidant TH-24, 1.2kg antioxidant 445, 0.6kg antioxidant Oxygen agent 697 and 2kg of silicone additive TEGOMERH-Si6440P were sequentially put into the mixing chamber of the single-screw banburying granulator, banburying at 180°C for 15min, then adding 2.5kg of triallyl isocyanate and banburying at 180°C for 5min , the above-mentioned mixture is automatically fed to the granulation part of the single-screw banbury granulator, extruded, drawn, air-cooled, and granulated at 130-220 °C;

[0051] (2) Extrude the above-mentioned granulated pellets into a tube with a screw extruder equipped with a die and a mand...

Embodiment 3

[0054] (1) Take 60kg of thermoplastic polyester elastomer X-146D, 50kg of fluororubber VITONA-HV, 10kg of black mother PLASBLAKUN2014, 30kg of antimony trioxide, 10kg of flame retardant synergist FRP-33, 2kg of hydrotalcite, zinc stearate 1kg, 0.4kg of antioxidant 1010, 0.7kg of antioxidant 618, 0.7kg of antioxidant 445, 0.2kg of antioxidant 697 and 1kg of silicone additive TEGOMERH-Si6440P were put into the mixing material of the single-screw internal mixing granulator in turn Mix in the chamber at 180°C for 15 minutes, then add 1.5kg of pentaerythritol tetraacrylate and banbury for 5 minutes at 180°C, automatically feed the above mixture to the granulation part of the single-screw banburying granulator, at 130-220°C Down extrusion, wire drawing, air cooling, pelletizing;

[0055] (2) Extrude the above-mentioned pelletized pellets into a tube with a screw extruder equipped with a die and a mandrel at 130-220°C, and then irradiate with an electron accelerator. After cross-lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com