Preparation method of high-activity SnO2-TiO2 composite nanometer photocatalyst

A nano-photocatalyst and high-activity technology, applied in the field of nano-materials and photocatalysis, can solve the problems of unstable catalyst activity, limited scope of use, and limited scope of use, achieve short reaction period, increase the number of surface oxygen holes, and facilitate the The effect of light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

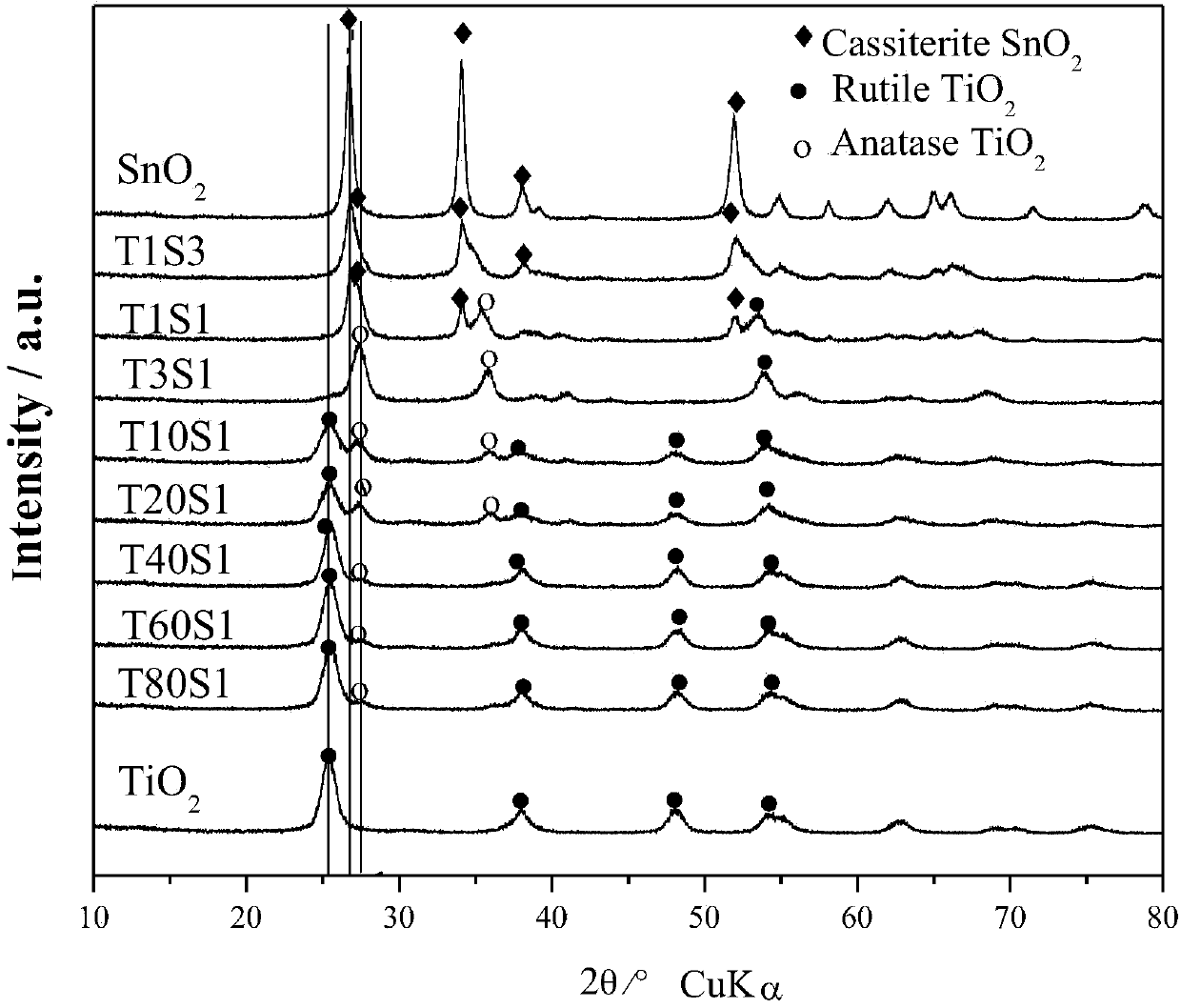

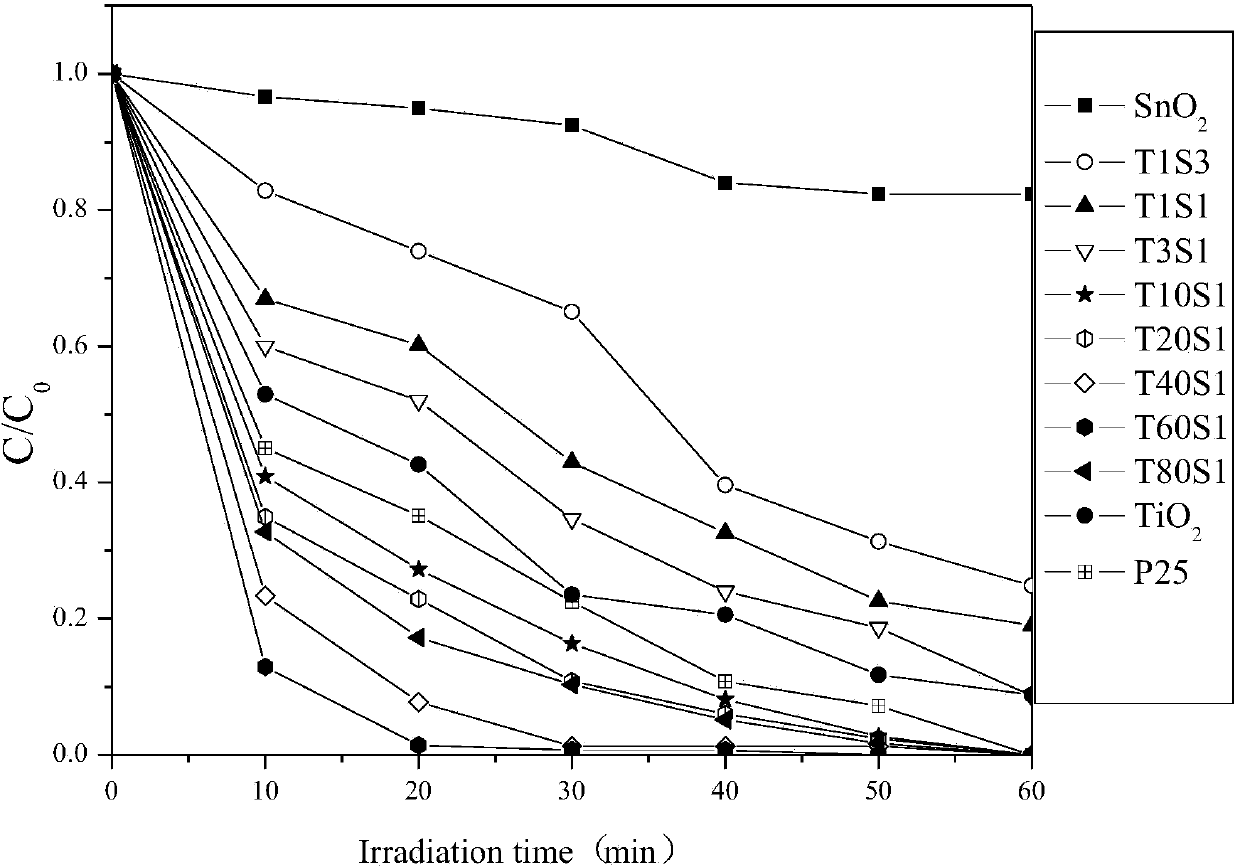

[0034]Mix 60ml of tetra-n-butyl titanate, 255ml of absolute ethanol, and 30ml of glacial acetic acid evenly, and add 30ml of dilute nitric acid (nitric acid: water = 1:10) drop by drop under constant stirring to adjust the pH to 3, and continue stirring for 15 minutes. , add 30ml of deionized water, stir for another 10min, then let it stand for 30min, add SnCl with a molar concentration of 1.4mol / L according to the titanium:tin molar ratio of 60:1 4 ·5H 2 O solution, stirred evenly, and aged for 24 hours to slowly polymerize the sol and colloidal particles. Transfer the aged sol to an autoclave and treat it at a constant temperature of 180°C for 24 hours, then cool the product in the autoclave to room temperature, wash the product after cooling with absolute ethanol repeatedly, then perform centrifugation, and dry the product after separation , the drying temperature is 60°C, and the product obtained after drying is ground to obtain SnO 2 -TiO 2 Composite nano photocatalyst...

Embodiment 2

[0036] Mix 57ml of tetra-n-butyl titanate, 266ml of absolute ethanol, and 19ml of glacial acetic acid evenly, and add 57ml of dilute nitric acid (nitric acid: water = 1:10) dropwise under constant stirring to adjust the pH to 3, and continue stirring for 15 minutes. , add 30ml of deionized water, stir for another 10min, then let it stand for 30min, add SnCl with a molar concentration of 1.4mol / L according to the titanium:tin molar ratio of 55:1 4 ·5H 2 O solution, stirred evenly, and aged for 20 hours to slowly polymerize the sol and colloidal particles. Transfer the aged sol to an autoclave and treat it at a constant temperature of 180°C for 22 hours, then cool the product in the autoclave to room temperature, wash the product after cooling with absolute ethanol repeatedly, then perform centrifugation, and dry the product after separation , the drying temperature is 55°C, and the product obtained after drying is ground to obtain SnO 2 -TiO 2 Composite nano photocatalyst. ...

Embodiment 3

[0038] Mix 65ml of tetra-n-butyl titanate, 273ml of absolute ethanol, and 39ml of glacial acetic acid evenly, and add 13ml of dilute nitric acid (nitric acid: water = 1:10) dropwise under constant stirring to adjust the pH value to 3, and continue stirring for 15 minutes. , add 30ml of distilled water, stir for 10min, then let it stand for 30min, add SnCl with a molar concentration of 1.4mol / L according to the titanium:tin molar ratio of 65:1 4 ·5H 2 O solution, stirred evenly, and aged for 28 hours to slowly polymerize the sol and colloidal particles. Transfer the aged sol to an autoclave and treat it at a constant temperature of 180°C for 27 hours, then cool the product in the autoclave to room temperature, wash the product after cooling with absolute ethanol repeatedly, then perform centrifugation, and dry the product after separation , the drying temperature is 65°C, and the product obtained after drying is ground to obtain SnO 2 -TiO 2 Composite nano photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com