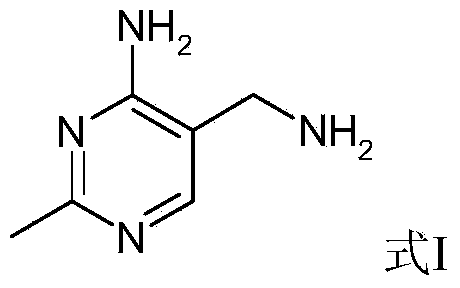

Portable synthesis method for preparing 2-methyl-4-amino-5-aminoethylpyrimidine through one-step cyclization reaction

A technique for the synthesis of aminomethylpyrimidine and its synthesis method, which is applied in the field of convenient synthesis of 2-methyl-4-amino-5-aminomethylpyrimidine, and can solve the problems of difficult removal of o-chloroaniline, high consistency requirements, and low utilization rate. Ideal and other issues, to achieve the effects of production protection, high yield, and saving raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

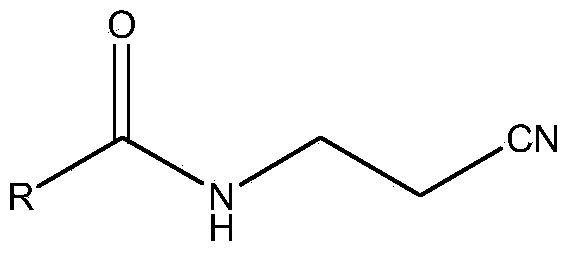

[0038] Embodiment 1: the preparation of raw material 3-acylaminopropionitrile

[0039] Take 3-formylaminopropionitrile as an example:

[0040] Add 70 grams (1.0 moles) of 3-aminopropionitrile and 81.4 grams (1.1 moles) of ethyl formate to a 500 milliliter four-neck flask, react at room temperature at 20 ° C, and use gas phase detection to complete the reaction; after the reaction is completed, rectify to obtain 94.1 grams 3-Formylaminopropionitrile, gas phase purity 99.7%, yield 96.0%.

[0041] According to the above-mentioned method, replace the ethyl formate in embodiment 1 with ethyl acetate, n-ethyl propionate, n-butyrate ethyl ester, isobutyrate ethyl ester, ethyl benzoate or o-methylbenzoate ethyl ester respectively, 3-acetylaminopropionitrile, 3-propionylaminopropionitrile, 3-n-propylformylaminopropionitrile, 3-isopropylformylaminopropionitrile, 3-phenylformylaminopropionitrile can be obtained respectively Or 3-o-methylphenylformylaminopropionitrile. Reserve as a raw...

Embodiment 2

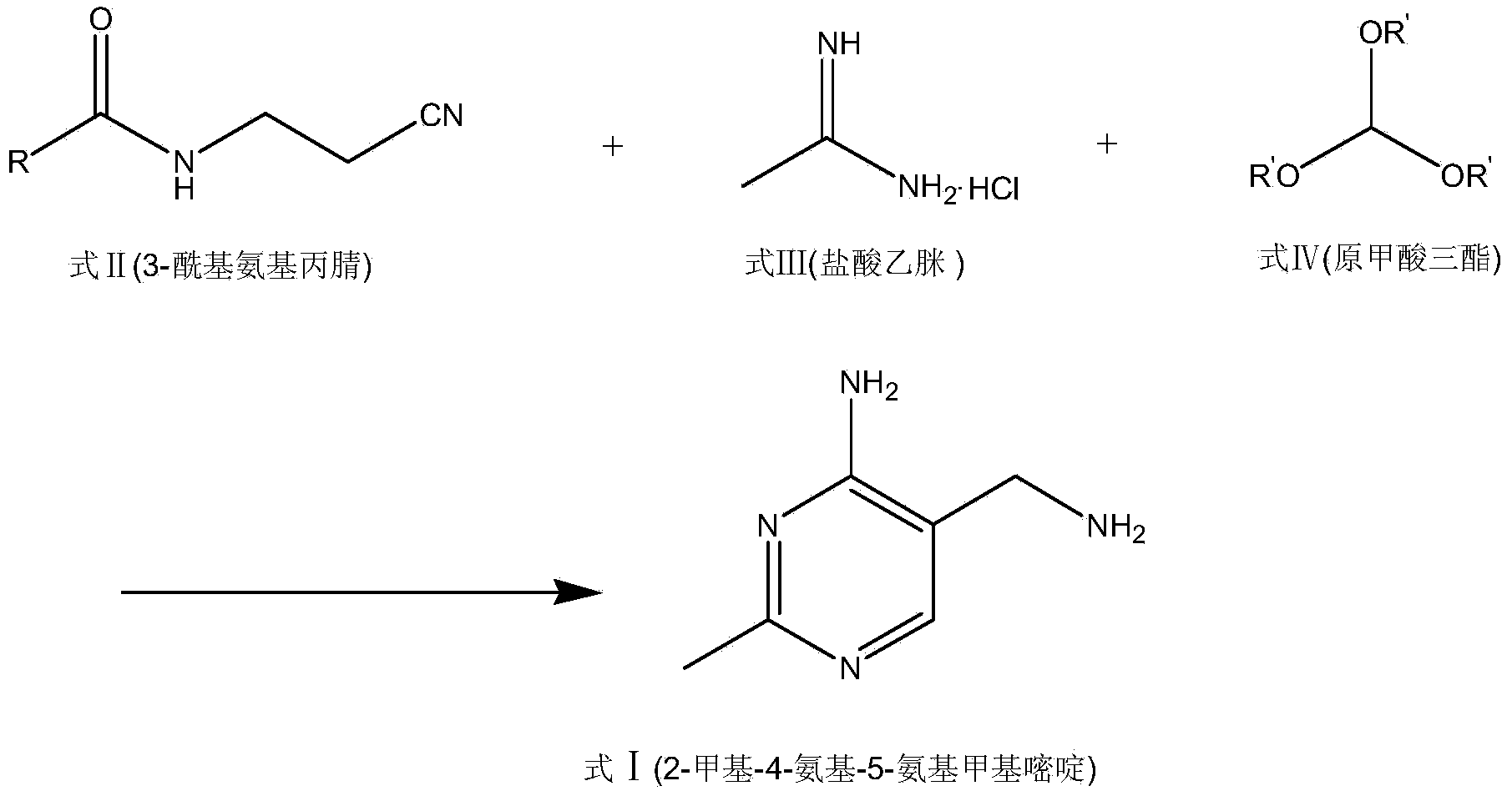

[0042] Embodiment 2: The preparation of 2-methyl 4-amino-5-aminomethylpyrimidine, taking 3-formamidopropionitrile as an example, the reaction formula is as follows:

[0043]

[0044] The synthesis steps are as follows:

[0045] Add 360 grams of isopropanol, 98 grams of 3-formamidopropionitrile, 104 grams of acetamidine hydrochloride, and 115 grams of trimethyl orthoformate into a 1000 milliliter glass reaction vessel, stir to dissolve; then add 12.2 grams of anhydrous zinc chloride ; Heating, the internal temperature rose to 85 ~ 90 ℃; stirring the reaction, the use of gas phase detection 3-acetamidopropionitrile reaction is complete.

[0046] After the reaction is completed, cool slightly, add a solution of 90 grams of sodium hydroxide and 200 grams of isopropanol to the obtained reaction liquid, react at 90-95 ° C, and use the liquid phase to detect the conversion of the intermediate until the reaction is completed. The purity and yield of the product 2-methyl-4-amino-5-am...

Embodiment 3

[0049] As described in Example 1, the difference is that 112 grams of 3-acetamidopropionitrile is used to replace 98 grams of 3-formamidopropionitrile in Example 1 for the reaction. The preparation steps and conditions are the same as in Example 1, and the resulting product The purity and yield are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com