Hollow magnetic polymer composite microsphere, and preparation method and application thereof

A technology of composite microspheres and polymers, which is applied in the field of hollow magnetic polymer composite microspheres and its preparation, can solve the problems of short shelf life of composite microspheres, reduction of saturation magnetization, and limitation of biomedical applications, so as to facilitate popularization application, high saturation magnetization, and the effect of improving magnetic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of Superparamagnetic Fe by Co-precipitation 3 o 4 nanoparticles

[0037] Add 100 mL of deionized water into a 250 mL flask, continuously blow nitrogen into the water to remove oxygen, and heat to 50°C, add 1000 mg of FeCl under stirring conditions 2 4H 2 O, 2448 mg FeCl 3 ·6H 2 O, 11 mg SDBS and 35 mL NH 4 OH, keep stirring under the protection of nitrogen and raise the temperature to 80°C, keep stirring for 1 h, cool to room temperature naturally, wash the precipitated black product with deionized water, and perform magnetic separation by applying an external magnetic field, discard the supernatant, The precipitate was washed with deionized water again, and magnetically separated by an external magnetic field, so that the pH was repeatedly washed to 7, at which time Fe 3 o 4 It can be well dispersed in water to form a stable suspension of superparamagnetic nanoparticles. Thermogravimetric analysis showed that the resulting Fe 3 o 4 Th...

Embodiment 2

[0039] Example 2 Preparation of Superparamagnetic Fe by Co-precipitation 2 o 3 nanoparticles

[0040] Add 100 mL of deionized water into a 250 mL flask and heat to 50°C, add 4000 mg of FeCl under stirring 3 ·6H 2 O, 5.5 mg SDBS and 35 mL NH 4 OH, keep stirring and raise the temperature to 80°C, keep stirring and react for 1 h, cool down to room temperature naturally, wash the precipitate with deionized water, and conduct magnetic separation by applying a magnetic field, discard the supernatant, and use the precipitate again The precipitate was washed with deionized water, and magnetically separated by an external magnetic field, and washed repeatedly until pH = 7, at this time Fe 2 o 3 It can be well dispersed in water to form a stable suspension of superparamagnetic nanoparticles. Thermogravimetric analysis showed that the resulting Fe 2 o 3 The content of SDBS is about 0.5%.

[0041] A series of superparamagnetic Fe with SDBS content of 0.5-2% was prepared by adju...

Embodiment 3

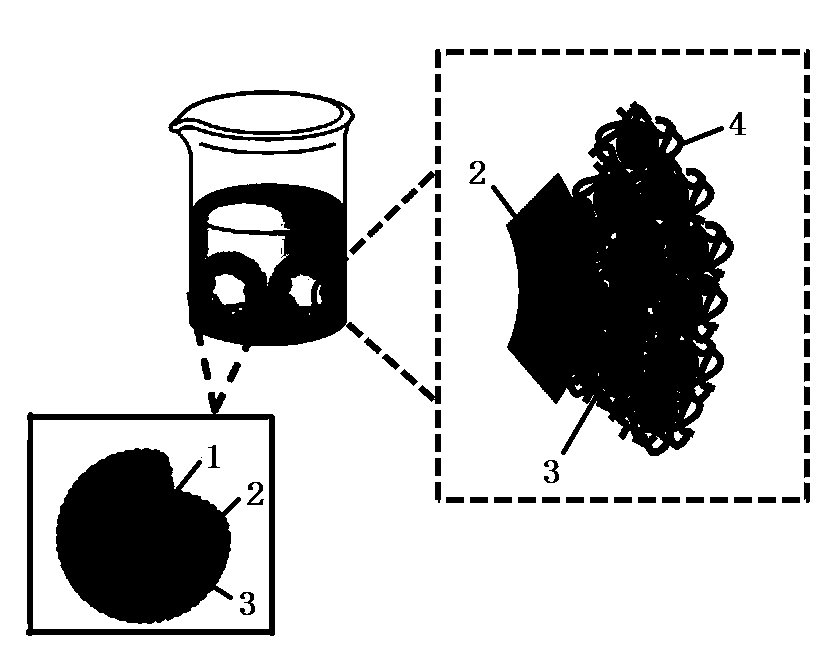

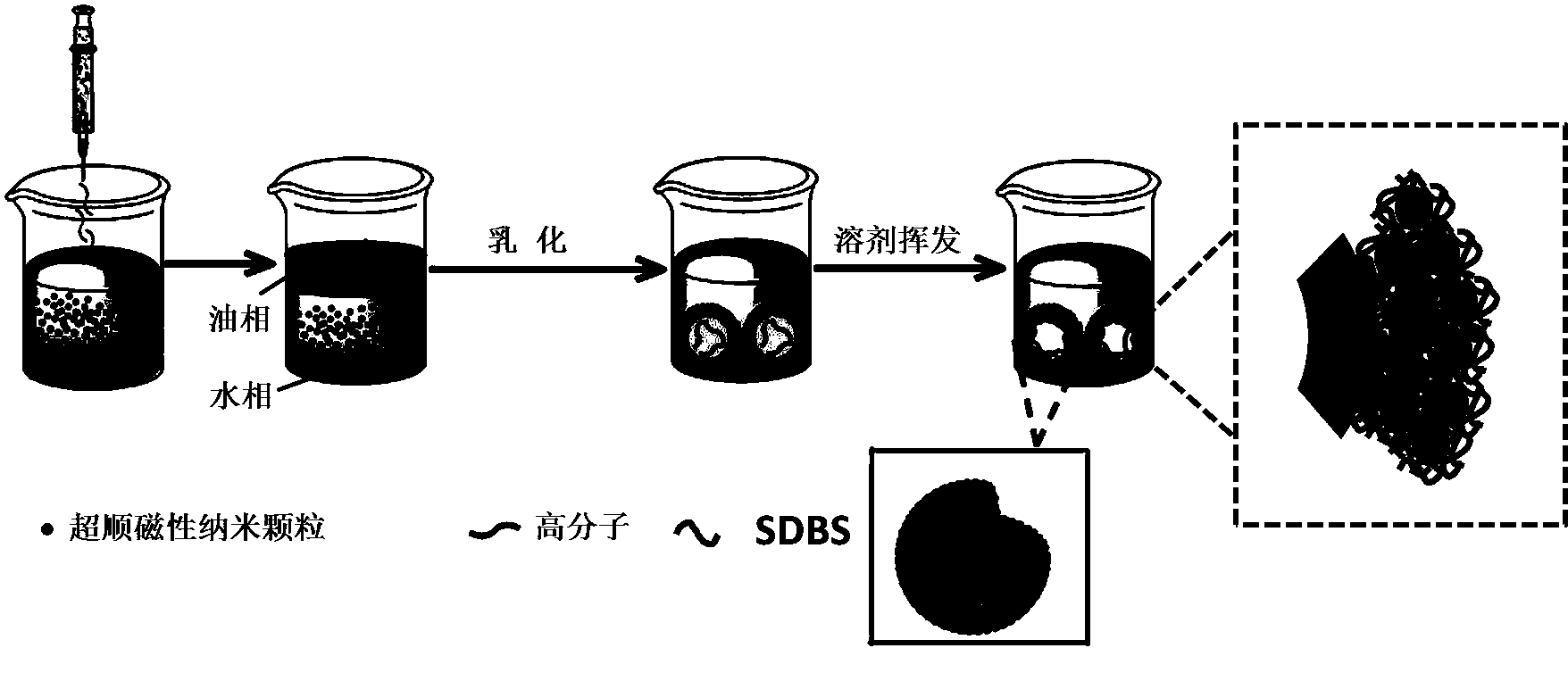

[0042] Example 3 Preparation of Hollow Magnetic Polymer Composite Microspheres

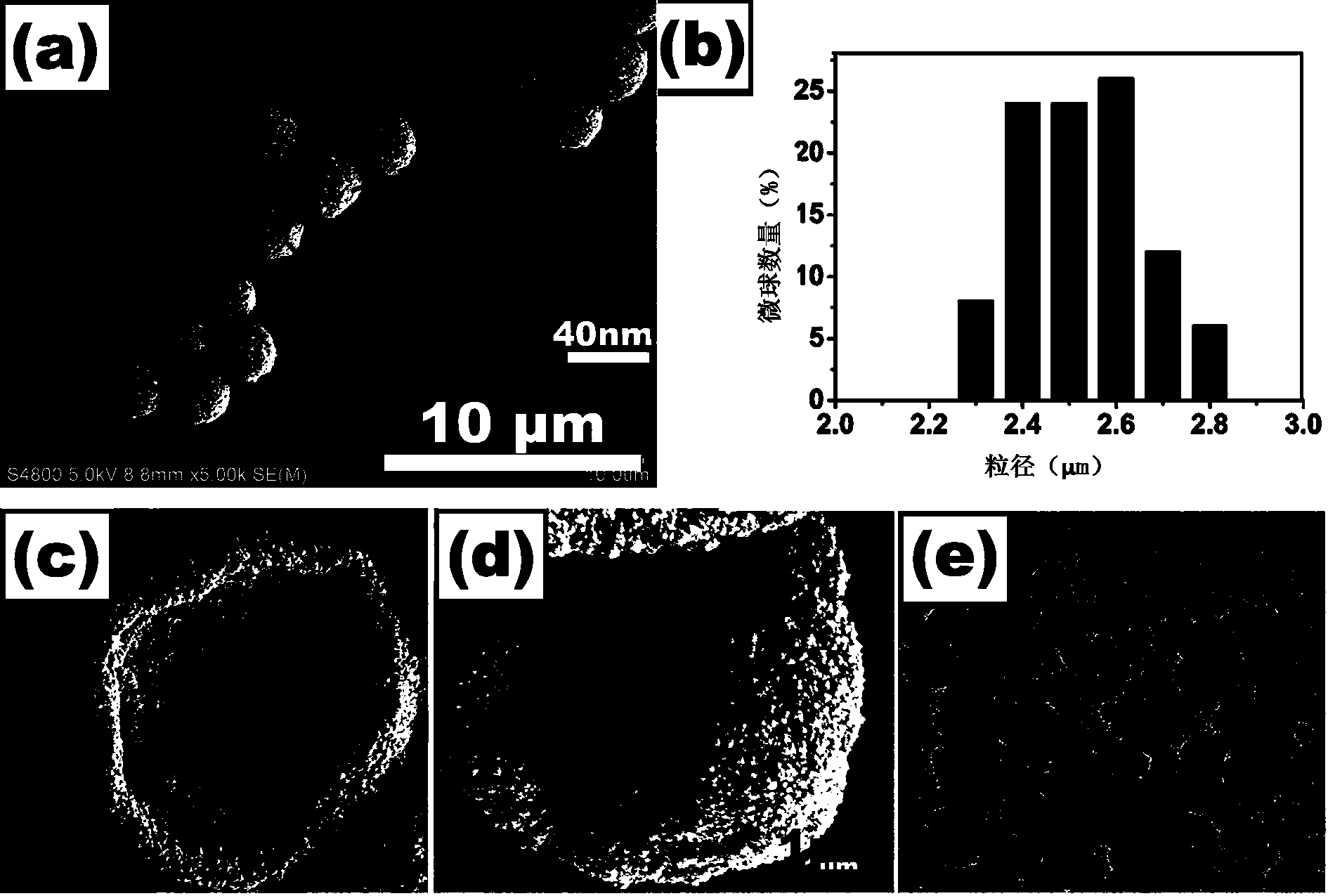

[0043] according to figure 2 For the procedure shown, 1 mL of CH containing 100 mg PLGA 2 Cl 2 The solution was added dropwise to the Fe prepared in 40 mL of Example 1. 3 o 4 In the suspension, Fe in the suspension 3 o 4 The concentration is 10 mg / mL, Fe 3 o 4 The content of SDBS in the medium is about 1%,; while adding dropwise, use a homogenizer to emulsify at 6500 rpm for 1 h, and then mechanically stir at room temperature at a speed of 800 rpm to make the solvent CH 2 Cl 2 Volatile. The obtained product was rinsed with deionized water and transferred to a centrifuge tube, centrifuged at 1500 rpm for 3 min, the supernatant was discarded, the precipitate was washed and centrifuged repeatedly, and washed and centrifuged repeatedly for 3 times. Finally, the synthesized PLGA / Fe 3 o 4 The composite microspheres are dispersed in water for later use.

[0044] The obtained composite mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com