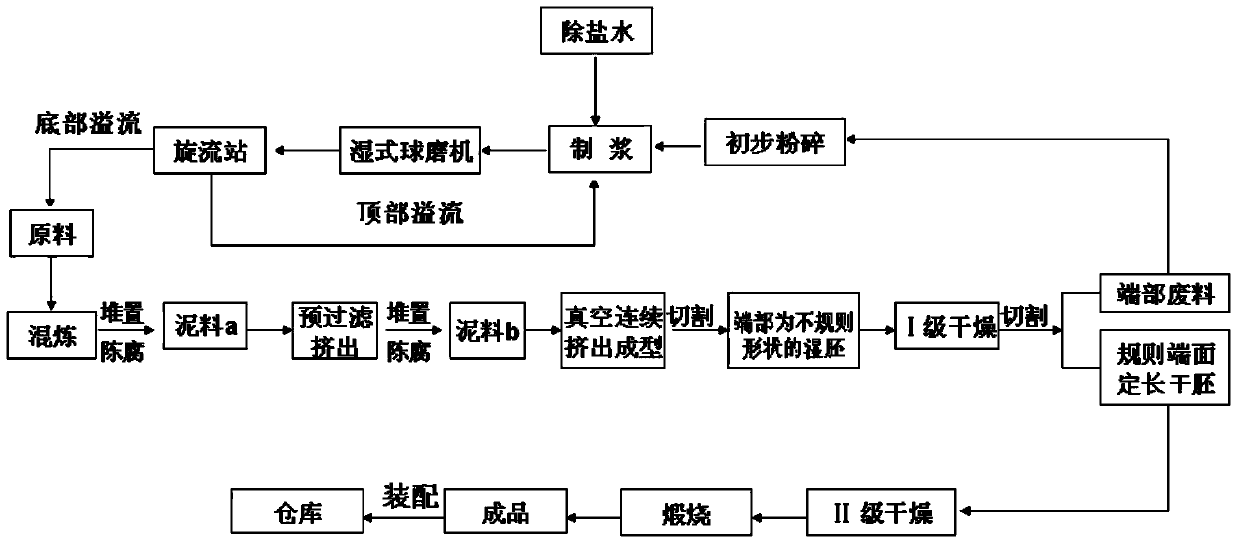

Preparation method of continuous extrusion SCR (Selective Catalytic Reduction) denitration honeycomb catalyst

A honeycomb catalyst, denitration technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. To achieve the effect of reducing resource consumption and reducing environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Mix 660g of titanium dioxide, 5g of vanadium pentoxide, 35g of tungsten trioxide and 300g of additives and stir evenly to obtain a mixed solution, wherein the additives are 3g of carboxymethylcellulose, 3g of polyoxyethylene, 1.5g of monoethanolamine, 6g of lactic acid, 36g glass fiber, 1.5g stearic acid, 57g ammonia water and 192g demineralized water. Add the above mixture to a mixer for mixing to obtain mud a with a moisture content of 28%, filter and pre-extrude the mud a, filter out various impurities brought in during the mixing process, and obtain a filter material , The diameter of the filter screen used is 650-750mm, and several small holes are opened, with a single hole of 3.5mm×0.7mm rectangular hole. The filter material is piled up again to be stale to obtain the mud material b, and the moisture content of the mud material b is 28%. The slime b was formed by vacuum continuous extrusion and cut during the continuous extrusion process to obtain a wet embryo wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com