Downdraft biomass gasification combustion cooking and heating furnace

A biomass and heating furnace technology, which is applied in heating methods, household stoves/stoves, solid heating fuels, etc., can solve the problems of high quality requirements of biomass fuels, substandard flue gas emissions, and small fuel application scope, etc. Inexpensive, easy to maintain, functional and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

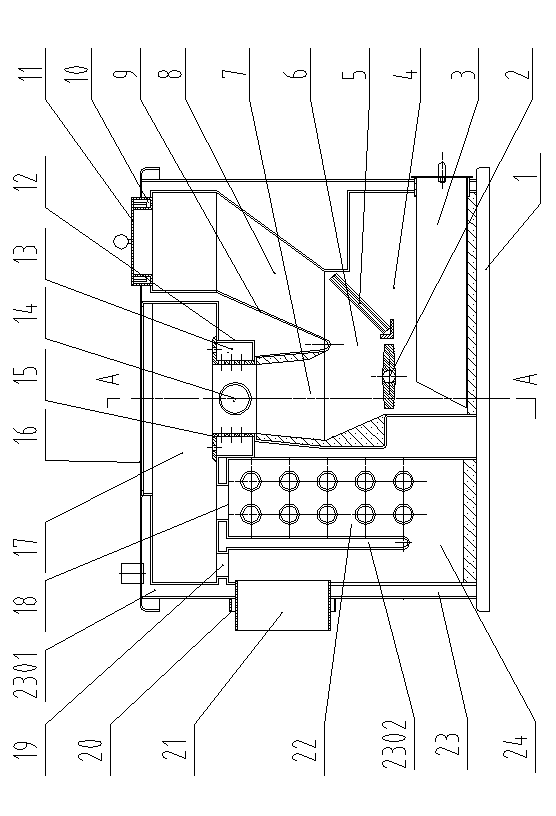

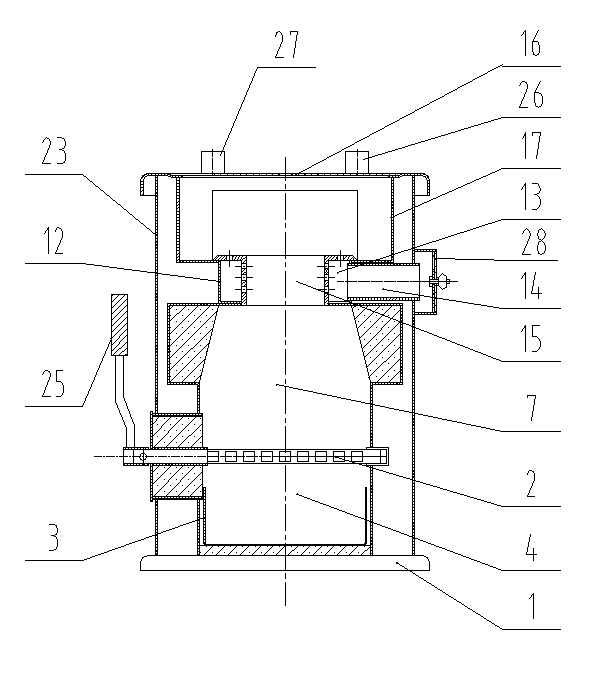

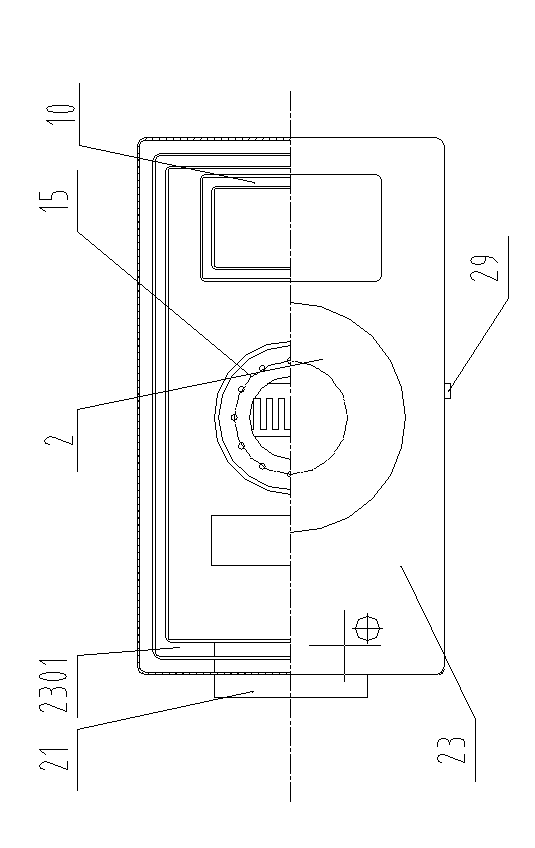

[0027] As shown in the figure, the present invention has a base 1, a furnace shell 23 is arranged on the base, a water jacket 2301 is arranged inside the furnace shell 23, and a primary air chamber 4 and a flue gas passage 24 are arranged in the furnace shell 23 from front to back, An ash outlet is provided at the bottom of the primary air chamber 4, an ash outlet drawer 3 is arranged in the ash outlet, and a gasification chamber 8 communicated with the entrance of the primary air chamber 4 and connected with the primary The combustion chamber 7 connected to the outlet of the air chamber 4, the gasification chamber 8 is inclined and its horizontal inclination angle is 30°-60°, which is 50° in the present embodiment, and the gasification chamber 8 and the combustion chamber 7 are formed between the gasification chamber 8 and the combustion chamber 7. The V-shaped water tank 9 communicated with the cover 2301, the V-shaped water tank 9 connects and separates the gasification cham...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com